Preparation method of a three-dimensional aminated carbon nanotube array/stretchable textile fiber electrode material

A technology of three-dimensional aminated carbon and nanotube arrays, which is applied in the field of electrochemical materials, can solve the problems of constructing a blank of three-dimensional flexible conductive materials, and achieves the effects of good conductivity, improved lifting force, and increased adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

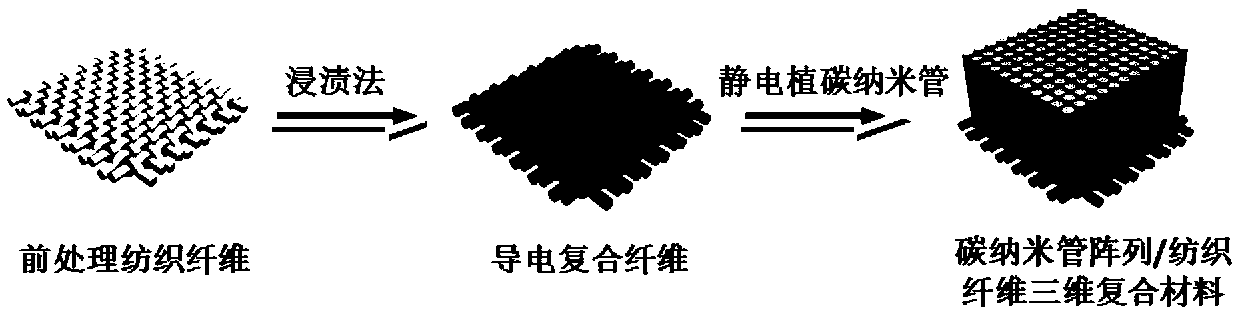

Method used

Image

Examples

Embodiment 1

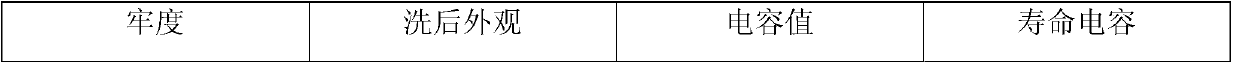

[0046] After the pretreatment, the high-content cationic modified polyester / spandex blended knitted jersey was immersed in the composite preparation solution containing sodium dodecylbenzenesulfonate (10g / L) and aminated carbon nanotubes (1.6g / L). Immersed at room temperature for 5 minutes, dried at 120°C, and repeated 5 times to obtain a conductive stretchable fiber substrate. Place the aminated carbon nanotubes in the electrodeposition treatment solution (mass fraction: potassium aluminum sulfate 6%, sodium silicate 3%, dispersant NNO 15%, penetrant JFC 4%), heat up to 60 ° C, bath ratio 50 : 1, the time is 60min, vacuum filtration and drying. The prepared conductive stretchable fiber substrate is evenly coated with graphene conductive adhesive, and the aminated carbon nanotubes that have been electro-treated are electrostatically implanted on the surface of the substrate on one side, the voltage is 50KV, and the distance between the plates is 120mm. for 5s. After implanta...

Embodiment 2

[0050] After the pretreatment, the high-content cationic modified polyester / spandex blended knitted jersey was immersed in the composite preparation solution containing sodium dodecylbenzenesulfonate (15g / L) and aminated carbon nanotubes (1.6g / L). Immersed at room temperature for 5 minutes, dried at 120°C, and repeated 5 times to obtain a conductive stretchable fiber substrate. Place the aminated carbon nanotubes in the electrodeposition treatment solution (mass fraction: potassium aluminum sulfate 8%, sodium silicate 4%, dispersant NNO 20%, penetrant JFC 4%), heat up to 60 ° C, bath ratio 50 : 1, the time is 60min, vacuum filtration and drying. The prepared conductive stretchable fiber substrate is uniformly coated with graphene conductive glue, and the aminated carbon nanotubes that have been electro-treated are implanted on the surface of the substrate electrostatically on one side, the voltage is 50KV, and the distance between the plates is 140mm. for 5s. After implantat...

Embodiment 3

[0054] After the pretreatment, the high-content cationic modified polyester / spandex blended knitted jersey was immersed in the composite preparation solution containing sodium dodecylbenzenesulfonate (15g / L) and aminated carbon nanotubes (1.6g / L). Immersed at room temperature for 5 minutes, dried at 120°C, and repeated 8 times to obtain a conductive stretchable fiber substrate. Place the aminated carbon nanotubes in the electrodeposition treatment solution (mass fraction: aluminum potassium sulfate 8%, sodium silicate 5%, dispersant NNO 15%, penetrant JFC 6%), heat up to 60 ° C, bath ratio 50 : 1, the time is 60min, vacuum filtration and drying. The prepared conductive stretchable fiber substrate is evenly coated with graphene conductive adhesive, and the aminated carbon nanotubes that have been electro-treated are electrostatically implanted on the surface of the substrate on one side, the voltage is 50KV, and the distance between the plates is 120mm. for 5s. After implanta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com