A kind of preparation method of silicon carbide fiber bundle reinforced aluminum matrix composite material

A silicon carbide fiber and aluminum-based technology is applied in the field of inorganic composite materials, which can solve the problems of difficult addition of particles, cumbersome procedures, uneven distribution of composite materials, etc., so as to improve the mechanical bonding force, simplify the preparation steps, and reduce the preparation energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

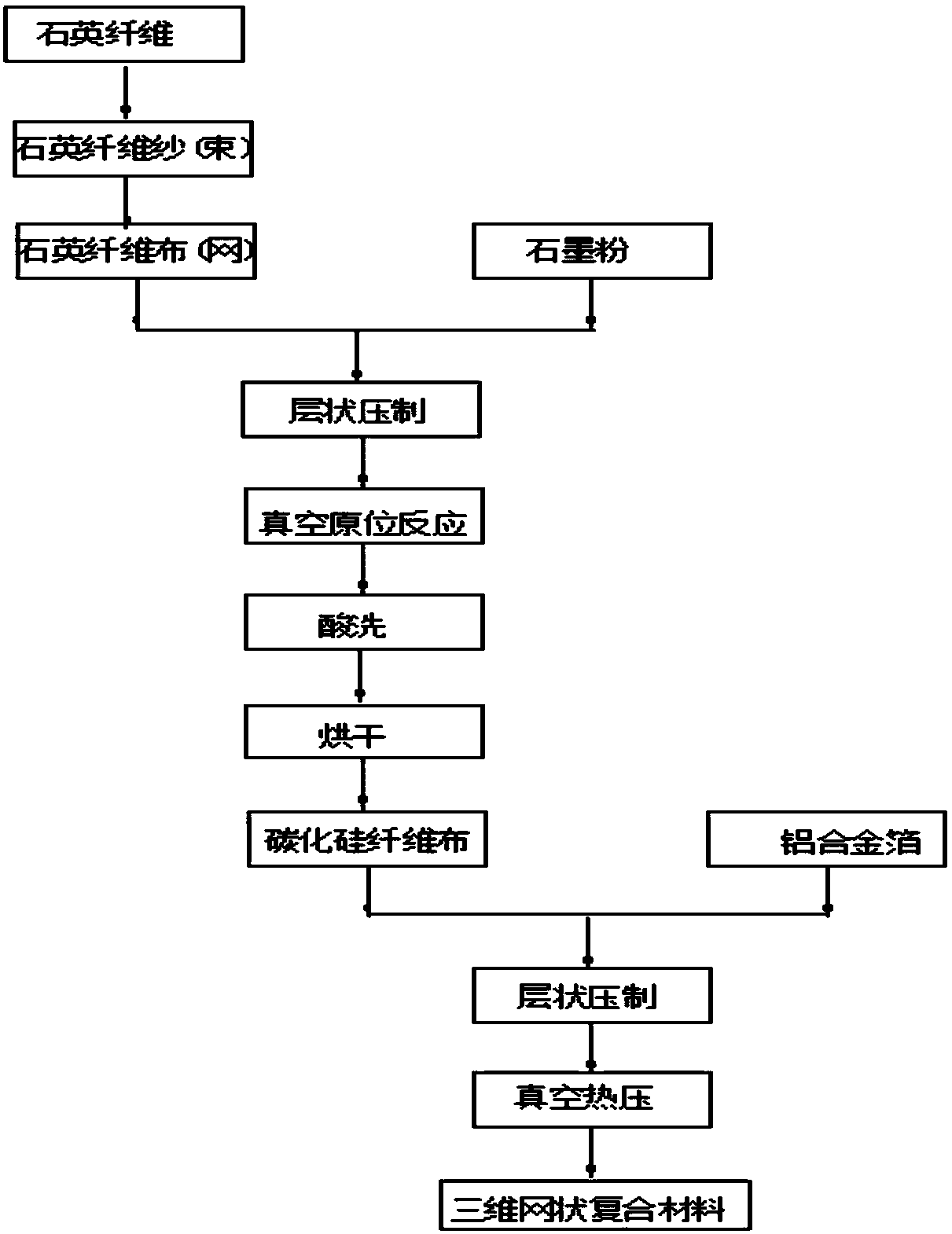

[0034] This embodiment provides a method for preparing a silicon carbide fiber bundle reinforced aluminum matrix composite material, comprising the following steps:

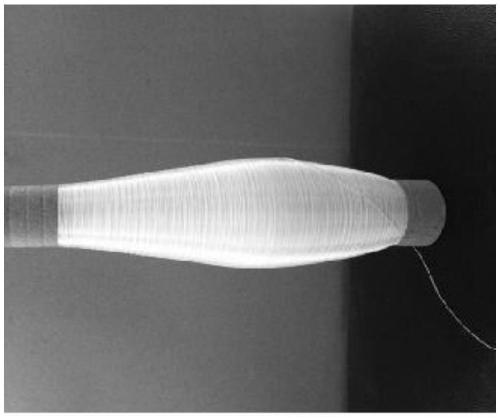

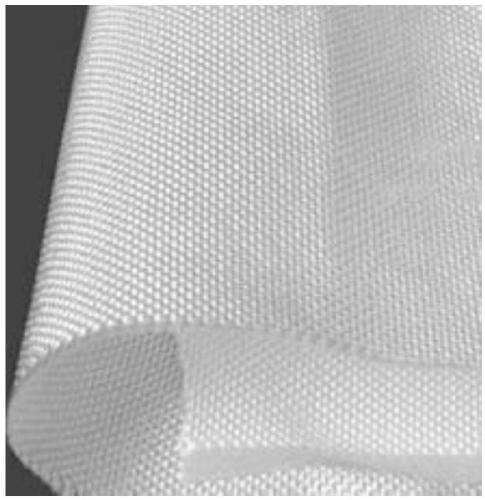

[0035] Step 1: Use a quartz fiber bundle of less than 1K ( figure 2 ) Woven into fiber cloth ( image 3 ), the diameter of the fiber is 5-7 microns, the porosity is about 30-35%, and the thickness is 0.12-0.13mm. The fiber cloth and graphite are pressed in layers, and put into a vacuum furnace, at 1250 ° C ± 10 ° C , carry out 2h in-situ reaction to obtain silicon carbide fiber cloth;

[0036] Step 2: Pickling the silicon carbide fiber cloth with hydrofluoric acid with a volume concentration of 5% to remove residual graphite to obtain a silicon carbide fiber cloth with a clean surface, which is cut into a mesh with an area of 100×100 mm, and a total of 50 pieces; cut a certain specification of 6061 aluminum alloy foil, the thickness of which is 0.15mm, and roughen the surface after sandblasting, 51 pieces in...

Embodiment 2

[0042] This embodiment provides a method for preparing an aluminum-matrix composite material reinforced with silicon carbide fiber bundles. The steps are the same as in Example 1, except that the specification of the fiber cloth in step 1 is 240 mesh, and 40 pieces of silicon carbide fiber cloth in step 2, 6010 The thickness of the aluminum alloy foil is 0.15 mm, and there are 41 pieces in total; Step 3: Press and sinter the preform at a temperature of 650±10° C., a pressure of 25 MPa, and a time of 1.5 hours.

[0043] The silicon carbide fiber bundle reinforced aluminum matrix composite material prepared in this example has a size of 50×50×10 mm, a volume fraction of silicon carbide fiber reinforcement of 60%, and a tensile strength of 200 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com