Preparation method for TLM titanium alloy foil with nanocrystalline structure

A titanium alloy foil and nanocrystalline technology, which is used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problem of inability to roll high-precision, high-finish titanium alloy foils, and achieve small limitations in sheet size and material. , easy to control, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the TLM titanium alloy foil with nanocrystalline structure in this embodiment comprises the following steps:

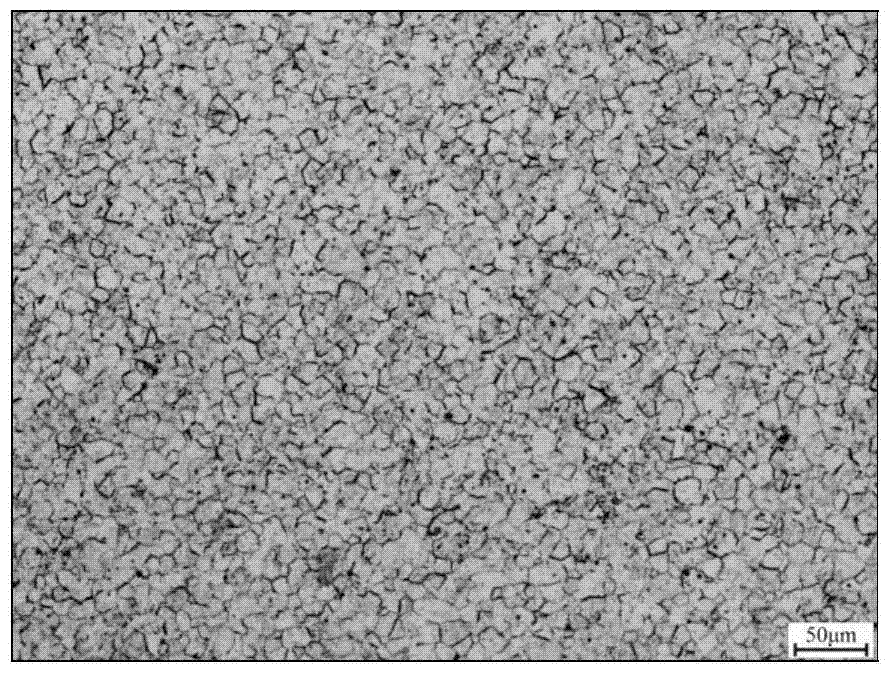

[0035] Step 1. Perform uniform annealing treatment on the TLM titanium alloy plate. The specific process of the homogenization annealing treatment is: place the TLM titanium alloy plate in a vacuum annealing furnace, and keep it warm for 30 minutes at a temperature of 1023K; the TLM The thickness of the titanium alloy plate is 1 mm, and the average grain size is 20 μm (the photo of its metallographic microstructure is as follows figure 1 shown);

[0036] Step 2. Surface treatment is carried out on the TLM titanium alloy plate after the uniform annealing treatment in step 1. The specific process is: first, ultrasonically clean the TLM titanium alloy plate, and then use sandblasting to remove the oxide layer on the surface of the plate and remove the surface of the plate. The surface is roughened, then pickled, rinsed with running water...

Embodiment 2

[0046] The preparation method of the TLM titanium alloy foil with nanocrystalline structure in this embodiment comprises the following steps:

[0047] Step 1. Perform uniform annealing treatment on the TLM titanium alloy plate. The specific process of the homogenization annealing treatment is: place the TLM titanium alloy plate in a vacuum annealing furnace, and keep it warm for 30 minutes at a temperature of 1023K; the TLM The thickness of the titanium alloy plate is 2mm, and the average grain size is 100μm;

[0048] Step 2. Surface treatment is carried out on the TLM titanium alloy plate after the uniform annealing treatment in step 1. The specific process is: first, ultrasonically clean the TLM titanium alloy plate, and then use sandblasting to remove the oxide layer on the surface of the plate and remove the surface of the plate. The surface is roughened, then pickled, rinsed with running water and then dried; the sand particle size of the sandblasting is 80 mesh, and the ...

Embodiment 3

[0056] The preparation method of the TLM titanium alloy foil with nanocrystalline structure in this embodiment comprises the following steps:

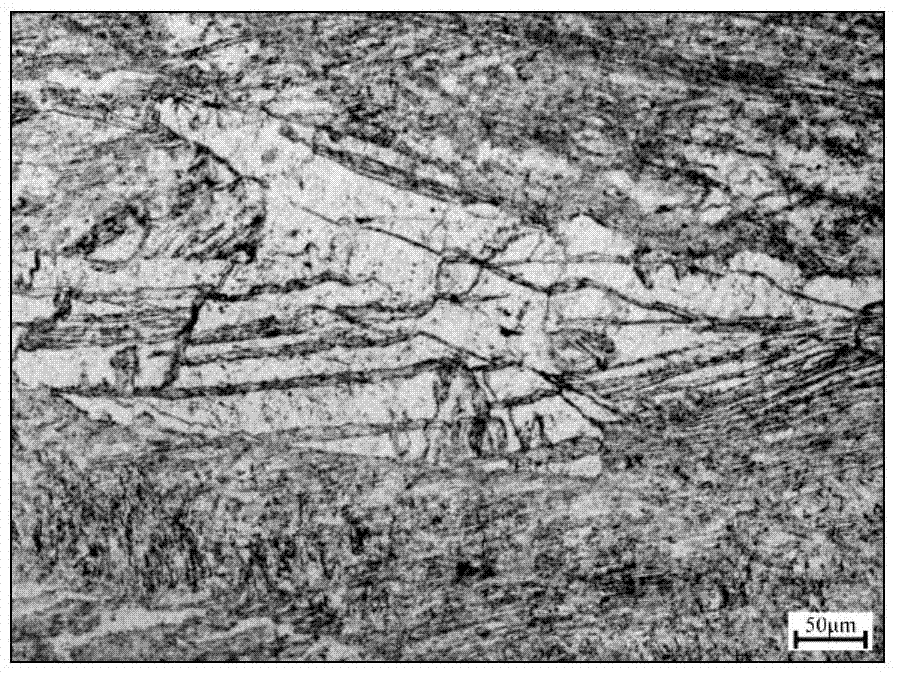

[0057] Step 1. Perform uniform annealing treatment on the TLM titanium alloy plate. The specific process of the homogenization annealing treatment is: place the TLM titanium alloy plate in a vacuum annealing furnace, and keep it warm for 20 minutes at a temperature of 923K; the TLM The thickness of the titanium alloy plate is 0.7mm, and the average grain size is 100μm (its metallographic microstructure is as follows Figure 5 shown);

[0058] Step 2. Surface treatment is carried out on the TLM titanium alloy plate after the uniform annealing treatment in step 1. The specific process is: first, ultrasonically clean the TLM titanium alloy plate, and then use sandblasting to remove the oxide layer on the surface of the plate and remove the surface of the plate. The surface is roughened, then pickled, rinsed with running water and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com