MAX reinforced magnesium-based composite material and preparation method thereof

A composite material and alloy technology, applied in the field of cermet materials, can solve the problems of performance failure, limitation, and the performance of MAX reinforced magnesium matrix composite materials cannot meet the application requirements, and achieve the effect of dense structure, improved hardness and strength, and uniform composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

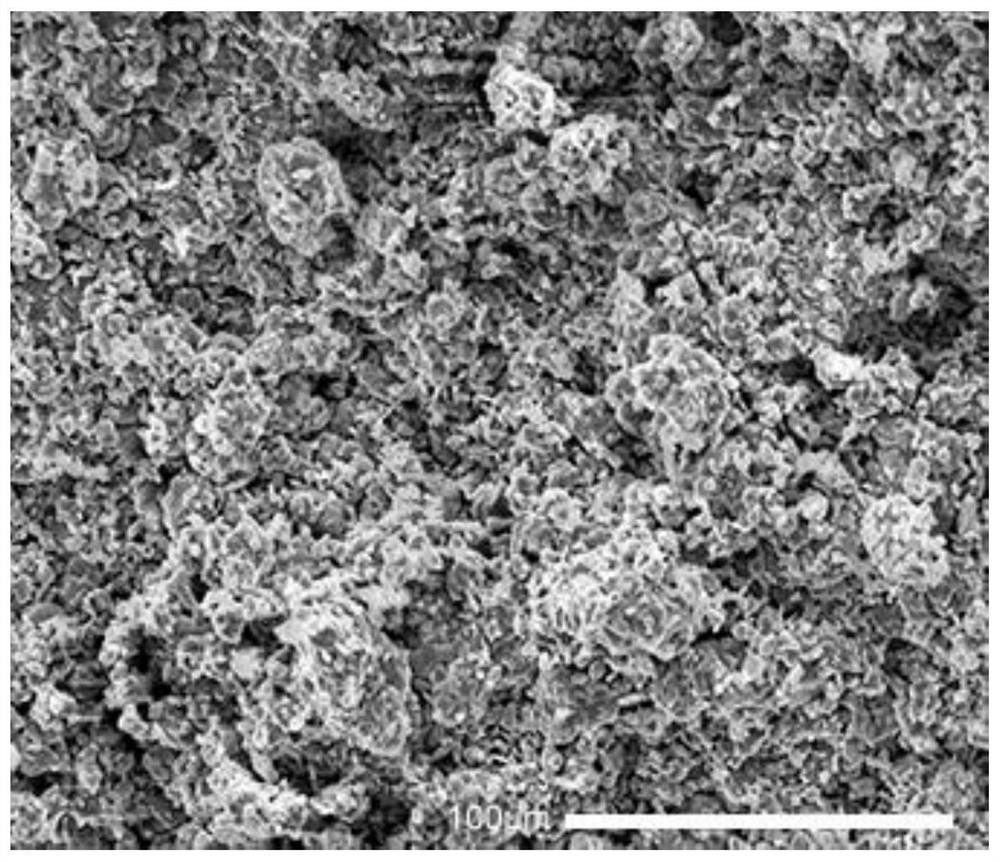

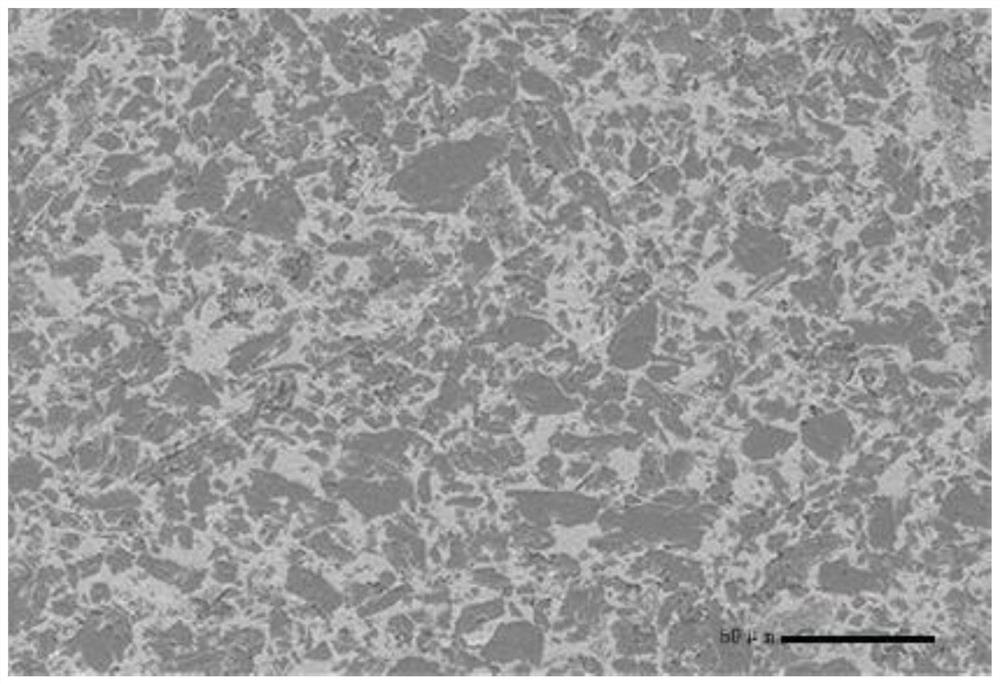

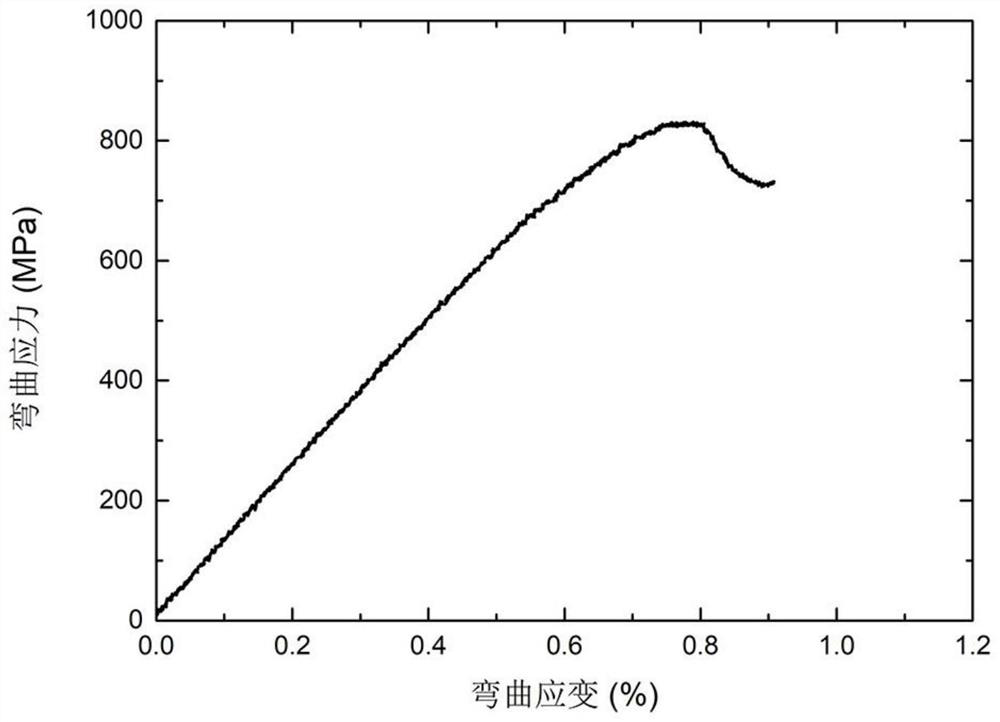

[0071] This embodiment provides a kind of MAX reinforced magnesium-based composite material, made of Ti 2 AlC or Ti 3 AlC 2 The metal ceramic phase of Mg or Mg alloy consists of a cermet phase and a metal phase of Mg or Mg alloy, and the cermet phase exists in the form of a three-dimensional porous framework in the MAX reinforced magnesium-based composite material. The specific performance is Ti 2 AlC or Ti 3 AlC 2 The cermet phase penetrates three-dimensionally, the metal phase and the ceramic phase are continuous, and the interface is well wetted, which can avoid the problem of performance failure and ensure stable performance.

[0072] Wherein, the porosity of the three-dimensional porous framework is 10%-70%, the diameter of the three-dimensional porous framework unit ring is 10nm-100μm, and the diameter of the metal phase of the Mg or Mg alloy is 10nm-100μm. The Ti 2 AlC or Ti 3 AlC 2 The volume fraction of the cermet phase is not less than 30%. In order to obtai...

Embodiment 2

[0075] This embodiment provides a method for making a MAX reinforced magnesium-based composite material, the method comprising:

[0076] Step 1, provide base powder, described base powder is Ti 2 AlC powder or Ti 3 AlC 2 powder;

[0077] Step 2, using the base powder to manufacture a three-dimensional porous framework;

[0078] Step 3, infiltrating the melted Mg or Mg alloy into the three-dimensional porous framework to form the MAX reinforced magnesium-based composite material.

[0079] Wherein, said step two includes:

[0080] Step S21 , making and forming a three-dimensional porous skeleton body by means of a compression molding process.

[0081] That is, placing the base powder in a compression mold;

[0082] Apply pressure to 3MPa-10MPa;

[0083] Keep the constant pressure for 0.1h-2h to form the three-dimensional porous skeleton green body.

[0084] In this embodiment, the Ti in the material 2 AlC or Ti 3 AlC 2 The volume fraction of will increase and decrease...

Embodiment 3

[0098] This embodiment provides a method for making a MAX reinforced magnesium-based composite material, the method comprising:

[0099] Step 1, provide 20g of base powder, the base powder is Ti 2 AlC powder.

[0100] Step 2, using the base powder to manufacture a three-dimensional porous framework. include:

[0101] Step S21 , making and forming a three-dimensional porous skeleton body by means of a compression molding process.

[0102] That is, the basic powder is evenly put into the mold;

[0103] Adjust the stroke of the hydraulic press to the fully open state, place the mold with the basic powder at the center of the hydraulic press, pressurize to 4MPa, keep the constant pressure for 0.2h to remove the pressure, and open the mold again to obtain a three-dimensional porous skeleton green body.

[0104] Step S22, sintering the green body to form the three-dimensional porous skeleton.

[0105]That is, the three-dimensional porous skeleton body was dried naturally at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com