Ball milling-accumulative roll bonding method for circulating solidification of pure titanium machining chips

A chip and ball milling technology, applied in the field of metal material processing, can solve problems such as unsolved problems, grain coarsening, weakening of material strength, etc., to eliminate pore defects, inhibit grain coarsening, prevent continuous distribution and Aggregate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

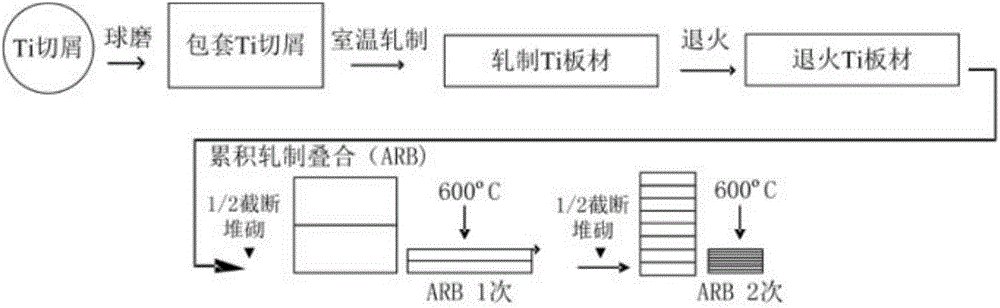

[0030] Such as figure 1 As shown, the ball milling-cumulative rolling lamination method of a kind of pure titanium chips cyclically solidified that the present invention proposes, comprises the following steps:

[0031] Step (1)-Ti chip recovery pretreatment: use the chips generated by end milling Ti 2 (ASTM Grade 2) as raw materials, collect the chips, and use Inductively coupled plasma atomic emission spectroscopy (ICP for short) -AES) to analyze its chemical composition (mass percentage, wt.%), and the analysis results are shown in Table 1. It can be seen from Table 1 that the chemical composition (oxygen content) of the milled grade 2 Ti chips meets the ASTM standard range. At the same time, 99.9% ethanol is used to clean ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com