LED chip and cutting method thereof

A technology of LED chips and cutting methods, which is applied to electrical components, circuits, abrasives, etc., can solve problems such as low yield rate, abnormal photoelectric characteristics, and low luminous efficiency of LED chips, so as to improve yield rate, avoid edge cracking, and overall luminescence The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

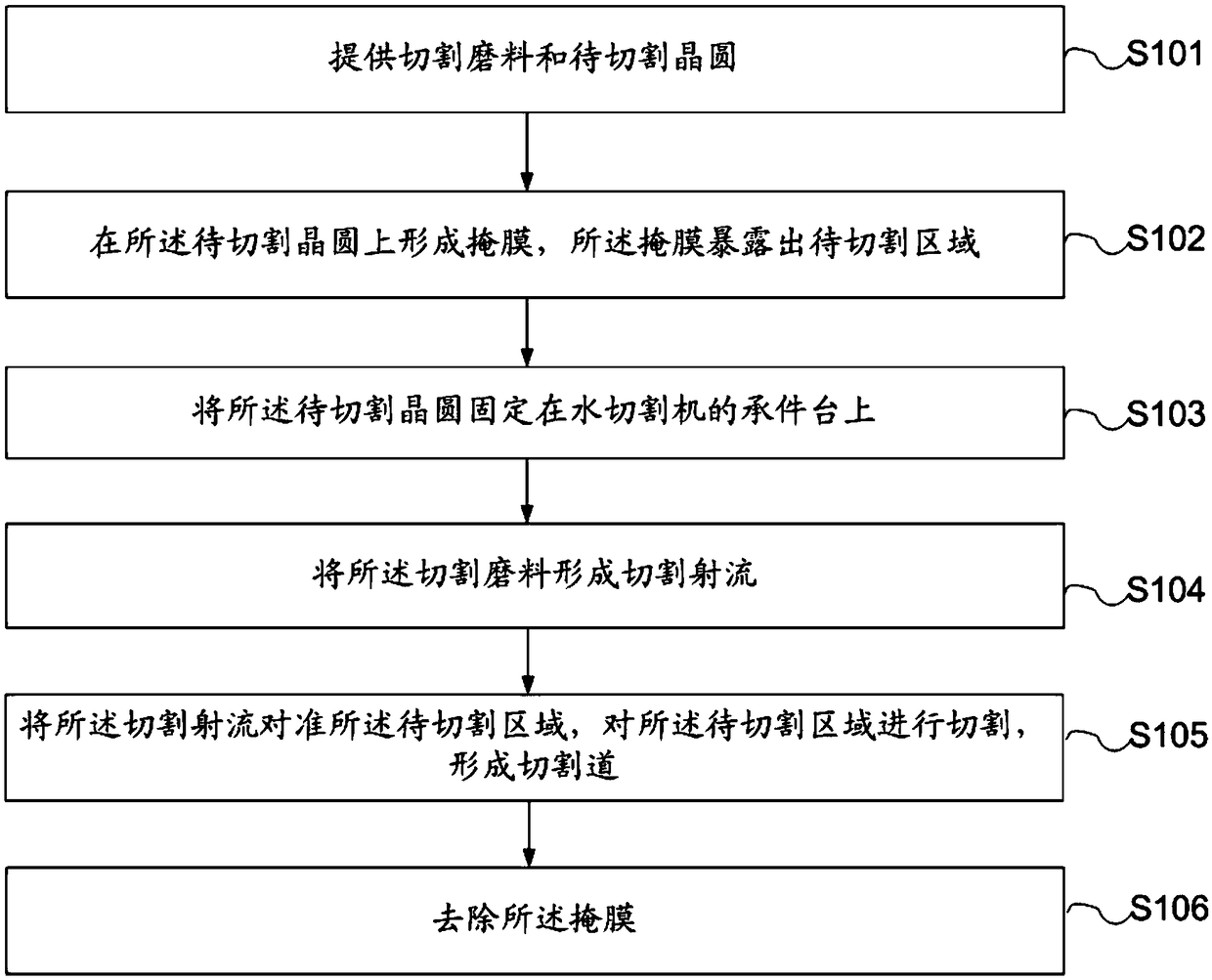

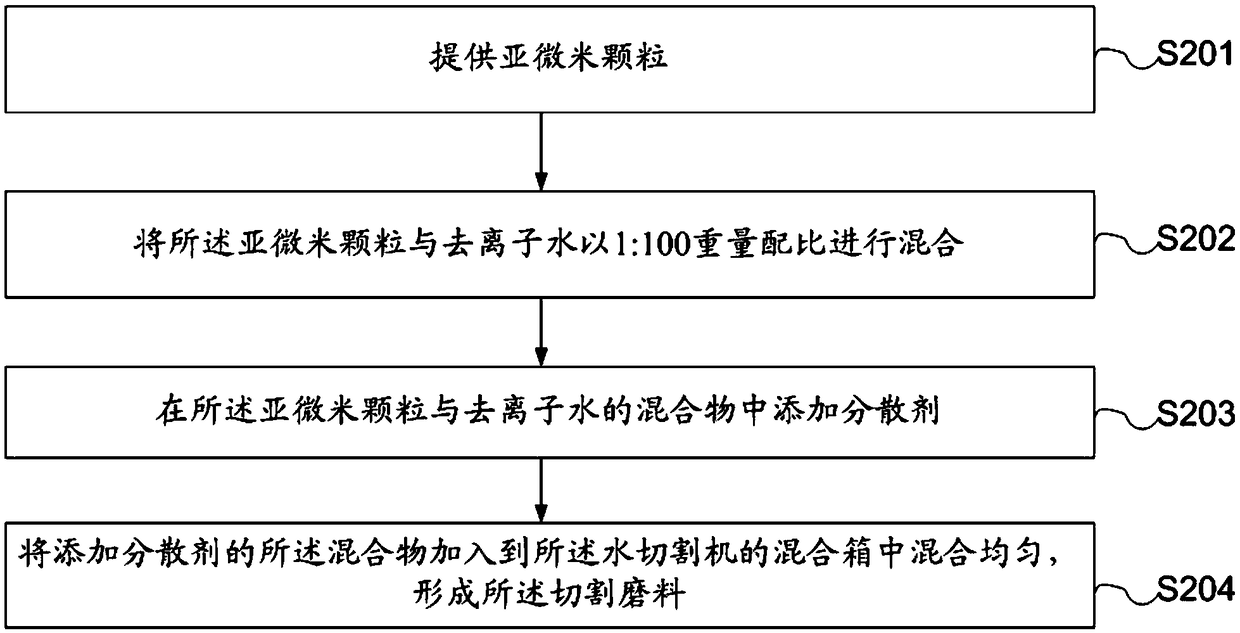

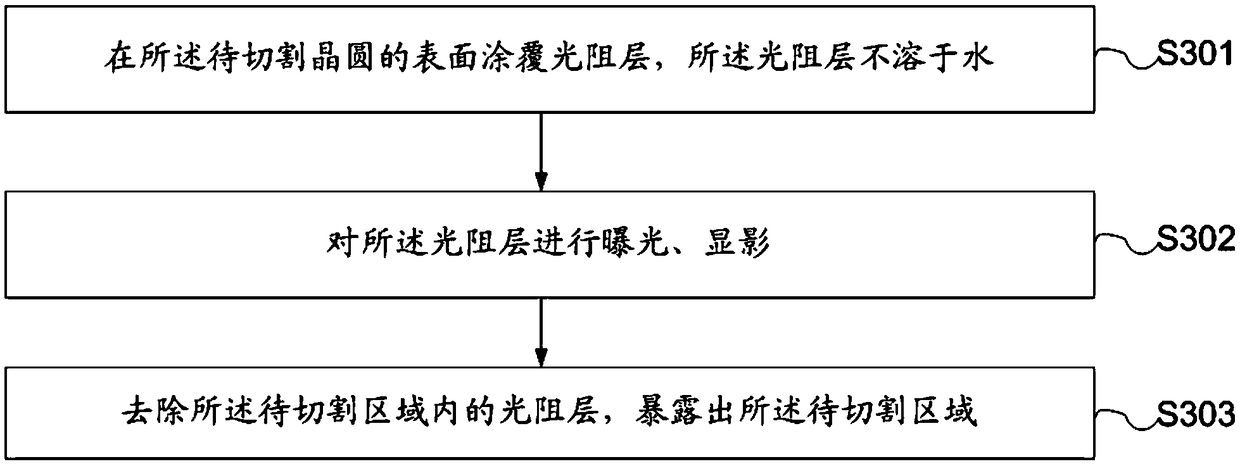

Method used

Image

Examples

Embodiment Construction

[0041] As mentioned in the background technology section, the LED chips obtained by the chip dicing method in the prior art have low luminous efficiency, abnormal photoelectric characteristics, and a low yield rate.

[0042] The inventors found that the reason for the above phenomenon is that the epitaxial layer of the LED wafer is mostly brittle materials such as AlGaInP, GaAs, GaP; The phenomenon of edge chipping and the generation of cutting residue; resulting in a decrease in yield. Moreover, the severity of cracking is closely related to the use status of the blade, which will cause inconsistency in the cutting quality of the product; and during the high-energy thermal processing of the laser, the high-temperature molten residue splashed out conducts the PN junction in the LED chip, causing the LED chip to leak electricity , In addition, because the black molten residue adhering to the side wall of the chip will block the emission of light, the overall luminous efficiency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com