High-strength single-phase (alpha phase) Mg-Li alloy material and preparation method thereof

A magnesium-lithium alloy, high-strength technology is applied in the field of high-strength single-phase magnesium-lithium alloy materials and their preparation, which can solve the problems of no longer significant improvement in alloy strength and decrease in plasticity, and achieves improved strength, improved application, and increased quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

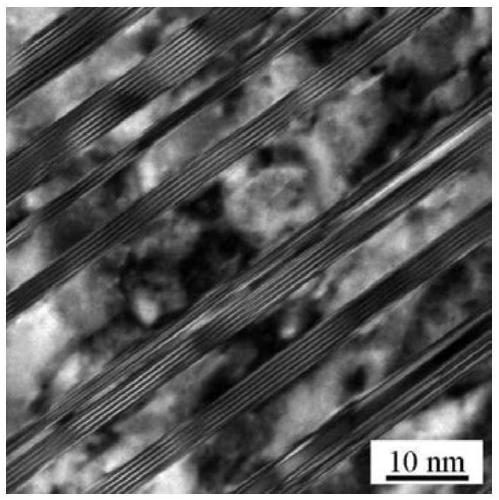

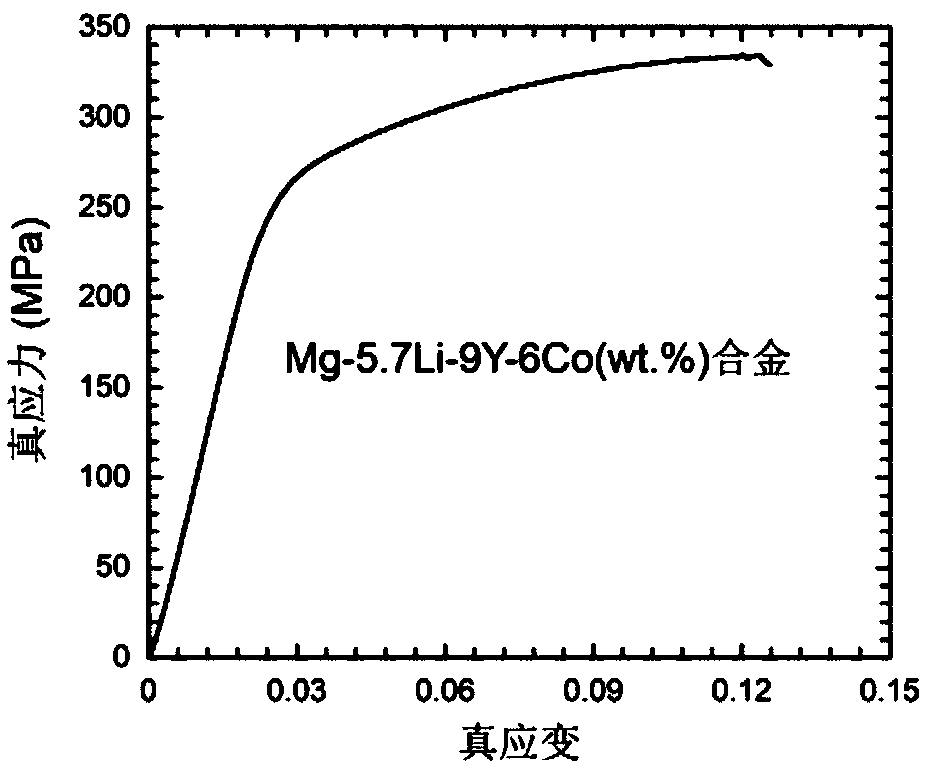

[0043] A high-strength single-phase (α-phase) magnesium-lithium alloy material, the magnesium-lithium alloy material contains the following components by weight: Li: 5.7wt%, Y: 9.0wt%, Co: 6.0wt%, the rest is Mg and not Avoided impurities, the content of unavoidable impurities is ≤0.03wt%.

[0044] A method for preparing a high-strength single-phase (α-phase) magnesium-lithium alloy material, comprising:

[0045] 1) vacuum smelting the preheated metal raw materials to obtain alloy liquid, the vacuum smelting adopts electromagnetic induction heating with a frequency of 0.065 MHz, and then casts it into a mold to cool to obtain cast magnesium-lithium alloy;

[0046] 2) Homogenizing the obtained cast magnesium-lithium alloy at a temperature of 240° C. for 9 hours;

[0047] 3) The homogenized magnesium-lithium alloy is subjected to low-temperature rolling, the rolling temperature of the first pass is 355°C, the roll speed is 11r / min, the reduction is 22.5%, and air-cooled after 1...

Embodiment 2

[0049] A high-strength single-phase (α-phase) magnesium-lithium alloy material, comprising the following components by weight percentage: Li: 2.6wt%; Tb: 7.5wt%; Co: 4.5wt%, the rest is Mg and unavoidable impurities, not The content of avoided impurities is ≤0.03wt.%.

[0050] A method for preparing a high-strength single-phase (α-phase) magnesium-lithium alloy material, comprising:

[0051] 1) vacuum smelting the preheated metal raw material to obtain alloy liquid, the vacuum smelting adopts electromagnetic induction heating with a frequency of 0.05MHz, and then casts it into a mold to cool to obtain cast magnesium-lithium alloy;

[0052] 2) Homogenizing the obtained cast magnesium-lithium alloy at a temperature of 220° C. for 8 hours;

[0053] 3) The homogenized magnesium-lithium alloy is subjected to low-temperature rolling, the rolling temperature of the first pass is 352°C, the roll speed is 10r / min, the reduction is 20%, and air cooling is carried out after 12 minutes o...

Embodiment 3

[0055] A high-strength single-phase (α-phase) magnesium-lithium alloy material, comprising the following components by weight: Li: 0.1wt%; Y: 6.0wt%; Co: 3.0wt%, and the rest are Mg and unavoidable impurities. The content of avoided impurities is ≤ 0.03 wt%.

[0056] A method for preparing a high-strength single-phase (α-phase) magnesium-lithium alloy material, comprising:

[0057] 1) vacuum smelting the preheated metal raw material to obtain alloy liquid, the vacuum smelting adopts electromagnetic induction heating with a frequency of 0.08MHz, and then casts it into a mold to cool to obtain cast magnesium-lithium alloy;

[0058] 2) homogenizing the obtained cast magnesium-lithium alloy at a temperature of 250° C. for 10 hours;

[0059] 3) The homogenized magnesium-lithium alloy is subjected to low-temperature rolling, the rolling temperature of the first pass is 358°C, the roll speed is 12r / min, the reduction is 25%, and air cooling is carried out after 14 minutes of heat pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com