Method for preparing fcc-Al reinforced amorphous/aluminum laminar composite material on basis of accumulative roll bonding

A layered composite material, fcc-al technology, applied in the direction of metal rolling, can solve the problem of limited size, etc., to achieve the effect of improved mechanical properties and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

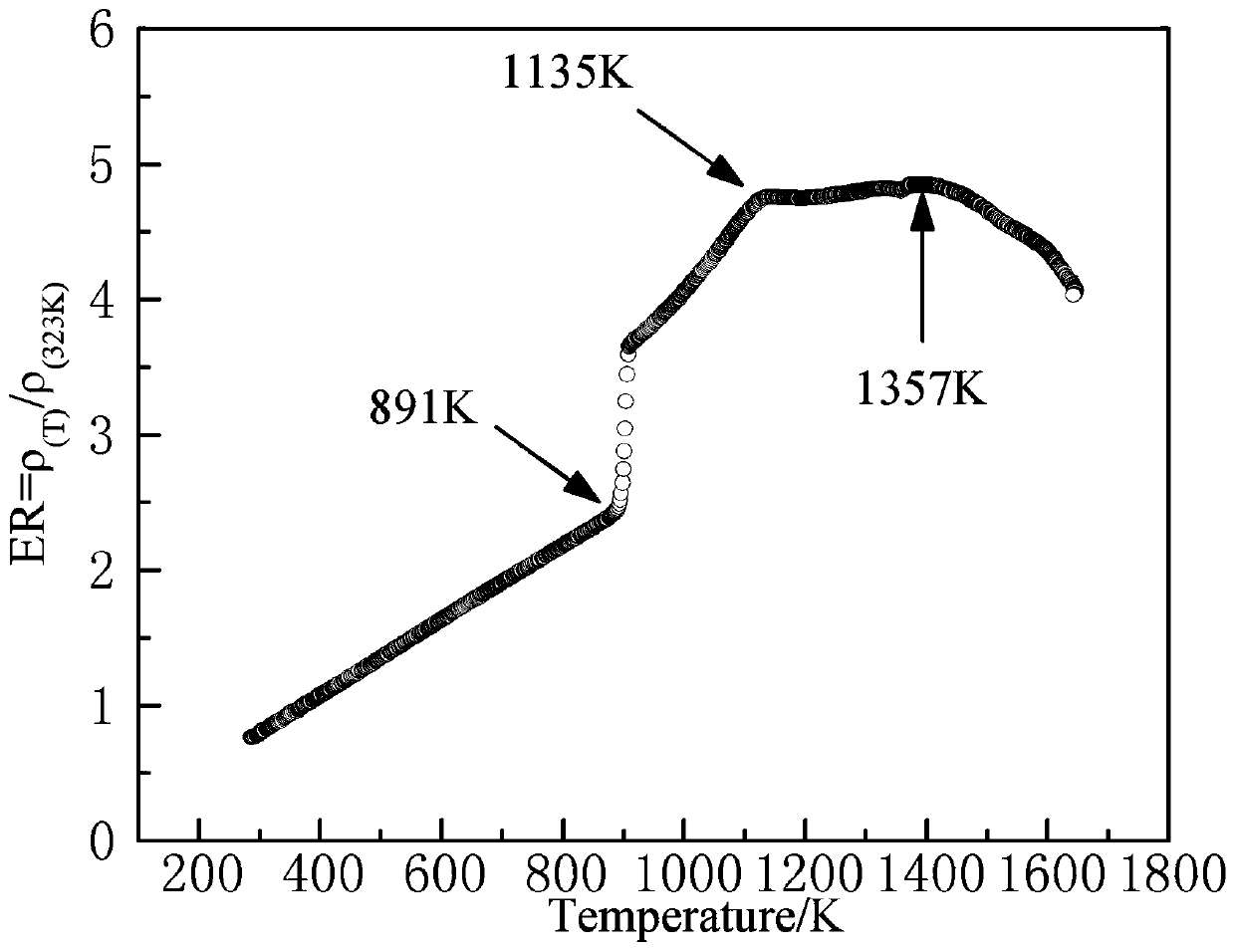

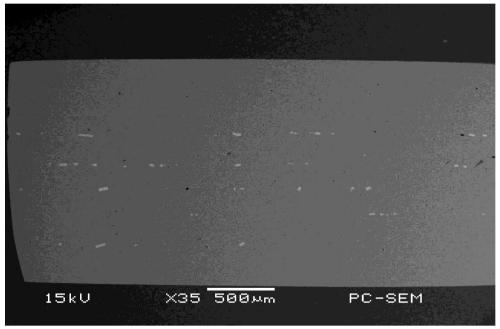

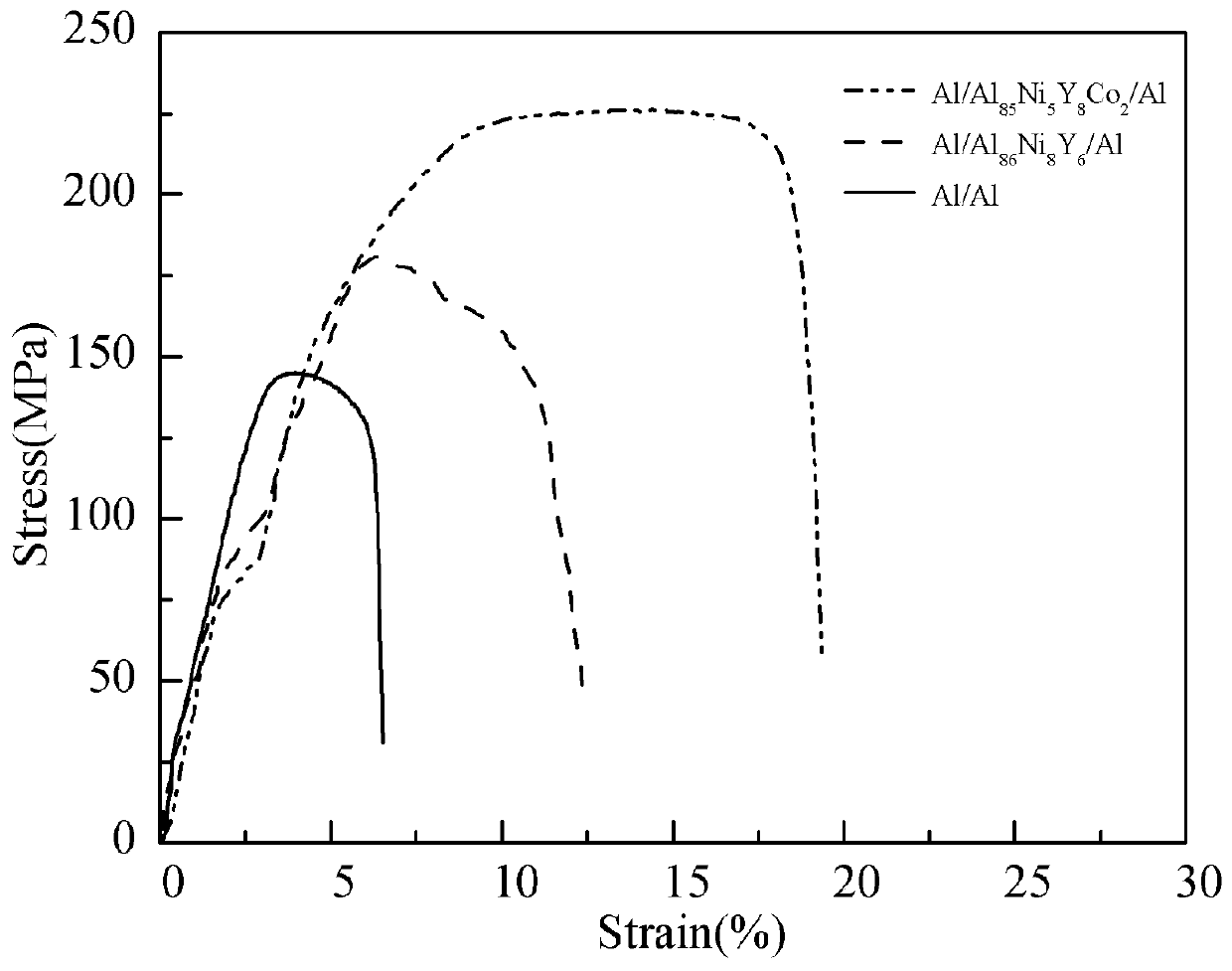

[0025] 1. Al, Ni, Y, Co metal according to Al 85 Ni 5 Y 8 co 2 The stoichiometric ratio is weighed, placed in a vacuum electric arc furnace for repeated melting 4 times, the master alloy ingot is smashed, part of it is placed in a quartz porcelain boat, graphite four electrodes are placed at a certain distance, and a tungsten wire is used to lead out and a constant current source As well as the nanovoltmeter connection, the K-type thermocouple is used to calibrate the temperature. The above-mentioned electrodes and thermocouples are separated by porcelain sleeves to prevent the connection short circuit from affecting the current. Then put the bound sample in a vacuum tube resistance furnace, and vacuumize to 8×10 -2 Pa, after filling with argon, raise the furnace temperature to 1573K at a heating rate of 5K / min and keep it for 30min, so that the metal melts and fills the bottom of the porcelain boat, solidifies into a certain shape, and then cools down to room temperature w...

Embodiment 2

[0030] Method is with embodiment 1, and difference is:

[0031] 1. The composition of amorphous alloy is Al 86 Ni 8 Y 6 Alloy, its melt structure transformation range is 1121K-1387K.

[0032] 2. Select the melt temperature to be 1600K to prepare amorphous thin strips.

[0033] 3. The heating temperature selected when rolling with 1060Al plate is 280°C, and the cumulative rolling is accumulated after preheating for 5 minutes. The hardness of the layered material is 48.5HV, the tensile strength is 155MPa, and the elongation is 12.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com