Preparation method of ultrafine grain rare earth magnesium alloy

A technology of rare earth magnesium and ultra-fine crystals, applied in the field of alloys, can solve the problems of difficult control of magnesium alloy powder metallurgy process, unfavorable industrial production, high equipment cost, etc., and achieve the effect of improving dispersion strengthening effect, low equipment cost, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

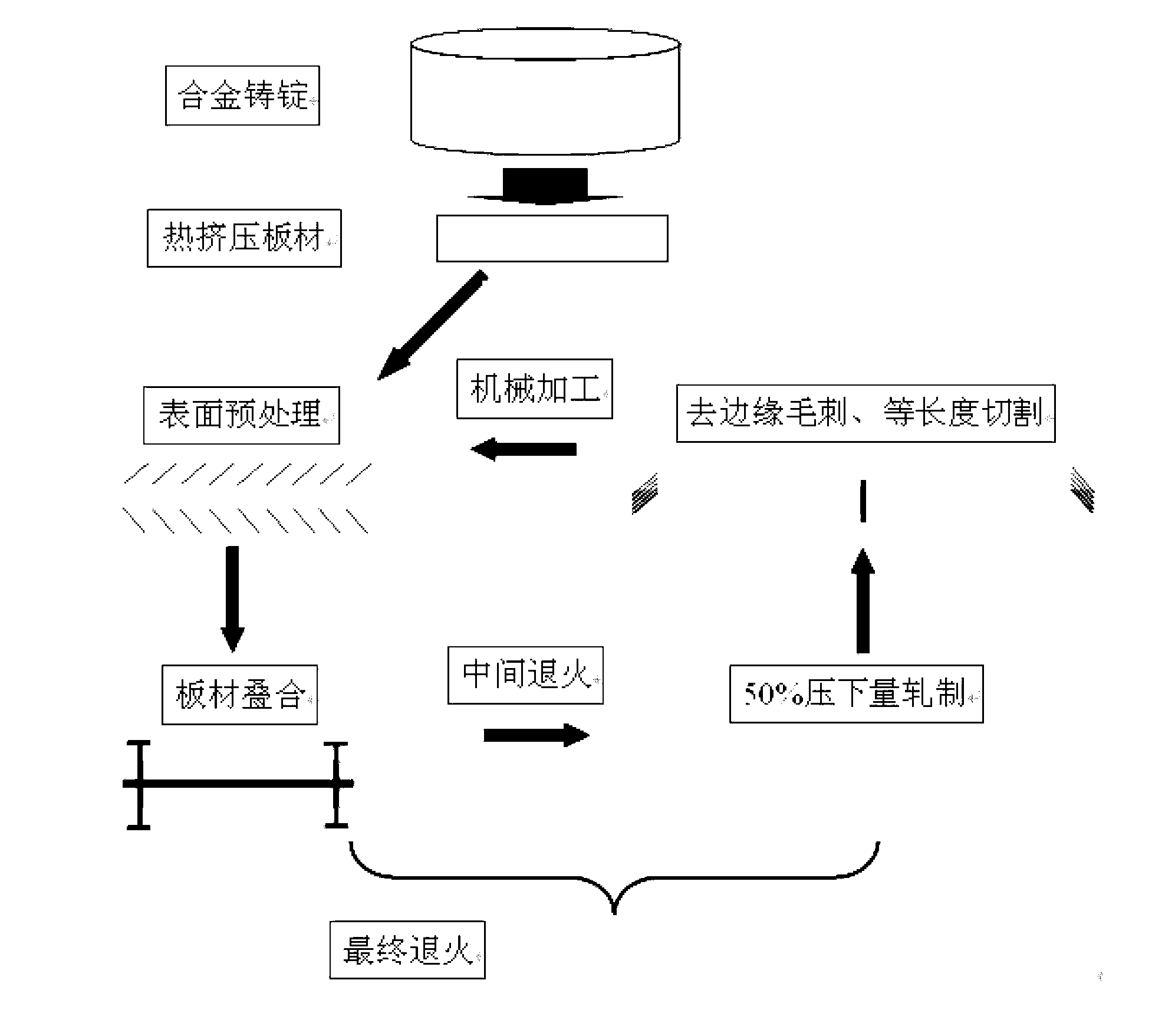

[0029] The invention discloses a method for preparing an ultrafine-grain rare earth magnesium alloy, which comprises the following steps:

[0030] a) performing solution treatment on the rare earth magnesium alloy ingot to obtain the solution treated rare earth magnesium alloy;

[0031] b) subjecting the solution-treated rare earth magnesium alloy obtained in step a) to thermal deformation processing to obtain a thermally deformed rare earth magnesium alloy plate, and the temperature of the thermal deformation processing is 350°C to 450°C;

[0032] c) Carrying out the hot-deformed rare earth magnesium alloy plate material obtained in the step b) through accumulative stack rolling with a rolling reduction of 50% in a single pass, and annealing to obtain an ultrafine-grained rare earth magnesium alloy.

[0033] The invention prepares high-performance ultra-fine-grained rare earth magnesium alloy plates through thermal deformation processing-cumulative stack rolling composite pro...

Embodiment 1

[0066] (1) Casting of Mg-Y-Zn alloy: first, clean the surface of pure magnesium ingot with alcohol, rinse with deionized water, dry it, put it into a well-type resistance melting furnace, and feed it with a volume ratio of 40:1. CO 2 and SF 6 Protective gas, heated to 750°C, after the pure magnesium ingot is melted, add pure zinc ingot and Mg-Y rare earth master alloy preheated at 300°C for 30 minutes, manually stir and let stand for 10 minutes, then cool to 720°C and pour 45 #Casting is carried out in a steel permanent cylindrical mold, the ingot diameter is 90mm, and the alloy composition is Mg-6.0wt%Y-2.0wt%Zn.

[0067] (2) Preparation of Mg-Y-Zn alloy sheet: heat the alloy ingot at 330°C for 4h, raise the temperature to 400°C for 8h, and perform water quenching at 70°C, then hot-extrude the alloy at 350°C ℃, the extrusion ratio is 20:1, and the extrusion rate is 2.0mms -1 .

[0068] (3) Surface pretreatment of the alloy plate: process the Mg-Y-Zn alloy plate prepared b...

Embodiment 2

[0075] (1) Casting of Mg-Y-Zn alloy: first, clean the surface of pure magnesium ingot with alcohol, rinse with deionized water, dry it, put it into a well-type resistance melting furnace, and feed it with a volume ratio of 40:1. CO 2 and SF 6 Protective gas, heated to 750°C, after the pure magnesium ingot is melted, add pure zinc ingot and Mg-Y rare earth master alloy preheated at 300°C for 30 minutes, manually stir and let stand for 10 minutes, then cool to 720°C and pour 45 #Casting is carried out in a steel permanent cylindrical mold, the ingot diameter is 90mm, and the alloy composition is Mg-10.0wt%Y-4.0wt%Zn.

[0076] (2) Preparation of Mg-Y-Zn alloy sheet: heat the alloy ingot at 330°C for 4h, heat it up to 500°C for 24h, and perform water quenching at 70°C, then hot-extrude the alloy at 450°C ℃, the extrusion ratio is 5:1, and the extrusion rate is 0.2mms -1 .

[0077] (3) Surface pretreatment of the alloy plate: process the Mg-Y-Zn alloy plate prepared by hot extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com