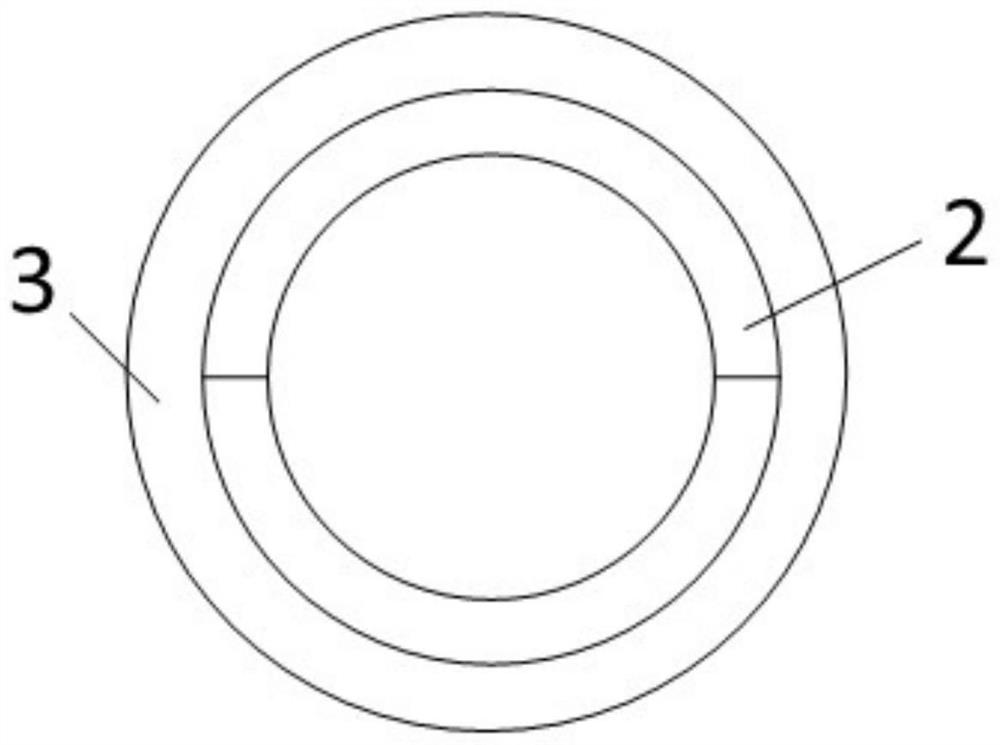

Superplastic forward and reverse bidirectional variable-temperature extrusion forming method and application

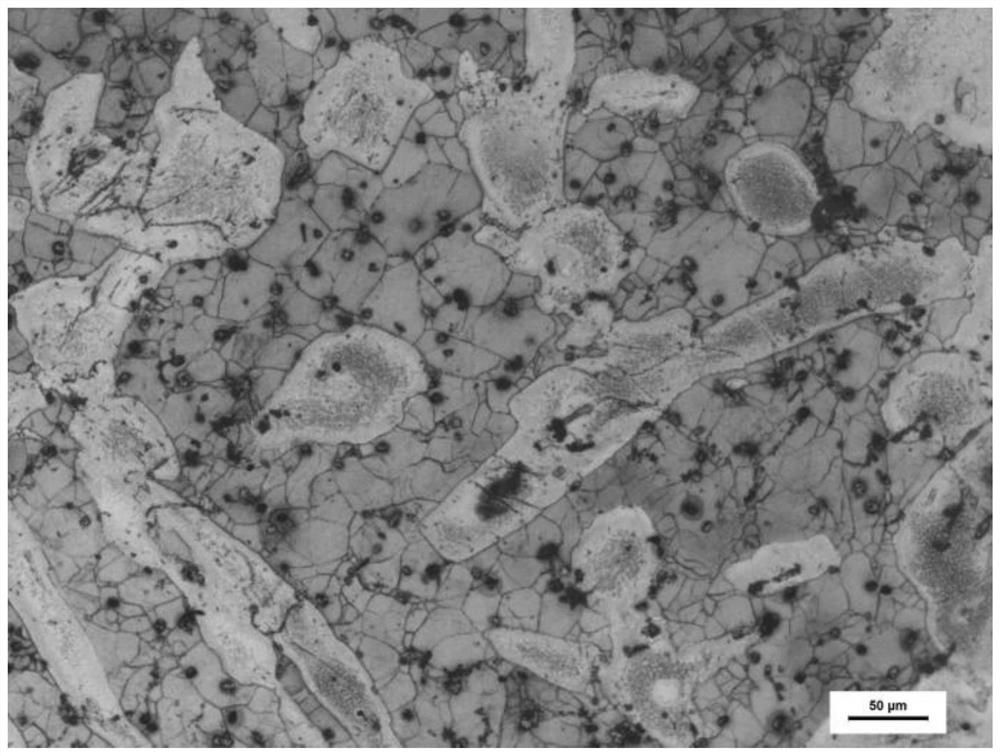

A technology of superplasticity and warm extrusion, applied in metal extrusion forming tools, metal extrusion, metal extrusion dies, etc., can solve problems such as poor high temperature resistance, uneven composition, easy corrosion, etc., to improve mechanical properties , Improvement of mechanical properties, effect of material grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment discloses a kind of preparation method of feed, comprises the following steps:

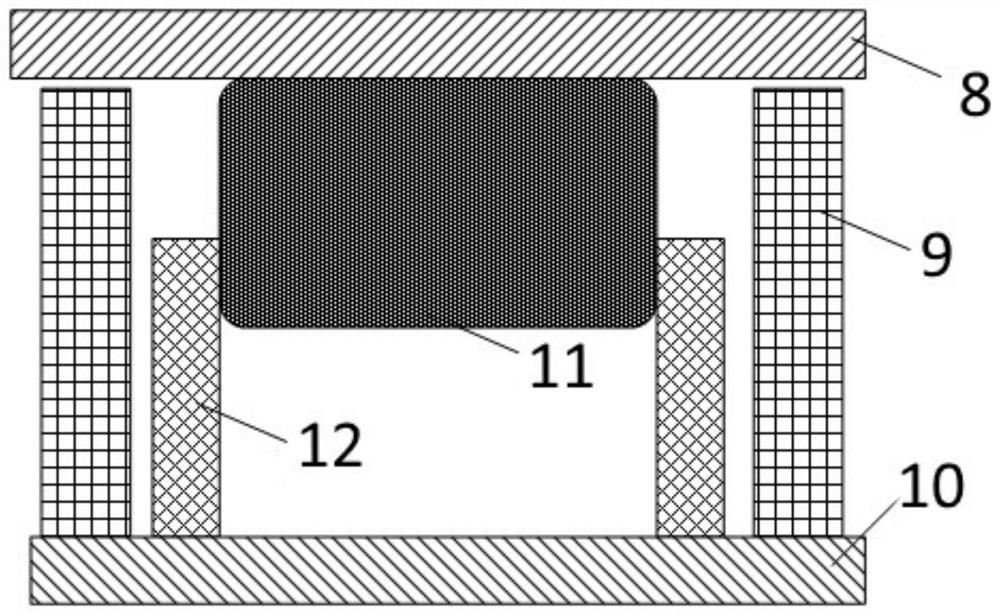

[0027] Step 1, carrying out numerical simulation on the forming member, and determining the form and process flow of the forming die 12;

[0028] In a further embodiment, a typical magnesium-lithium alloy cylindrical part main cabin body 1 with reinforcing ribs, the magnesium-lithium alloy blank is set as a plastic body in the ABAQUS software, the mold 12 is set as a rigid body, and the temperature of the mold 12 Set to 350°C. During the simulation process of positive and negative extrusion, the upper pressing head 6 is the active mold 12, which is responsible for applying pressure. Boundary conditions are applied so that the die remains stationary. The blank will flow along the gap between the lower die and the side wall to fill the die 12 along with the movement of the upper ram 6 to complete the forming of the lower cylinder. After completing the replacement of the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com