Method for preparing copper/molybdenum composite board with molybdenum fibers by accumulative roll bonding

A composite board and fiber technology, which is applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of preparing molybdenum fiber copper/molybdenum composite boards without mentioning lamination, and achieves high yield and high production efficiency. Simple process and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of copper / molybdenum composite board with low molybdenum fiber density

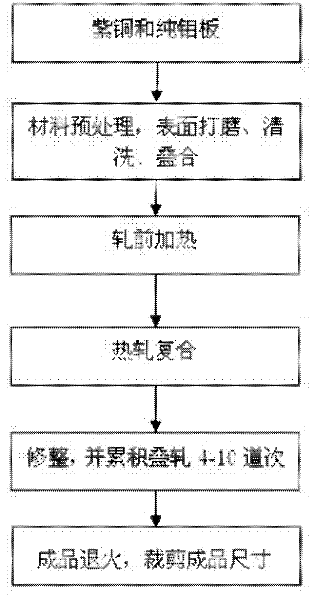

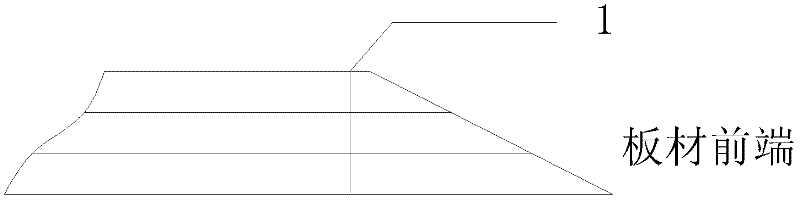

[0027] see figure 1 , the preparation of copper / molybdenum composite board with low molybdenum fiber density is implemented according to the following steps:

[0028] 1. Preparation of molybdenum plate and copper plate

[0029] Take industrial pure molybdenum blanks, roll them into 0.5mm-2.5mm molybdenum plates under the condition of 1000℃~1350℃, carry out heat treatment, and cool with the furnace;

[0030] Take the industrial pure copper plate, the thickness of the copper plate is: 2.0mm ~ 6.0mm, put it in the annealing furnace, anneal at 600 ℃ for 1 hour, and cool with the furnace;

[0031] Grind the surface of the above-mentioned molybdenum plate and copper plate with a water grinder to make the surface roughness Ra≤7~8μm; and clean the polished surface with acetone to remove oil stains, oxides and impurities on the surface of the molybdenum plate and copper plate, and u...

Embodiment 2

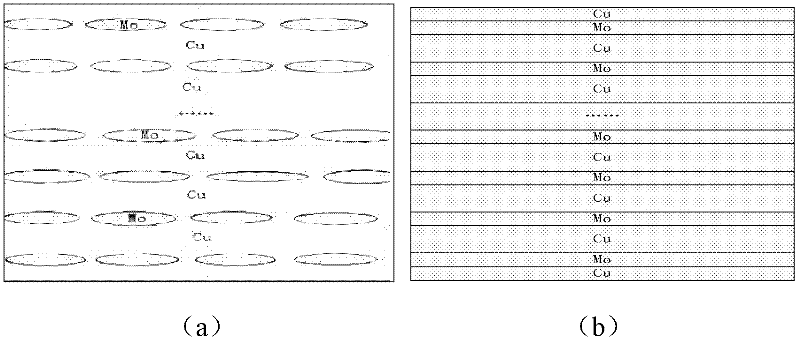

[0037] Example 2: Preparation of copper / molybdenum composite board with high molybdenum fiber density

[0038] This embodiment is prepared according to the process in Example 1, the difference is that in repeating the operation from step 1 to step 5, it is necessary to carry out 8 to 10 passes of cumulative rolling, and then perform the heat treatment of step 6, that is A copper / molybdenum composite board with a higher molybdenum fiber density is obtained.

[0039] After testing, the longitudinal tensile strength of the copper / molybdenum composite board prepared in the above embodiment is 180-360 MPa, the transverse tensile strength is 390-620 MPa, and the elongation is 25%-45%. Subsequent selective rolling or shearing can be done according to the required size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com