Preparation method of nanosheet phase reinforced tini-based alloy composite plate

A nanosheet and composite sheet technology, which is applied in the field of preparation of reinforced TiNi-based alloy composite sheets, can solve the problems of uneven distribution and size of the reinforced phase, difficulty in smelting nanosheet-based reinforced TiNi-based composite materials, etc., and meet equipment requirements Low, easy to control, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

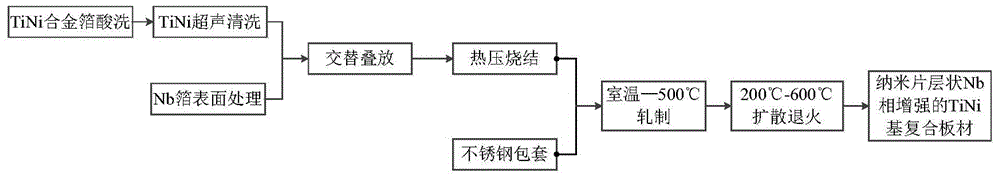

[0023] The preparation method of the nanosheet phase reinforced TiNi-based alloy composite plate of the present invention mainly comprises:

[0024] (1) According to the design requirements, the thickness of the TiNi-based shape memory alloy foil and the reinforced metal foil is selected, and the surface is pickled;

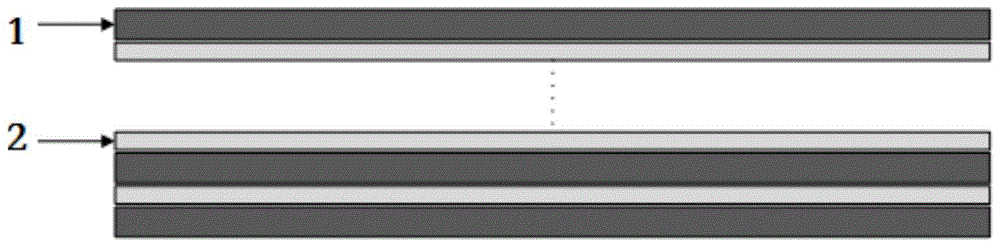

[0025] (2) alternately stack the pickled TiNi-based shape memory alloy and the reinforced metal foil and ensure that the outermost layer is a TiNi-based alloy foil, and use a sintering process to sinter it under a certain pressure and temperature;

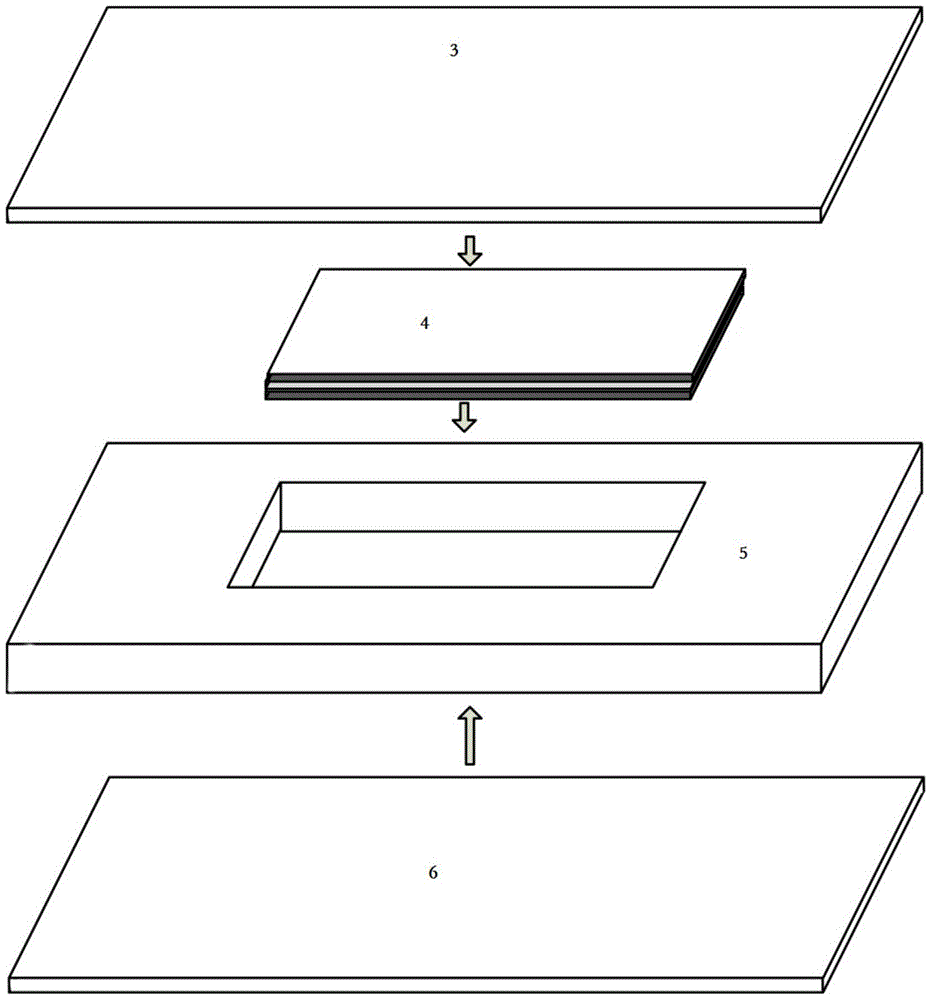

[0026] (3) Vacuum-seal the sintered TiNi-based alloy composite material in a stainless steel or pure Ti sheath, and repeatedly roll it to the required thickness at room temperature-500°C;

[0027] (4) Annealing the above-mentioned composite sheet in the range of 200° C. to 600° C. can obtain a nanosheet phase reinforced TiNi-based composite sheet.

[0028] The reinforcing phase metal elements include Nb, W and Ag, et...

specific Embodiment approach 1

[0031] (1) Put the TiNi shape memory alloy foil in HF, HNO 3 and pickling in a mixed solution of deionized water;

[0032] (2) Grinding the Nb foil with metallographic sandpaper to remove surface oxide skin;

[0033] (3) Place the pickled TiN shape memory alloy in acetone and ultrasonically clean it for 15 minutes, and rinse it with alcohol;

[0034] (4) Alternately stack pickled TiNi-based shape memory alloys and Nb foils and ensure that the outermost layer is a TiNi-based alloy sheet, which is sintered by hot-pressing sintering process, with a vacuum of 2×10 -3 -1×10 -2 Pa, the sintering pressure is 30-90MPa, the sintering temperature is 900-1100℃, and the sintering time is 0.5-4h;

[0035] (5) Vacuum-seal the sintered composite profile in a stainless steel sheath, and roll it into a plate at room temperature to 500°C, with a rolling deformation of 30% to 70%;

[0036] (6) Annealing the rolled composite plate at 200° C. to 600° C. for 1-2 hours to obtain a TiNi-based com...

specific Embodiment approach 2

[0038] The difference between this embodiment and Embodiment 1 is that the sintering method used in step (4) in this embodiment is spark plasma sintering, the sintering pressure is 30-90MPa, the sintering temperature is 850-1000°C, and the sintering time is 0.5-90MPa. 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com