A kind of Ni base alloy-graphene current collector and its preparation method and application

A graphene and current collector technology, applied in Ni-based alloy-graphene current collector and its preparation, in the field of current collector, can solve the problem of poor corrosion resistance of copper foil or aluminum foil and poor adhesion of positive and negative active materials , battery capacity reduction and other issues, to achieve the effect of improving electrochemical performance, avoiding performance failure, and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of Ni-based alloy-graphene current collector, and the preparation method comprises the following steps:

[0046] 1) uniformly dispersing nickel salt, boron salt, graphene and additives in a solvent to obtain a composite plating solution;

[0047] 2) The composite plating solution and current collector obtained in step 1) are coated or deposited with composite plating layers on both sides of the current collector by means of electroless plating or electrodeposition.

[0048] Optionally, nickel salt, boron salt, graphene and surfactant are respectively in weight percentage: nickel salt: 50-95%, boron salt: 2%-20%, graphene: 2%-20% and additive : 1%-20%.

[0049] Preferably, the additives are surfactants and pH adjusters;

[0050] The pH adjuster includes one of boric acid, sulfuric acid, sodium hydroxide, hydrochloric acid, nitric acid, and potassium hydroxide.

[0051] Most preferably, the additives are sodium d...

Embodiment 1

[0055] The present embodiment provides a specific preparation method of Ni-based alloy-graphene current collector, including:

[0056] 1. Weigh 100g of nickel sulfate, 5g of trimethylamine borane, 0.5g of sodium dodecylbenzenesulfonate, 4g of graphene, and 25g of boric acid, stir evenly at room temperature, and prepare 500mL of electrodeposition solution with deionized water. The pH was adjusted to 4.3 with sodium hydroxide and dilute sulfuric acid, and the Ni-based alloy-graphene electrodeposition solution was prepared by mechanical stirring in a water bath for 12 h at a temperature of 45 °C;

[0057] 2. Put the prepared electrodeposition solution in the electrodeposition tank, use the nickel plate as the anode and the copper foil as the cathode, the current density is 1.5A / dm2, the temperature is 45℃, and the time is 120s. A copper foil current collector rich in Ni-based alloy-graphene composite coating was prepared.

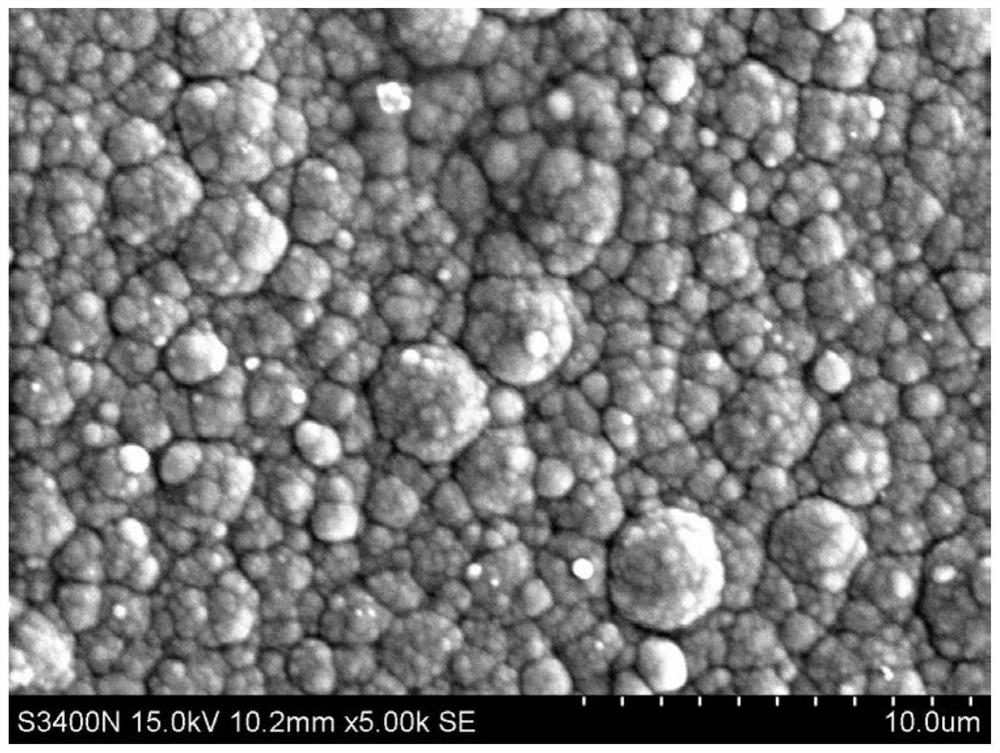

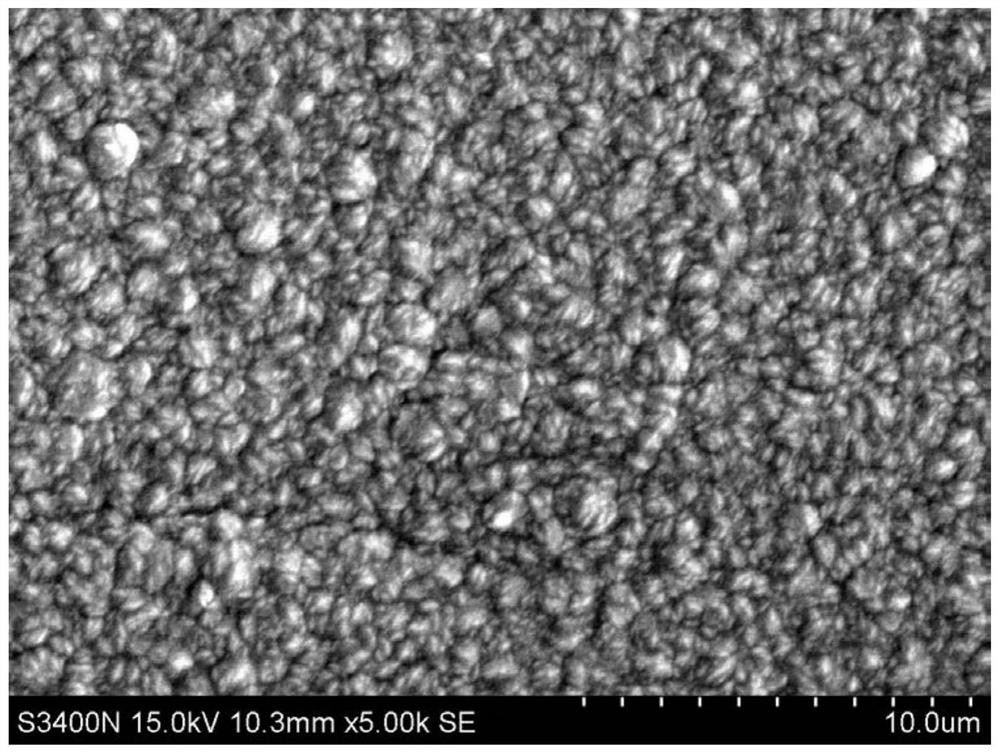

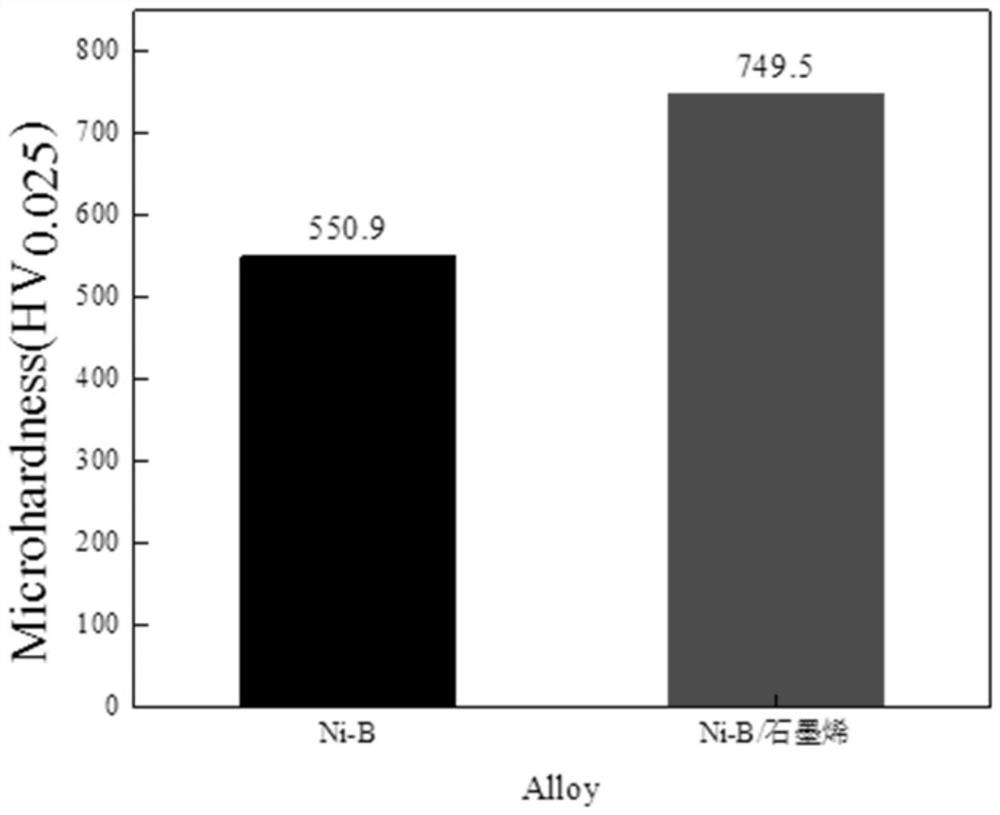

[0058] 3. The morphology of the prepared Ni-based alloy...

Embodiment 2

[0060] The present embodiment provides a specific preparation method of Ni-based alloy-graphene current collector, including:

[0061] 1. Weigh 50g of nickel sulfate, 20g of sodium borohydride, 0.4g of sodium dodecylbenzenesulfonate, 20g of graphene, and 19.6g of boric acid, stir evenly at room temperature, and prepare 500mL of electrodeposition solution with deionized water. Use sodium hydroxide and dilute sulfuric acid to adjust the pH to 4.2, mechanically stir in a water bath for 12 hours, and at a temperature of 45 °C to prepare a Ni-based alloy-graphene electrodeposition solution;

[0062] 2. Put the prepared electrodeposition solution in the electrodeposition tank, use the nickel plate as the anode, the copper foil as the cathode, and the current density is 1A / dm 2 , temperature 10 ℃, time 1000s. A copper foil current collector rich in Ni-based alloy-graphene composite coating was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com