Metal damper with rolling shafts

A technology of metal dampers and rollers, which is applied to bridge parts, building components, bridges, etc., can solve the problems of small rigidity and large deformation, and achieve the effect of small rigidity, strong deformation ability and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

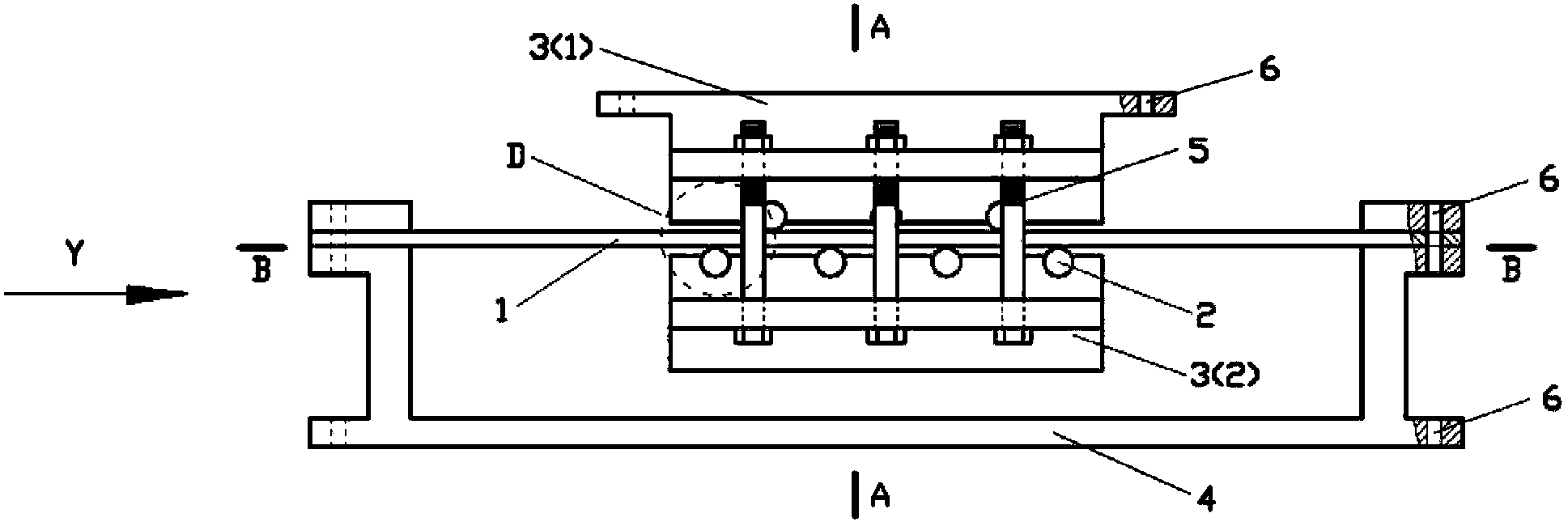

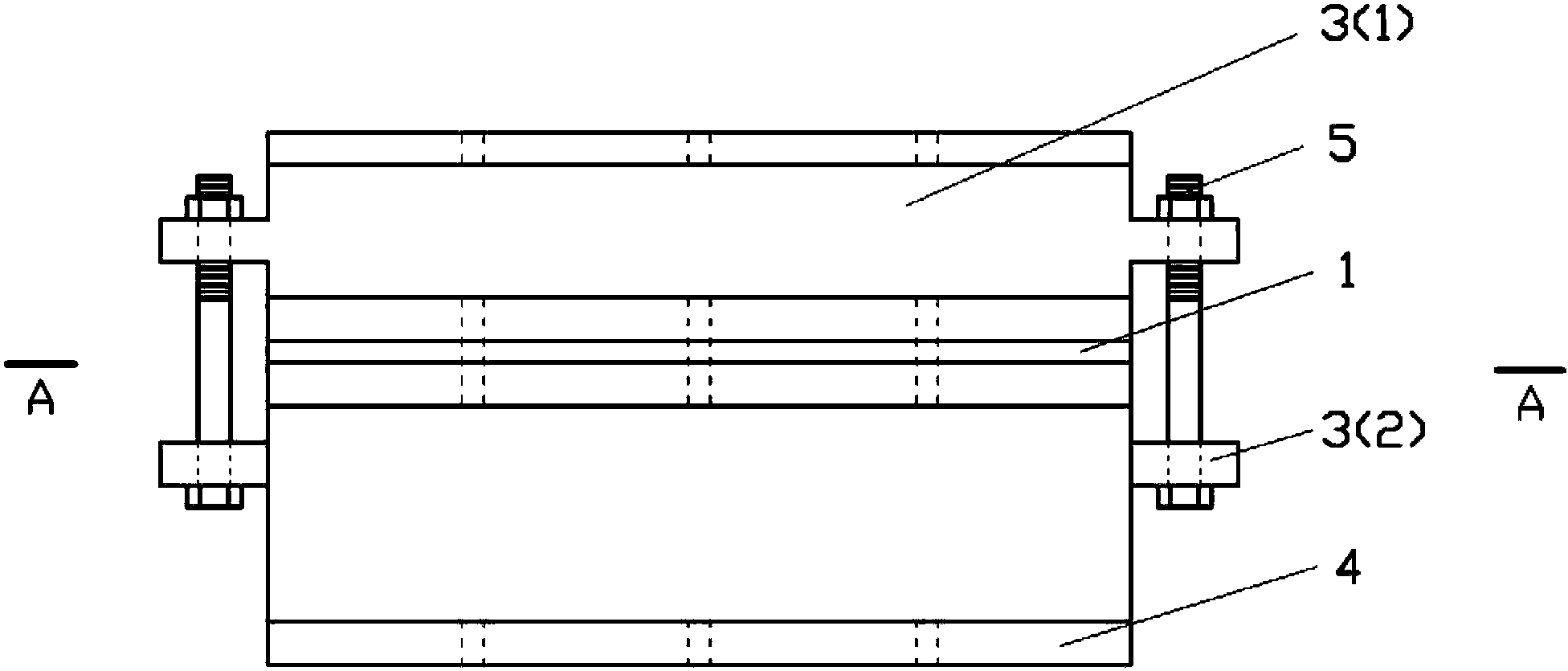

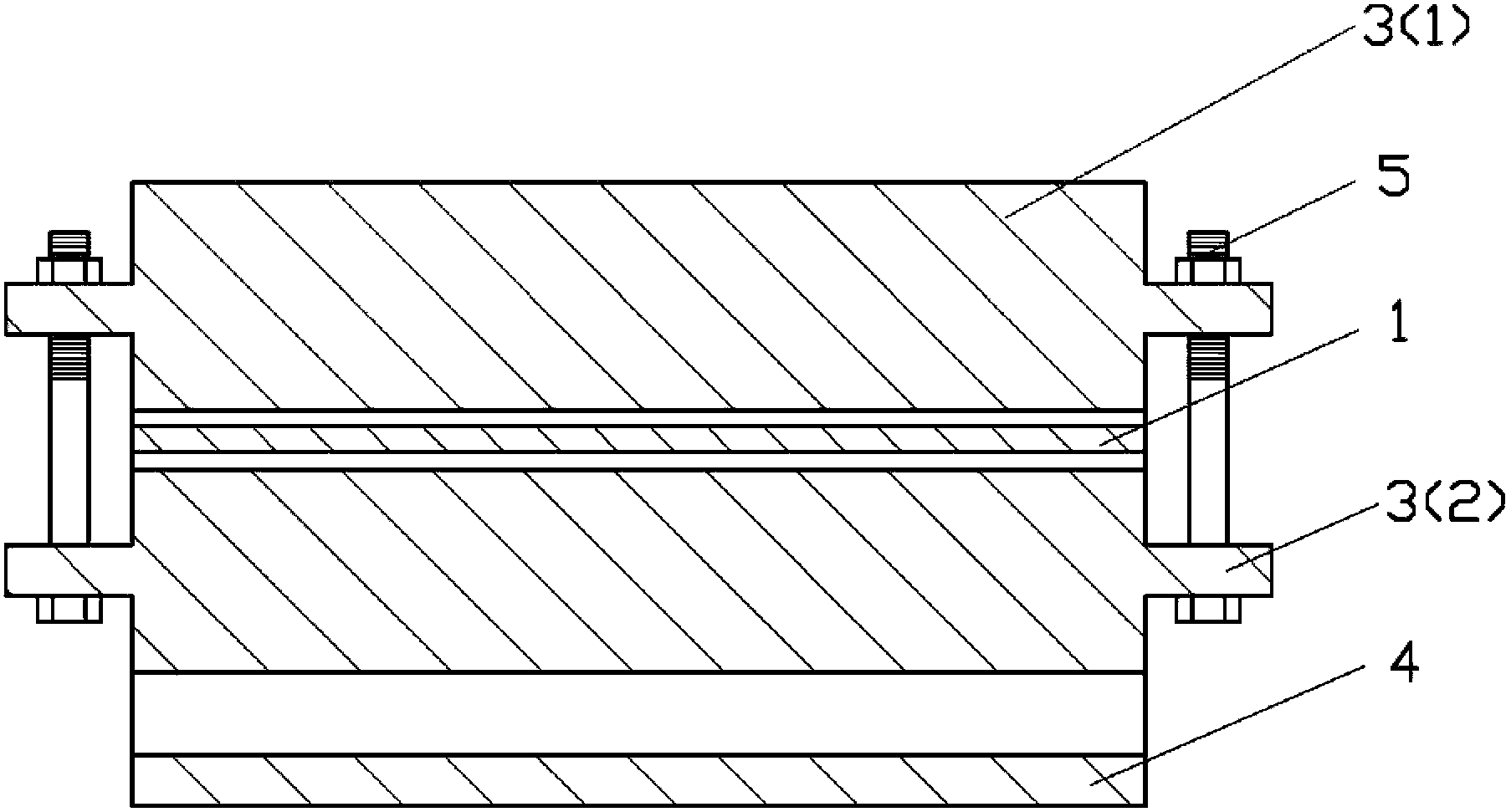

[0040] Such as figure 1 , figure 2 The roller metal damper of the present invention shown includes a metal plate 1 and a roller 2, as well as a roller support 3 and a metal plate support 4.

[0041] Both ends of the metal plate 1 are fixedly connected to the building structure through the bolt through holes 6 on the metal plate support 4, and the length direction of the metal plate 1 is consistent with the direction in which the building structure bears the shearing force. The roller 2 is made of steel with a smooth surface, and is placed in a cylindrical groove in the roller support 3. The roller support 3 is divided into two upper and lower parts (3(1) and 3(2)), and the roller 2 and the metal plate 1 between the roller 2 and the metal plate 1 are pressed by the action of the bolt 5. The rollers 2 are arranged at equal intervals along the length direction of the metal plate 1 on the upper and lower sides of the metal plate 1, and the vertical positions of the rollers 2 on the ...

Embodiment 2

[0046] Such as Figure 5 , Image 6 As shown, when the horizontal shear force received by the building structure is large, multiple metal plates 1 can be arranged in parallel in a single damper, and the length direction of the metal plates 1 is consistent with the horizontal anti-lateral force direction. Correspondingly, the roller 2 is also arranged in multiple layers. In addition to the top roller support 3(1) and the bottom roller support 3(2), the roller support 3 is provided with several middle layers 3(3), and the top roller The support 3(1), the bottom roller support 3(2) and the middle layer 3(3) are fastened by bolts 5. By controlling the tightness of the bolt 5, different degrees of pressure between the rollers 2 and the metal plate 1 are realized, that is, different degrees of damping values of the damper are realized.

[0047] When the building structure requires horizontal shock absorption and energy consumption in both directions, the length directions of the meta...

Embodiment 3

[0050] Based on the technical principles described in the first and second embodiments, the roller metal damper of the present invention has a compact and concise structure, and its design features can ensure its large deformation, so the overall size of the present invention can be controlled to be small.

[0051] Such as Picture 10 As shown, the difference from the first and second embodiments is that when the structure space of the present invention is large, an auxiliary bracket 7 can be added to the steel frame 8 to connect the upper part of the roller support 3 to The metal plate support 4 is connected with the auxiliary bracket 7 to fix the present invention on the steel frame 8. Of course, the present invention can also be turned upside down so that the metal plate support 4 is connected to the steel frame 8, and the roller support 3 is connected to the auxiliary support 7. The specific installation method depends on the engineering situation and the convenience of constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com