Non-oriented silicon steel and production method thereof

A production method and technology of oriented silicon steel, applied in the field of metal material processing, can solve the problems of reduced production rolling passes, reduced production difficulty, and high production difficulty, and achieve reduction in reduction, low difficulty, and large grain size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

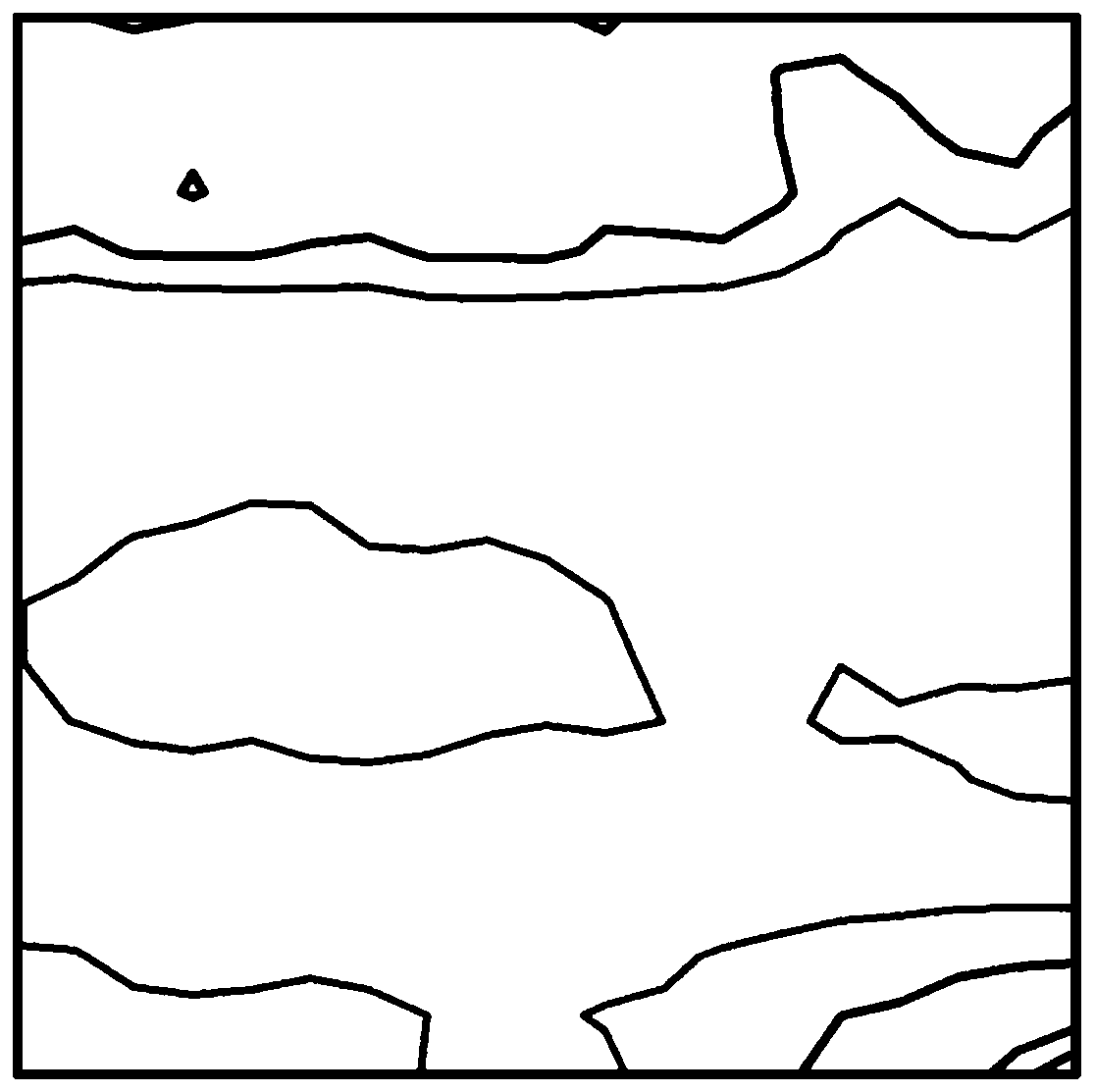

Image

Examples

Embodiment 1

[0049] 1) Smelting

[0050]The chemical composition of molten steel is: C: 0.02wt%, Si: 3.50wt%, Mn: 0.20wt%, Al: 0.002wt%, Sn: 0.10wt%, Sb: 0.04wt%, N: 0.002wt%, S: 0.002 wt%, O: 0.003wt%, Cu: 0.30wt%, Cr: 0.60wt%, Ni: 0.07wt%, V: 0.03wt%, Nb: 0.01wt%, Ti: 0.02wt%, P: 0.10wt% , and the rest are Fe and unavoidable impurities.

[0051] 2) Thin strip continuous casting

[0052] The molten steel qualified for smelting is continuously cast into a cast strip with a thickness of 2.5mm through a pair of crystallization rollers rotating in opposite directions. The casting temperature of the molten steel is 1620°C and the continuous casting speed is 58m / min.

[0053] 3) On-line hot rolling and coiling of cast strip

[0054] The cast strip is rolled into a 1.5mm thick thin strip steel through 2-pass on-line hot rolling and coiled into a coil. The hot rolling temperature is 950°C, and the hot strip coiling temperature is 580°C.

[0055] 4) Leveling or straightening

[0056] The hot-...

Embodiment 2

[0062] 1) Smelting

[0063] The chemical composition of molten steel is: C: 0.035wt%, Si: 2.10wt%, Mn: 0.40wt%, Al: 0.035wt%, Sn: 0.03wt%, Sb: 0.20wt%, N: 0.003wt%, S: 0.005 wt%, O: 0.005wt%, Cu: 0.02wt%, Cr: 0.30wt%, Ni: 0.10wt%, V: 0.08wt%, Nb: 0.06wt%, Ti: 0.01wt%, P: 0.02wt% , and the rest are Fe and unavoidable impurities.

[0064] 2) Thin strip continuous casting

[0065] The molten steel qualified for smelting is continuously cast into a cast strip with a thickness of 2.1 mm through a pair of counter-rotating crystallization rollers. The casting temperature of the molten steel is 1580° C. and the continuous casting speed is 72 m / min.

[0066] 3) On-line hot rolling and coiling of cast strip

[0067] The cast strip is rolled into a 1.9mm thick thin steel strip through one pass of on-line hot rolling and coiled into a coil. The hot rolling temperature is 880°C, and the hot strip coiling temperature is 640°C.

[0068] 4) Leveling or straightening

[0069] The hot-roll...

Embodiment 3

[0075] 1) Smelting

[0076] The chemical composition of molten steel is: C: 0.008wt%, Si: 0.40wt%, Mn: 1.20wt%, Al: 0.50wt%, Sn: 0.05wt%, Sb: 0.08wt%, N: 0.005wt%, S: 0.003 wt%, O: 0.002wt%, Cu: 0.50wt%, Cr: 0.06wt%, Ni: 0.02wt%, V: 0.01wt%, Nb: 0.02wt%, Ti: 0.07wt%, P: 0.07wt% , and the rest are Fe and unavoidable impurities.

[0077] 2) Thin strip continuous casting

[0078] The molten steel qualified for smelting is continuously cast into a cast strip with a thickness of 1.4 mm through a pair of counter-rotating crystallization rollers. The casting temperature of the molten steel is 1680° C. and the continuous casting speed is 92 m / min.

[0079] 3) On-line hot rolling and coiling of cast strip

[0080] The cast strip is rolled into 1.0mm thick thin steel strip through 3 passes of on-line hot rolling and coiled into coils. The hot rolling temperature is 1120°C, and the hot rolled strip coiling temperature is 720°C.

[0081] 4) Leveling or straightening

[0082] The hot-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com