Two-phase stainless steel twin-roll thin strip cast rolling production technology

A duplex stainless steel, twin-roll thin strip technology, applied in metal rolling and other directions, can solve the problems of unresolved thin-gauge production, long production cycle of billet rolling, increased smelting difficulty and cost, and avoid edge cracking. and peeling defects, microstructure refinement, and the effect of reducing the cost of pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

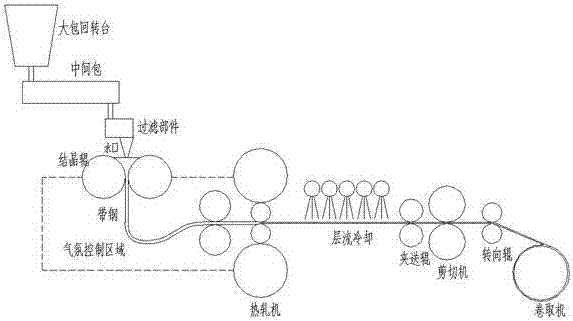

Image

Examples

Embodiment 1

[0024] A kind of thickness 1.0mm, steel type 2205 duplex stainless steel twin-roll thin strip casting and rolling production process, comprises the following steps:

[0025] (1) Hoist the molten steel with qualified composition to the ladle turret: hoist the duplex stainless steel molten steel refined in the LF ladle refining furnace to the ladle turret, and calm it down for 25 minutes;

[0026] (2) Molten steel is injected into the tundish: the tundish is blown with argon for 20 minutes to drive out the air in the tundish, and then the molten steel is injected from the ladle into the tundish through the long nozzle, and the superheat is controlled at 30°C; tundish covering agent;

[0027] (3) Twin-roll casting: molten steel is injected into the twin-roll casting machine through the submerged nozzle, the casting belt speed is 150m / min, the preset roll gap of the casting roll is 1.5mm, and the molten steel is protected by argon during the flow process. The pressure is 0.5MPa, ...

Embodiment 2

[0034] A kind of thickness 2.0mm, steel type 2304 duplex stainless steel, a kind of duplex stainless steel twin-roll strip casting and rolling production process comprises the following steps:

[0035] (1) Hoist the molten steel with qualified composition to the ladle turret: hoist the duplex stainless steel molten steel refined in the LF ladle refining furnace to the ladle turret, and calm it down for 20 minutes;

[0036] (2) Molten steel is injected into the tundish: the tundish is blown with argon for 15 minutes to drive out the air in the tundish, and then the molten steel is injected from the ladle into the tundish through the long nozzle, and the superheat is controlled at 30°C; tundish covering agent;

[0037] (3) Twin-roll casting: molten steel is injected into the twin-roll casting machine through the submerged nozzle, the casting belt speed is 100m / min, the preset roll gap of the casting rolls is 3.0mm, and a mixed gas of argon and hydrogen is used during the molten ...

Embodiment 3

[0044] A kind of thickness 4.0mm, steel grade 2507 super duplex stainless steel twin-roll strip casting and rolling production process, comprises the following steps:

[0045] (1) Hoist the molten steel with qualified composition to the ladle turret: hoist the duplex stainless steel molten steel refined in the LF ladle refining furnace to the ladle turret, and calm it down for 15 minutes;

[0046] (2) Molten steel is injected into the tundish: the tundish is blown with argon for 10 minutes to drive out the air in the tundish, and then the molten steel is injected from the ladle into the tundish through the long nozzle, and the superheat is controlled at 20°C; tundish covering agent;

[0047] (3) Twin-roll casting: molten steel is injected into the twin-roll casting machine through the submerged nozzle, the casting belt speed is 70m / min, the preset roll gap of the casting roll is 4.5mm, and argon gas is used for protection during the flow of molten steel. The pressure is 0.3MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com