Preparation method of accumulative stack rolling of nano-sheet phase reinforced tini-based alloy composite sheet

A technology of cumulative stacking and nanosheets, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of uneven distribution and size of reinforcement phase, and difficulty in melting of nanosheet phase-enhanced TiNi-based composites, etc. problems, to achieve the effect of low equipment requirements, easy regulation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] (1) Put the TiNi shape memory alloy foil in HF, HNO 3 And pickling in a mixed solution of deionized water.

[0030] (2) Polish the Nb foil with metallographic sandpaper to remove surface scale.

[0031] (3) The pickled TiNi shape memory alloy was ultrasonically cleaned in acetone for 15 minutes, and rinsed with alcohol.

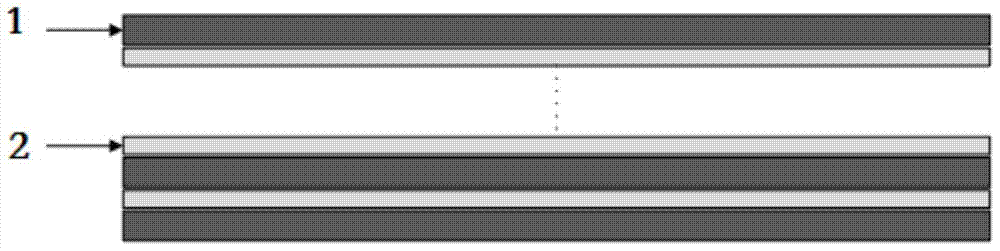

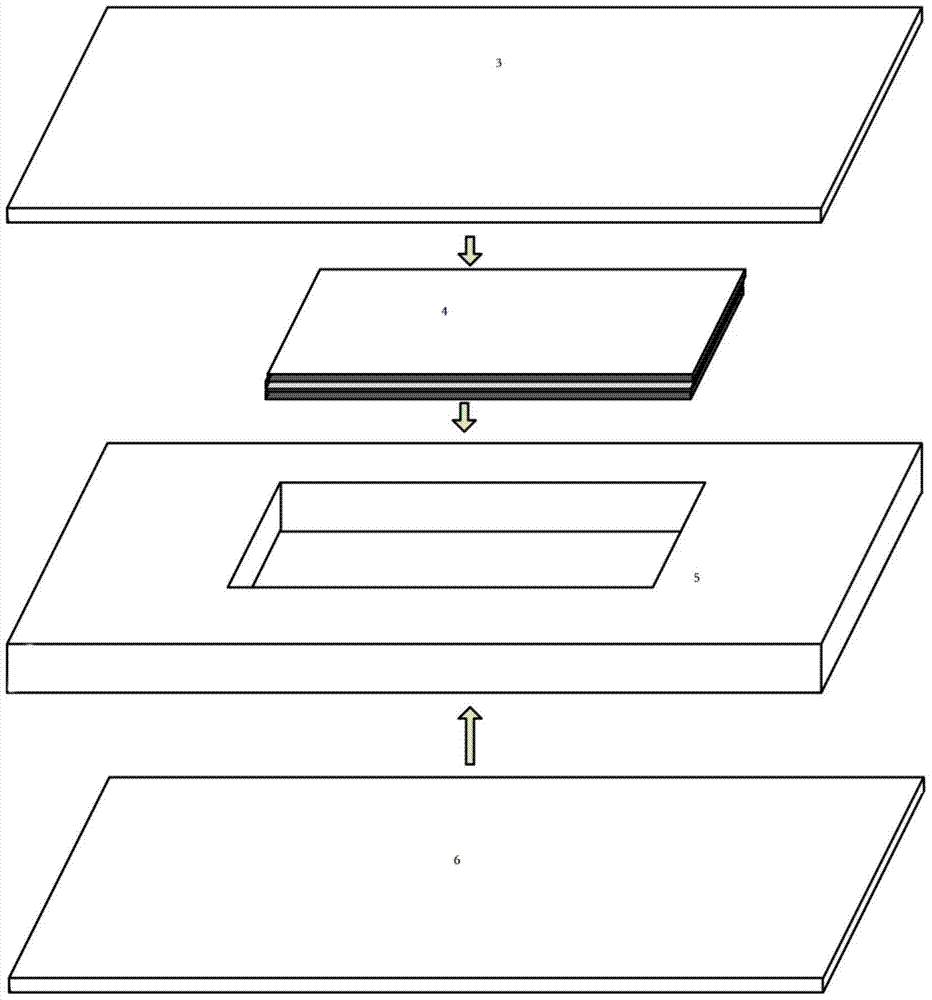

[0032] (4) Alternately stack pickled TiNi-based shape memory alloys and Nb foils and ensure that the outermost layer is a TiNi-based alloy sheet, mechanically fix both ends of the stacked sheet, and use stainless steel on the surface of the fixed sheet wrapping.

[0033] (5) The plate obtained in step (4) is placed under the rolling mill for rolling, the rolling temperature is 400°C-800°C, the heat preservation time for plate heating before rolling is 400°C, and the rolling pass is no more than 32 positive Integer, the deformation amount of a single pass is 50%.

[0034] (6) Vacuum annealing the rolled sheet in the range of 300° C. to 600° C. to ob...

specific Embodiment approach 2

[0036] The difference between this embodiment and Embodiment 1 is that the metal W foil is used in step (2) and step (4) in this embodiment.

specific Embodiment approach 3

[0038] The difference between this embodiment and Embodiment 1 is that the metal Ag foil is used in step (2) and step (4) of this embodiment.

[0039] Finally, it should be noted that the stainless steel sheath in step (5) of the present invention can be replaced by a pure Ti sheath.

[0040] Advantages of the present invention are verified below by examples.

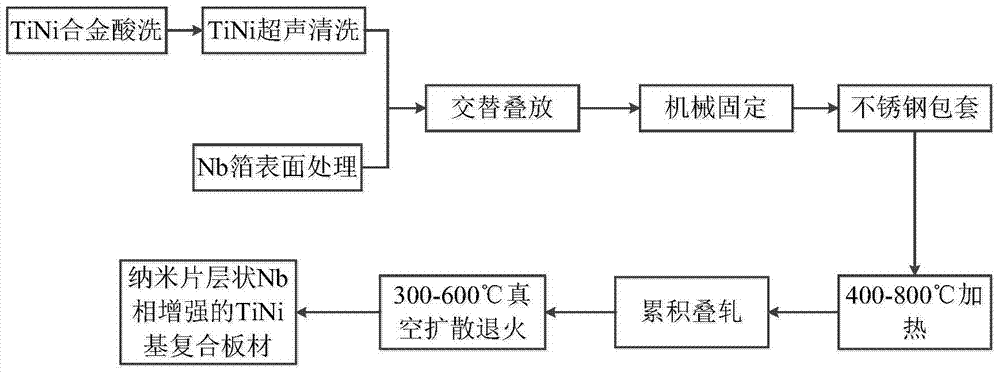

[0041] combine figure 1 , the technical route mainly includes:

[0042] (1) Change the composition to Ti 48.8 Ni 51.2 The shape memory alloy foil is placed in HF, HNO with a volume percentage of 1:2:10 3 And pickling in a mixed solution of deionized water, the final thickness of the foil is 0.6mm.

[0043] (2) Polish the Nb foil with metallographic sandpaper to remove the surface oxide skin, and the final thickness is 0.2mm.

[0044] (3) The pickled TiNi shape memory alloy was ultrasonically cleaned in acetone for 15 minutes, and rinsed with alcohol.

[0045] (4) Alternately stack pickled TiNi shape memory alloys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com