TiAl3 particle reinforced aluminum matrix composite material and preparation method and application thereof

A particle-reinforced aluminum and composite material technology, applied in the field of composite material preparation, can solve the problems of poor tensile properties, coarse particles, uneven distribution, etc., and achieve the effect of excellent performance, simple method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

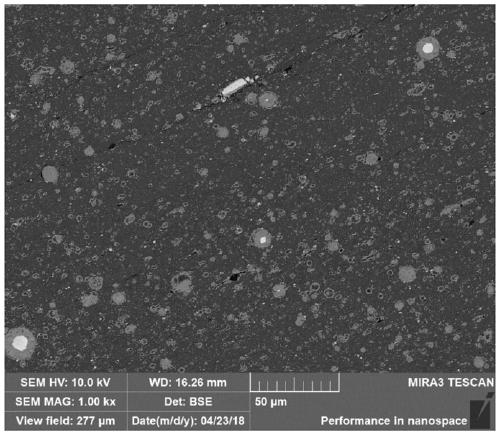

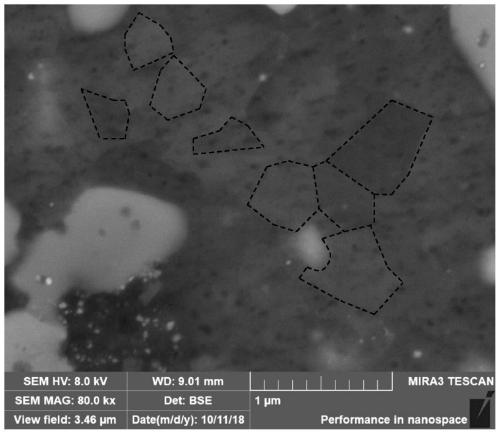

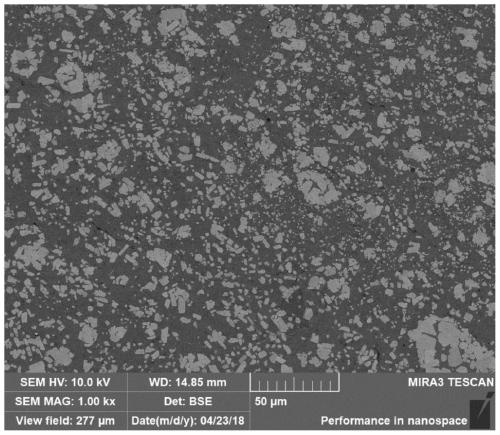

Image

Examples

Embodiment 1

[0044] The purity of the aluminum sheet in this embodiment is 99.99%, and the dimensions are: length 125mm, width 25mm, thickness 0.25mm. The average particle size of nano titanium powder is 40nm. Adopt industrial rolling mill, rolling speed is 187mm / min.

[0045] (1) First, 8 pieces of pure aluminum sheets with a size of 125×25×0.25 mm were cut out, and the surfaces were polished and cleaned. Use an analytical balance to weigh the total weight of 8 pure aluminum sheets, after calculation, weigh 10% of the total weight of the 8 pure aluminum sheets to weigh the nano-titanium powder, add the weighed nano-titanium powder to an appropriate amount of ethanol, and use ultrasonic cleaning The instrument makes the nano-titanium powder uniformly mixed in ethanol to obtain the nano-titanium powder-ethanol suspension.

[0046] (2) Pour the nano-titanium powder-ethanol suspension evenly on the surface of 7 pure aluminum sheets, after the ethanol is completely volatilized, keep the 7 pu...

Embodiment 2

[0055] The purity of the aluminum sheet in this embodiment is 99.99%, and the dimensions are: length 125mm, width 25mm, thickness 0.25mm. The average particle size of nano titanium powder is 40nm. Adopt industrial rolling mill, rolling speed is 187mm / min.

[0056] (1) First, 8 pieces of pure aluminum sheets with a size of 125×25×0.25 mm were cut out, and the surfaces were polished and cleaned. Use an analytical balance to weigh the total weight of 8 pure aluminum sheets, after calculation, weigh 10% of the total weight of the 8 pure aluminum sheets to weigh the nano-titanium powder, add the weighed nano-titanium powder to an appropriate amount of ethanol, and use ultrasonic cleaning The instrument makes the nano-titanium powder uniformly mixed in ethanol to obtain the nano-titanium powder-ethanol suspension.

[0057] (2) Pour the nano-titanium powder-ethanol suspension evenly on the surface of 7 pure aluminum sheets, after the ethanol is completely volatilized, keep the 7 pu...

Embodiment 3

[0068] The purity of the aluminum sheet in this embodiment is 99.99%, and the dimensions are: length 125mm, width 25mm, thickness 0.25mm. The average particle size of nano titanium powder is 40nm. Adopt industrial rolling mill, rolling speed is 187mm / min.

[0069] (1) First, 8 pieces of pure aluminum sheets with a size of 125×25×0.25 mm were cut out, and the surfaces were polished and cleaned. Use an analytical balance to weigh the total weight of 8 pure aluminum sheets, after calculation, weigh 10% of the total weight of the 8 pure aluminum sheets to weigh the nano-titanium powder, add the weighed nano-titanium powder to an appropriate amount of ethanol, and use ultrasonic cleaning The instrument makes the nano-titanium powder uniformly mixed in ethanol to obtain the nano-titanium powder-ethanol suspension.

[0070] (2) Pour the nano-titanium powder-ethanol suspension evenly on the surface of 7 pure aluminum sheets, after the ethanol is completely volatilized, keep the 7 pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com