A kind of preparation method of ti/al/cf layered composite material

A technology of layered composite materials and laminated materials, which is applied in the field of preparation of Ti/Al/Cf layered composite materials, can solve the problems of poor interface bonding, etc., and achieve the effects of high interface strength, good interface bonding, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

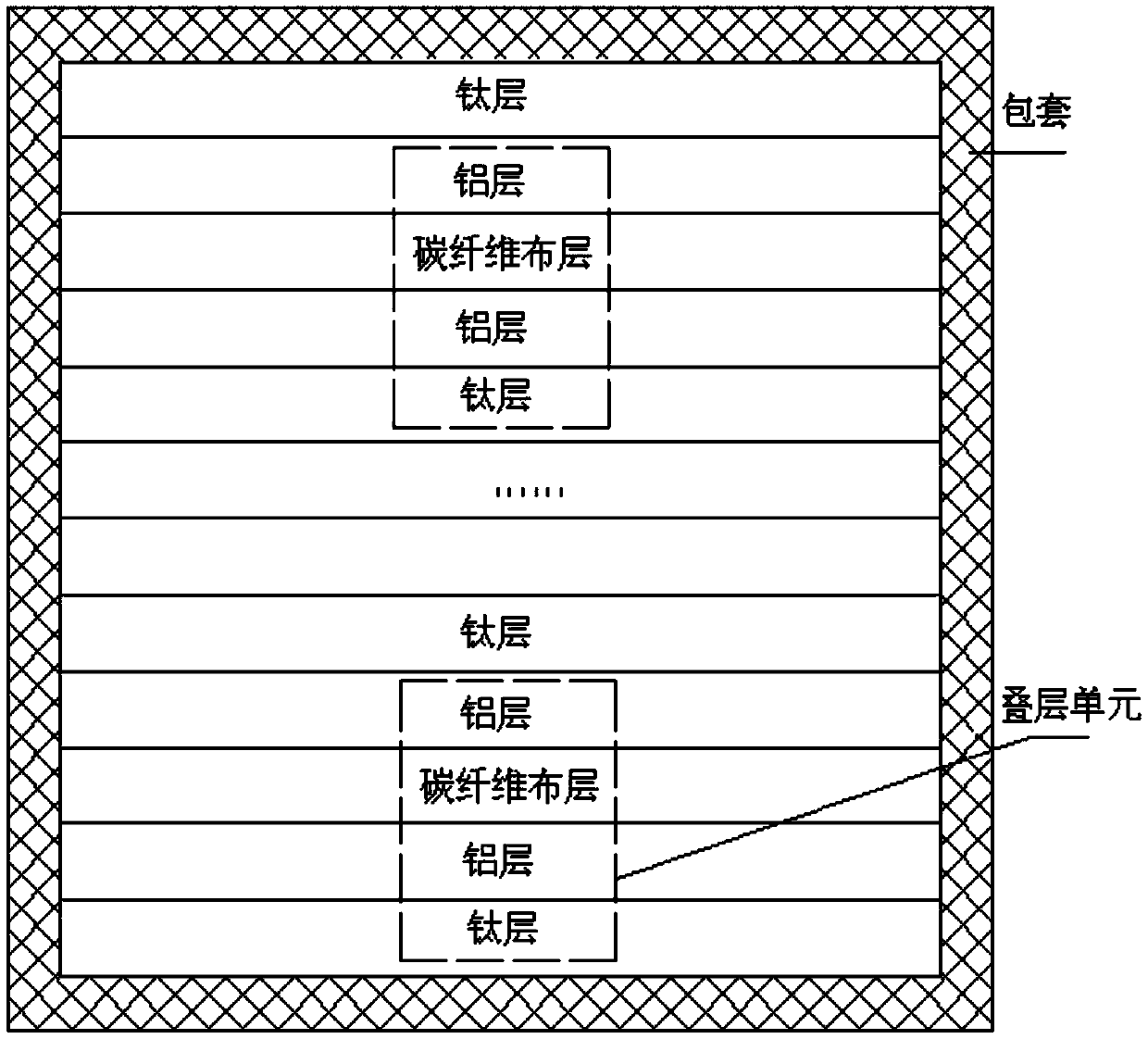

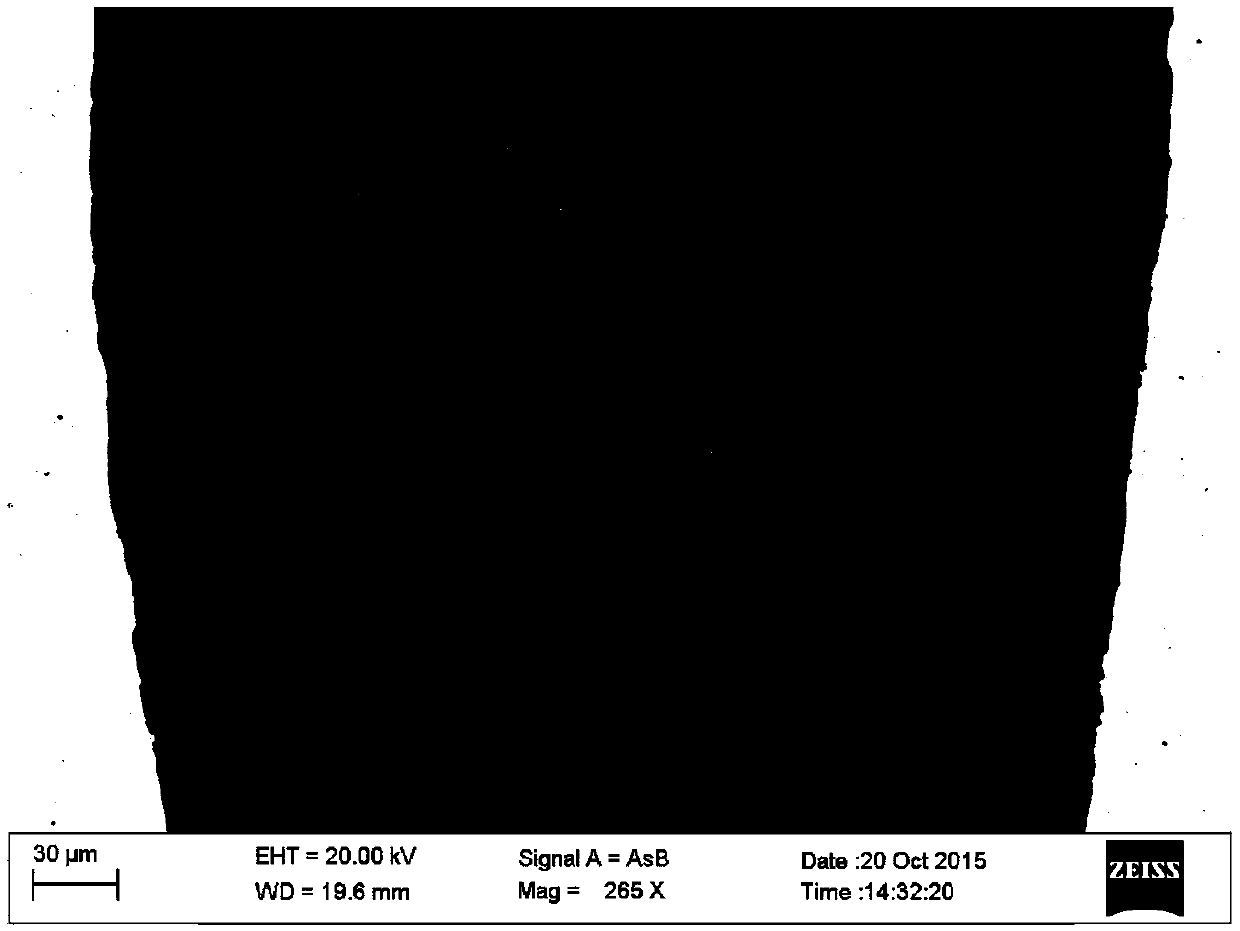

[0027] Specific Embodiment 1: A Ti / Al / Cf layered composite material in this embodiment is composed of a layered core material and a sheath, and the sheath is made of titanium foil with a thickness of 30 μm to 50 μm; the The layered core material consists of a titanium layer and several repeated lamination units from top to bottom, and the lamination units are aluminum layer, carbon fiber cloth layer, aluminum layer and titanium layer from top to bottom.

specific Embodiment approach 2

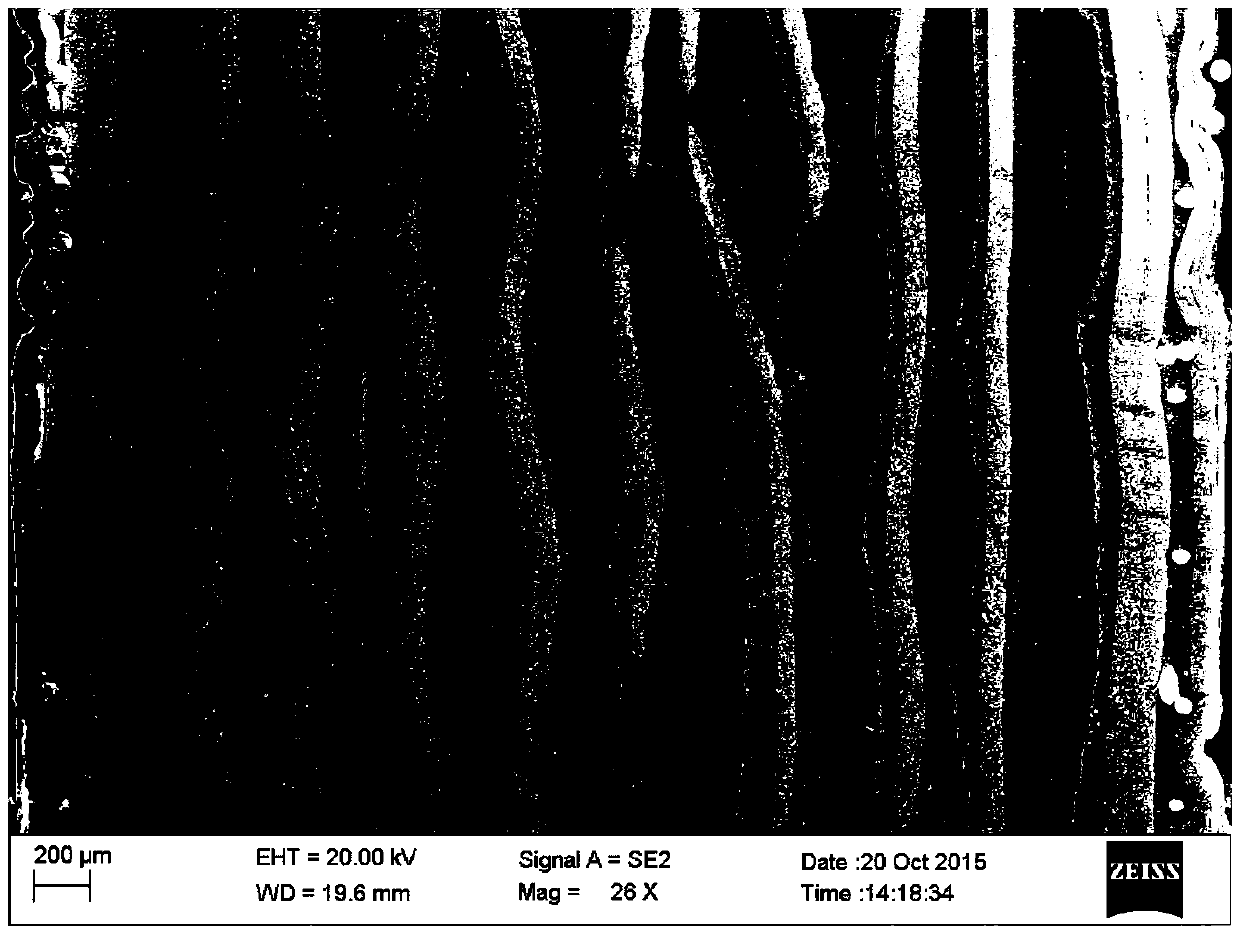

[0028] Embodiment 2: This embodiment is different from Embodiment 1: the carbon fiber cloth layer is unidirectional T300 series carbon fiber cloth with fiber tows of 1K, 3K, 6K and 12K, and the fiber tows are 1K, 3K, 6K and 12K unidirectional T700 series carbon fiber cloth or 1K, 3K, 6K and 12K unidirectional T800 series carbon fiber cloth with fiber tow. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: this embodiment is different from specific embodiment one or two: the carbon fiber cloth layer is a bidirectional T300 series carbon fiber cloth with fiber tows of 1K, 3K, 6K and 12K, and the fiber tows are 1K, 3K , 6K and 12K two-way T700 series carbon fiber cloth or fiber tows are 1K, 3K, 6K and 12K two-way T800 series carbon fiber cloth. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com