A kind of preparation method of porous metal/nano-carbon phase composite material with multilayer structure

A technology for porous metal and composite materials, which is applied in the field of preparation of porous metal/nano-carbon phase composite materials, can solve the problems of non-wetting, inability to disperse uniformly, and inability to synthesize composite materials, and achieves strong interface bonding and simplified process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

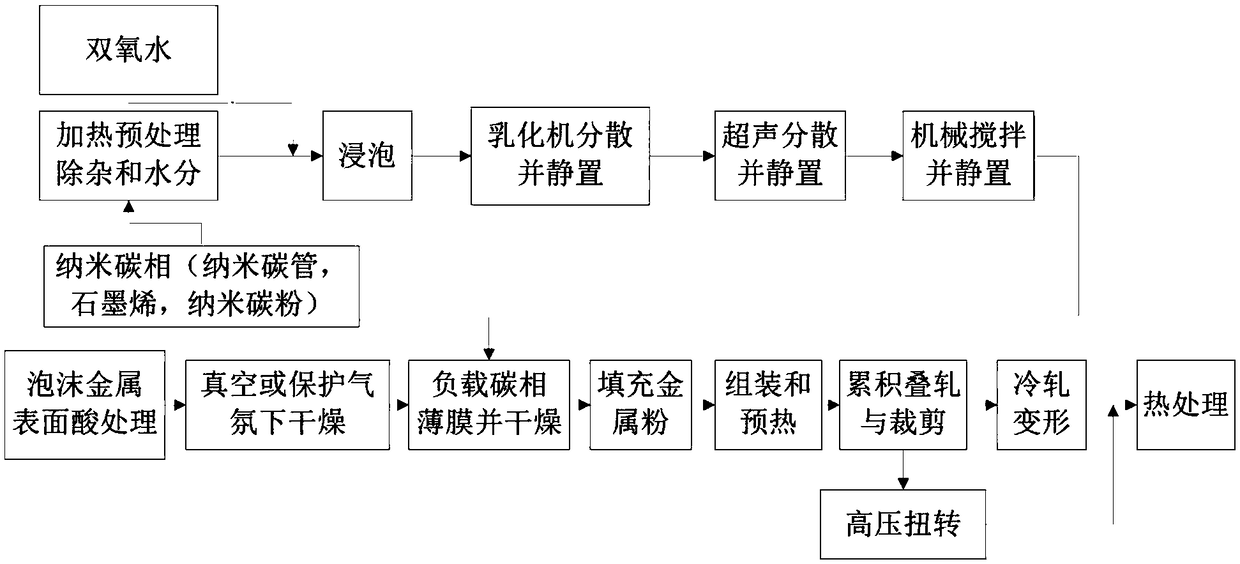

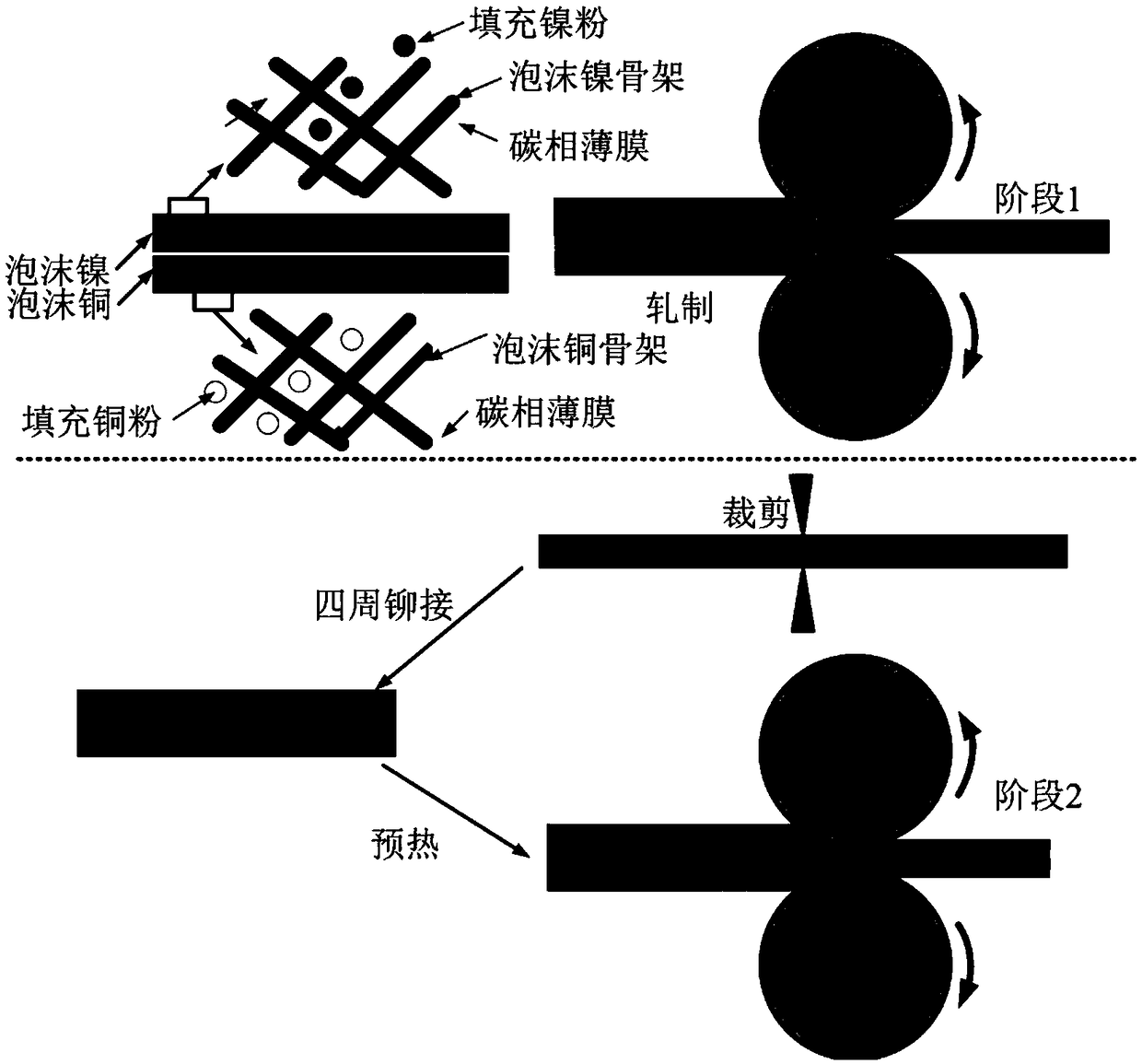

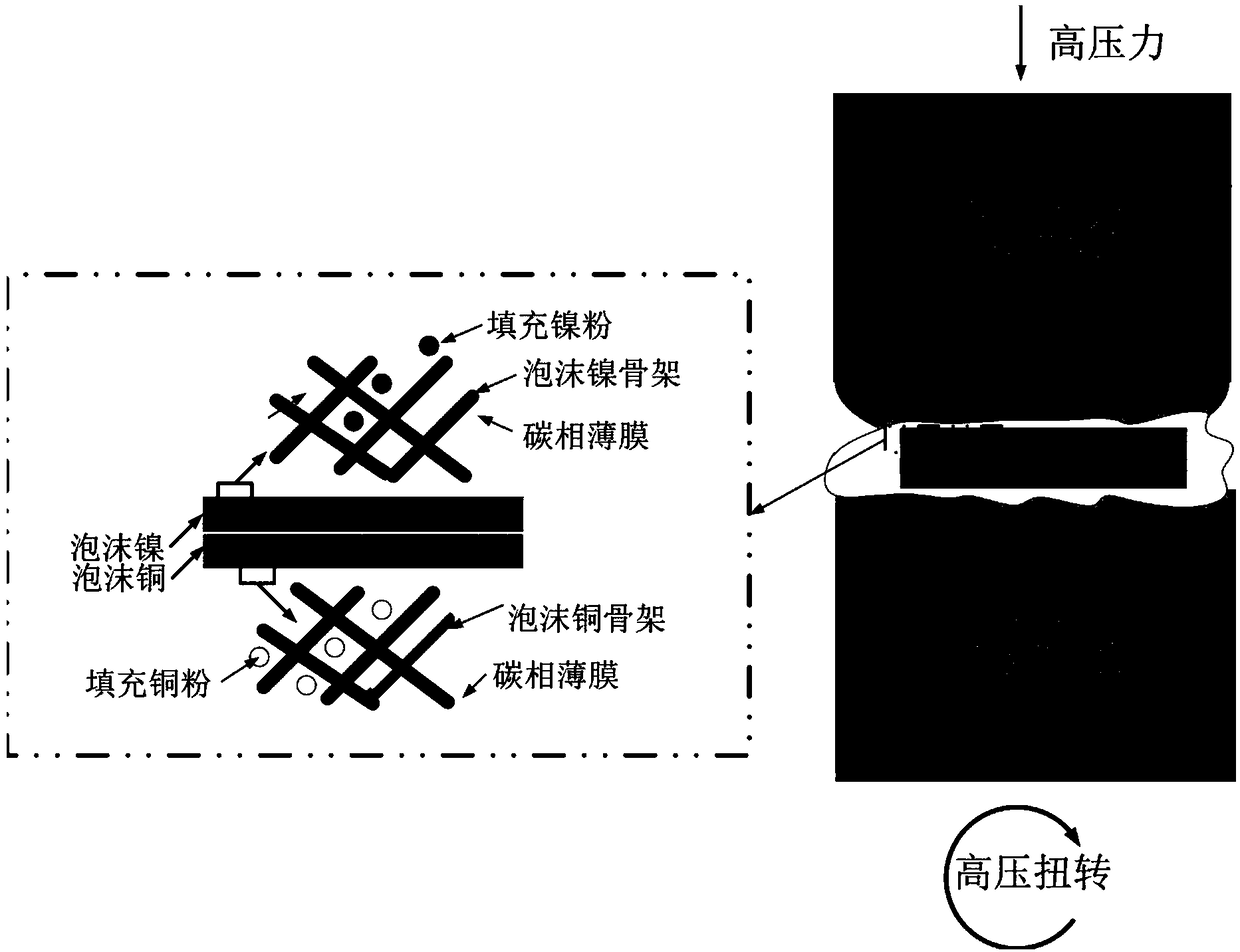

Method used

Image

Examples

Embodiment 1

[0041] (1) Carbon nanotube pretreatment

[0042] Select carbon nanotubes with an average diameter of 30-80 nm and a length of 5-15 µm as raw materials for pretreatment, that is, carbon nanotubes are heated to 180 °C and kept for 5 hours to remove some impurities and water.

[0043] (2) Preparation of carbon nanotube dispersion:

[0044] Put 1.5 g of carbon nanotubes pretreated in step (1) into 300 ml of hydrogen peroxide solution with a concentration of 6% by mass, and soak for 5 hours; The speed is 4000 rev / min, cooled to room temperature, and after standing still for 20 hours, the carbon nanotube mixture was treated with an ultrasonic cleaner for 30 minutes at a frequency of 45kHZ, cooled to room temperature, and after standing still for 20 hours, the carbon nanotube mixture was Mechanical mixer 1500 rev / min process 1 hour, cool to room temperature, obtain carbon nanotube dispersion liquid after standing still for 20 hours, see Figure 4 .

[0045] (3) Porous metal surfac...

Embodiment 2

[0062] (1) Graphene pretreatment:

[0063] Graphene with a lateral size of 30-80 µm and a vertical size of 20-50 nm was selected as the raw material for pretreatment, that is, the graphene was heated to 200 °C and kept for 5 hours to remove some impurities and moisture.

[0064] (2) Preparation of graphene dispersion:

[0065] Put 1g of graphene into the mixture of 0.06g of surfactant SDBS (sodium dodecylbenzenesulfonate) and 0.2g of analytically pure Tween-80, and soak for 5 hours to obtain the graphene mixture; the graphene mixture Dispersed by a dispersing emulsifier for 30 minutes, with a rotation speed of 4000 rpm, cooled to room temperature, and left standing still for 20 hours, the graphene mixture was treated by an ultrasonic cleaner for 30 minutes, with a frequency of 50 kHz, cooled to room temperature, and kept standing still for 20 hours Afterwards, the graphene mixture was processed by a mechanical stirrer at 1500 rpm for 1 hour, cooled to room temperature, and le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com