Rolling method for reducing edge cracking of continuous rolling mill

A continuous rolling mill and continuous rolling technology, applied in the field of strip rolling, can solve problems such as broken strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make those skilled in the technical field of the application understand the application more clearly, the technical solution of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

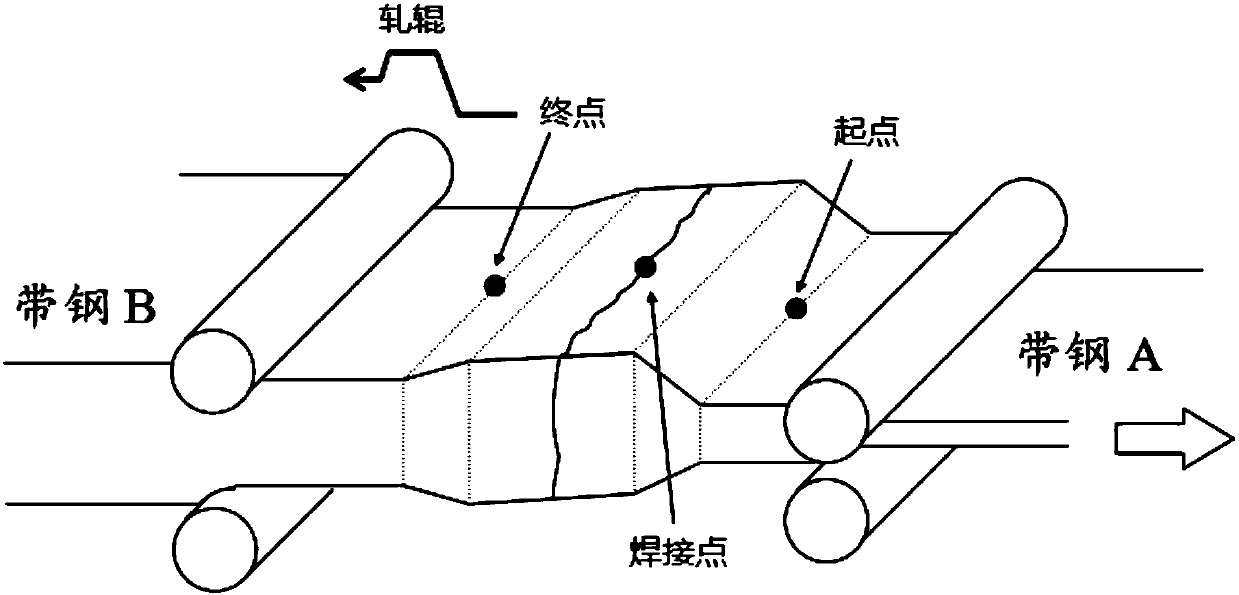

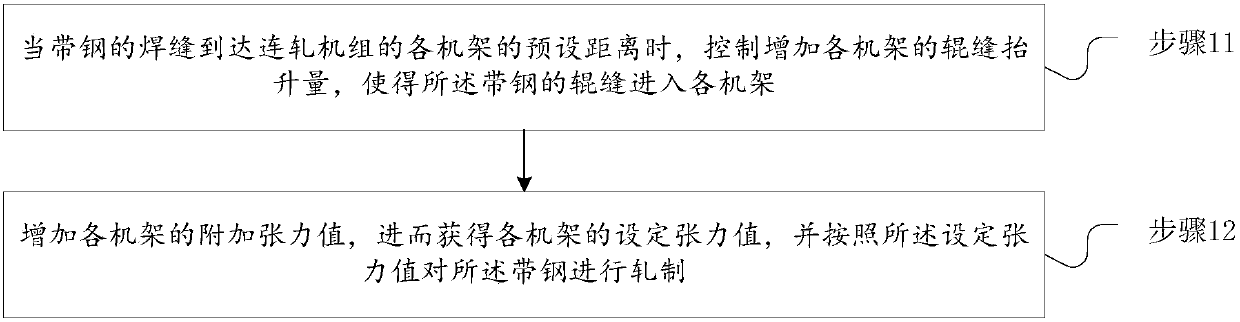

[0018] In the present invention, a rolling method for reducing side cracks in a continuous rolling mill is disclosed. By inputting the specific value of the roll gap variation, the method of increasing the thickness of the weld seam and reducing the rolling force in the weld seam area is disclosed, thereby avoiding the If it is too thin and the rolling force is too large, the edge cracks and the belt breakage accident will occur, so as to ensure the smooth progress of rolling. By adjusting the low-speed additional tension value of the rolling mill, the tensile stress in the weld area is reduced, thereby avoiding or reducing edge cracks, and preventing the edge cracks in the front and rear areas of the weld f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com