Preparation method and application of eggshell type molybdenum carbide catalyst

A molybdenum carbide, eggshell technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of simple operation, excellent performance and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 0.23g of ammonium paramolybdate into a beaker, measure 25ml of deionized water, and add 5 Al 2 o 3 pellets, let stand for 24 hours. Weigh 0.23g of melamine into another clean beaker, measure 25ml of deionized water, heat to 80°C, and keep the temperature of the solution at 80°C until the melamine is completely dissolved. Filter the soaked Al 2 o 3 The pellets were put into the melamine solution and reacted for 5 minutes. Filter to get Al 2 o 3 Rinse the pellets with deionized water, dry them, place them in an argon atmosphere, raise the temperature to 650°C at a heating rate of 5°C / min, keep the temperature for 90 minutes, and lower it to room temperature to obtain an eggshell-type molybdenum carbide catalyst.

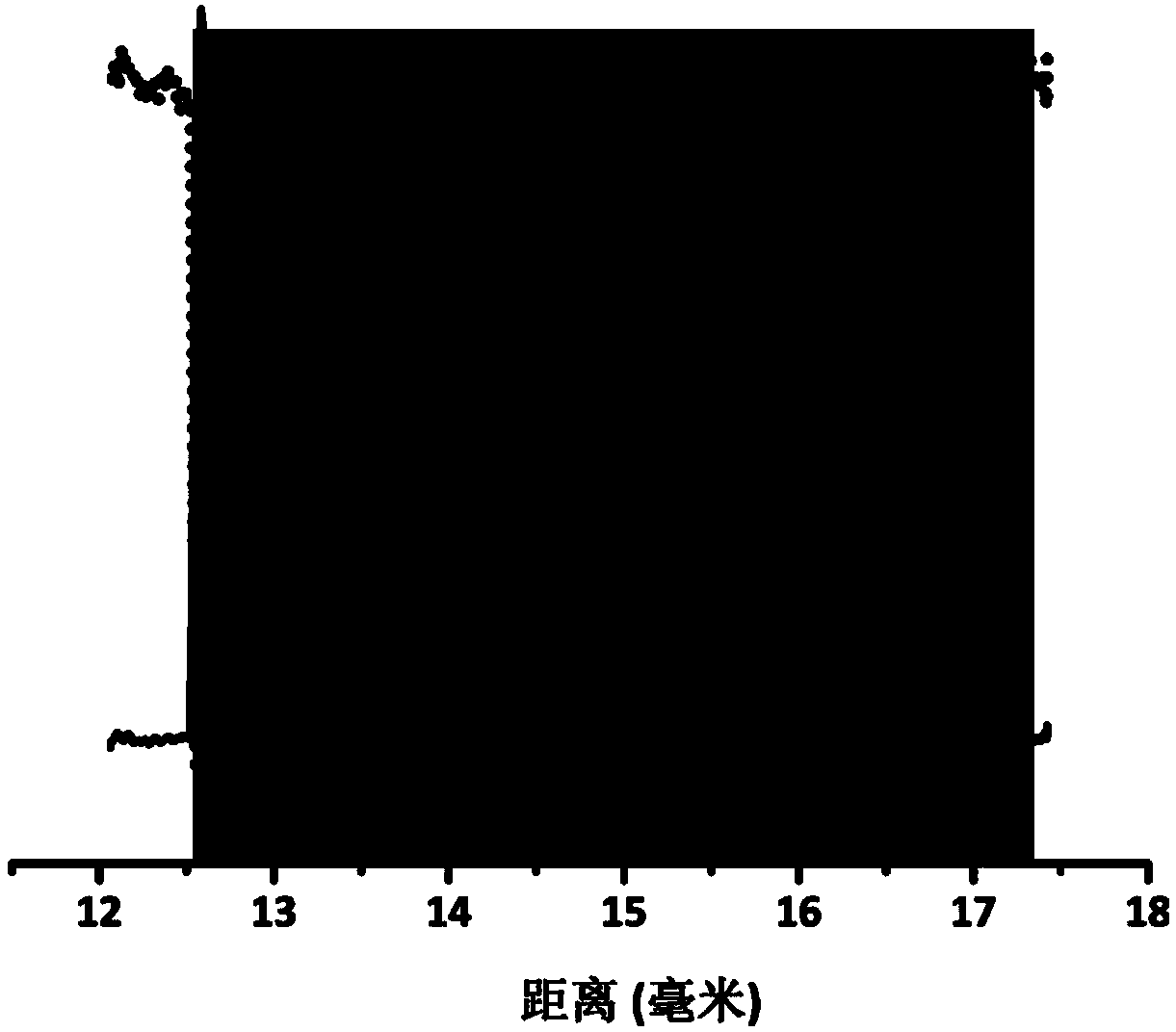

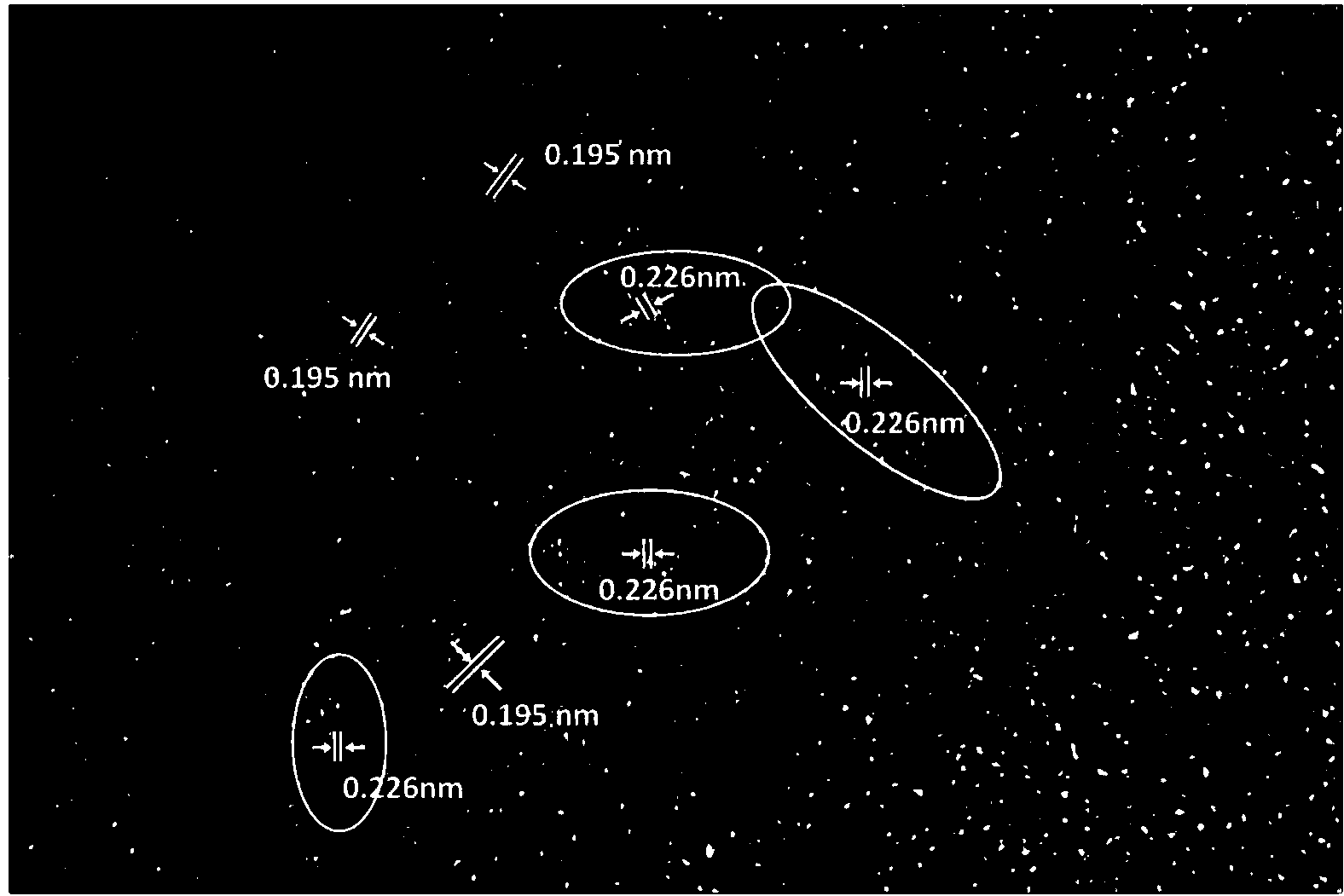

[0023] ICP results show that the mass percent content of metal Mo is 9.3%. The EPMA characterization result of gained eggshell molybdenum carbide catalyst is as follows figure 1 As shown, the transmission electron microscope pictures of molybdenum ...

Embodiment 2

[0025] Weigh 0.2g phosphomolybdic acid and put it into a beaker, and all the other steps are the same as in Example 1.

Embodiment 3

[0027] Weigh 0.2g silicomomolybdic acid and put it into a beaker, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com