A kind of aluminum alloy sheet production method

A production method and technology of aluminum alloy, which is applied in the field of aluminum alloy, can solve the problems of high production cost of aluminum alloy sheet, affect the quality and precision of parts, and poor uniformity of sheet metal, so as to achieve low equipment requirements, improve yield rate, and avoid component segregation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare a 2A12 aluminum alloy plate with a thickness of 0.5mm;

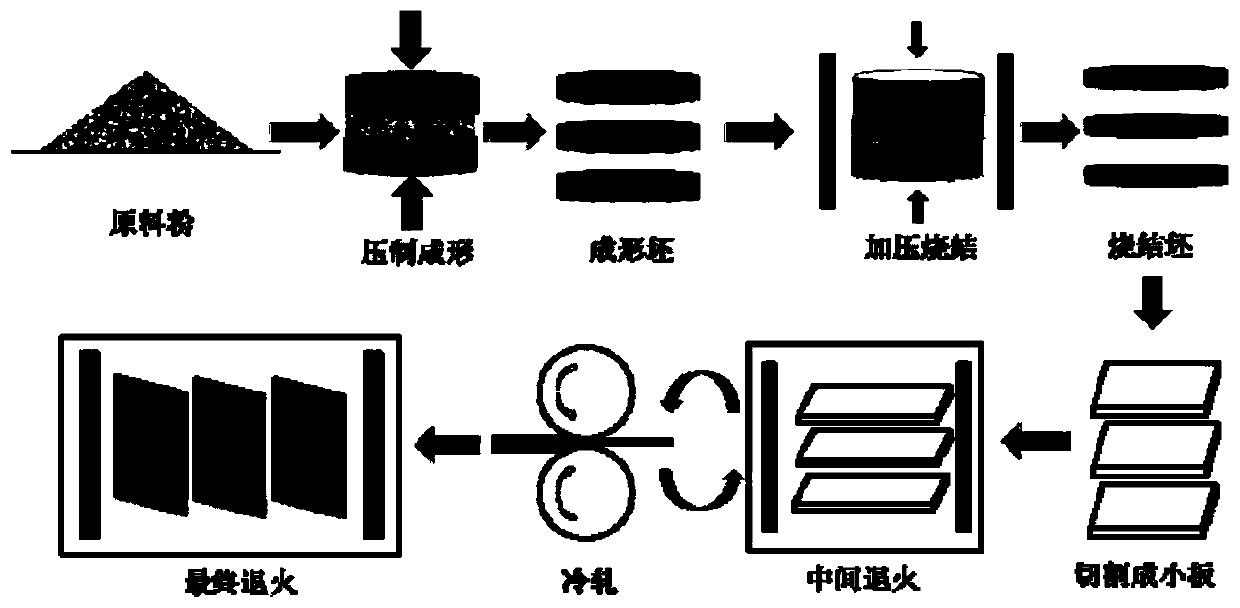

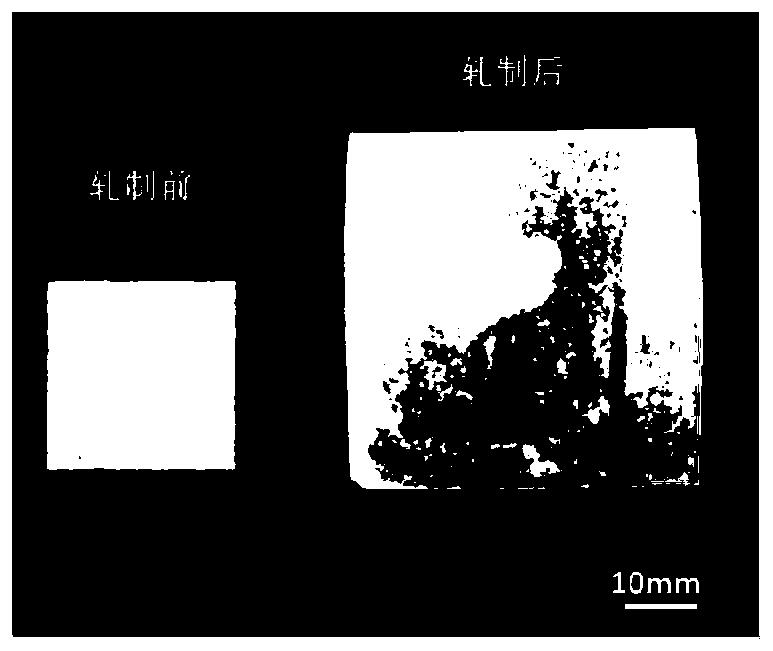

[0044] According to the production method of the present invention, the 250-300 mesh spherical 2A12 aluminum alloy powder (nearly spherical powder prepared by water atomization method) produced by Changsha Tianjiu Metal Material Co., Ltd. is used as raw material powder (its chemical composition meets the requirements of GB / T3190) , the sheet production process is as follows figure 1As shown, the powder is pressed into a steel mold to prepare a green body (the thickness of the green body is 3 mm), and the green body is sintered in a high-vacuum precision vacuum hot-press furnace to prepare a cold-rolled sheet material (sintering temperature 575 ° C, time 120 min, pressure 10MPa), the sintered billet was cut into small square plates (thickness 2.5mm) by wire cutting, and the surface was cleaned, and the small square plates were rolled on a reversible two-roll cold rolling mill, and pressed in a single pass ...

Embodiment 2

[0047] Prepare a 2A12 aluminum alloy plate with a thickness of 1.0 mm;

[0048] Its preparation process is consistent with the process of Example 1, see the thin plate production process of Example 1 (the total deformation of the plate is 60%) for details. The tensile strength of the obtained sheet was 311.59 MPa.

[0049] The above experiment was repeated 100 times, and the yield was 99%. It can be seen from Examples 1 and 2 that the total deformation of the rolled plate affects its tensile strength.

Embodiment 3

[0051] Prepare a 2A12 aluminum alloy plate with a thickness of 0.5mm;

[0052] According to the production method of the present invention, the 250-300 mesh spherical 2A12 aluminum alloy powder (nearly spherical powder prepared by water atomization method) produced by Changsha Tianjiu Metal Material Co., Ltd. is used as raw material powder (its chemical composition meets the requirements of GB / T3190) , the sheet production process is as follows figure 1 As shown, the powder is pressed into a steel mold to prepare a green body (the thickness of the green body is 3 mm), and the green body is sintered in a high-vacuum precision vacuum hot-press furnace to prepare a cold-rolled strip raw material (sintering temperature 535 ° C, time 120 min, The pressure is 10MPa), and the sintered billet is cut into small square plates (thickness 2.5mm) by wire cutting, and the surface is cleaned, and the small square plates are rolled on a reversible two-roll cold rolling mill, and the single-pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com