A kind of reinforced lightweight metal matrix composite material based on mn-cu alloy and its preparation method

A composite material and metal-based technology, applied in metal rolling and other directions, can solve the problems of poor bonding between the metal matrix and the particle interface, long material preparation period, uneven particle dispersion, etc. , Overcome the effect of complex equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

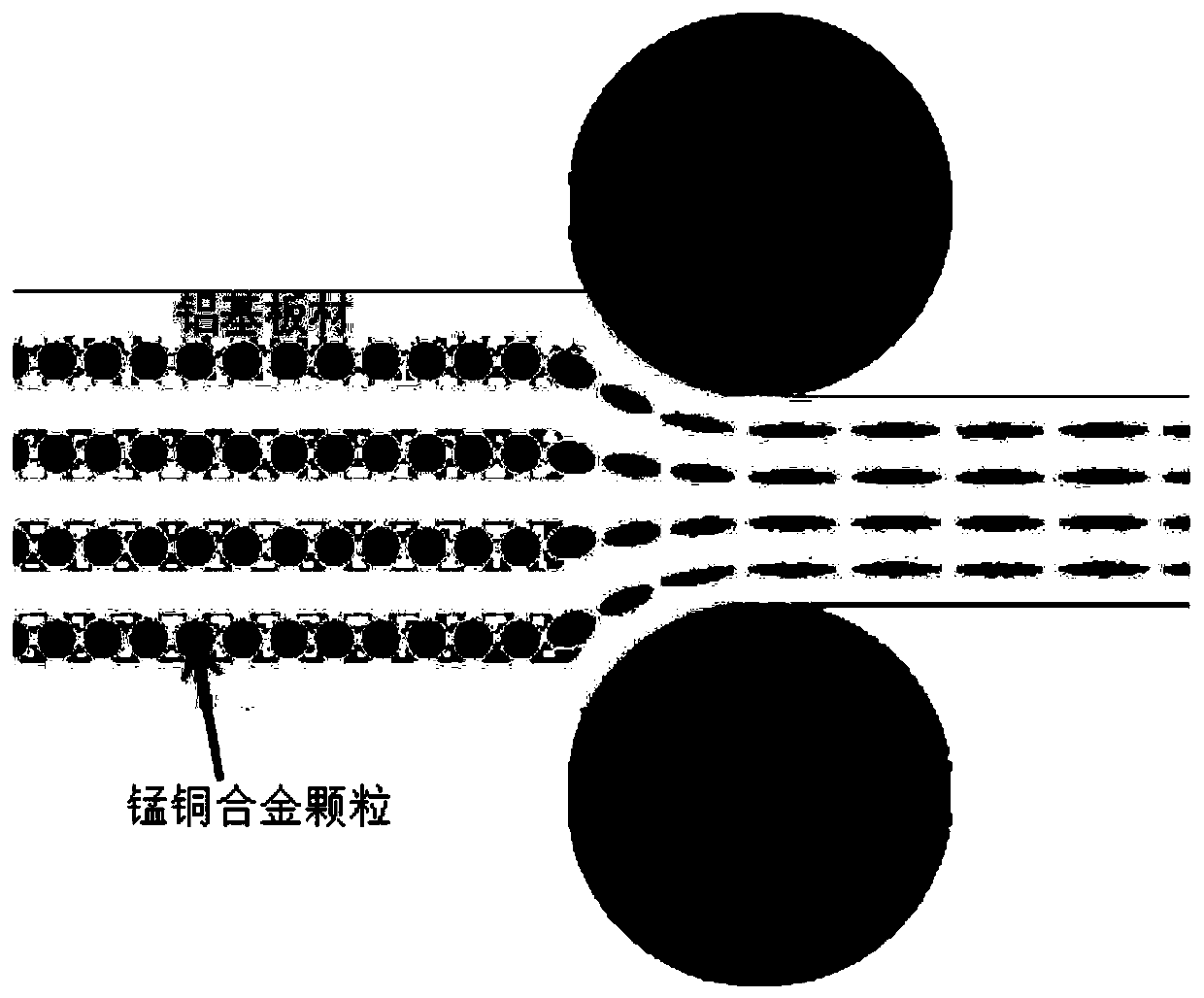

[0034] This embodiment provides a method for preparing a reinforced Al-based lightweight high-damping composite material based on Mn-Cu alloy, such as figure 1 shown, including the following steps:

[0035] Step 1: Surface treating the Al substrate to remove surface metal oxides to obtain a metal substrate to be processed;

[0036] Step 2: Disperse the Mn-Cu alloy particles in deionized water, and then uniformly precipitate on the surface of the metal substrate in step 1, and then cover the metal substrate in step 1 to obtain the alternate layered arrangement of Mn-Cu alloy and the metal substrate in step 1 Composite substrate; wherein, the size of the Mn-Cu alloy particles is 1um-1000um, the thickness of the single-layer metal substrate is 1um-10cm, and the total mass of the Mn-Cu alloy accounts for 50% of the total mass of the entire composite substrate;

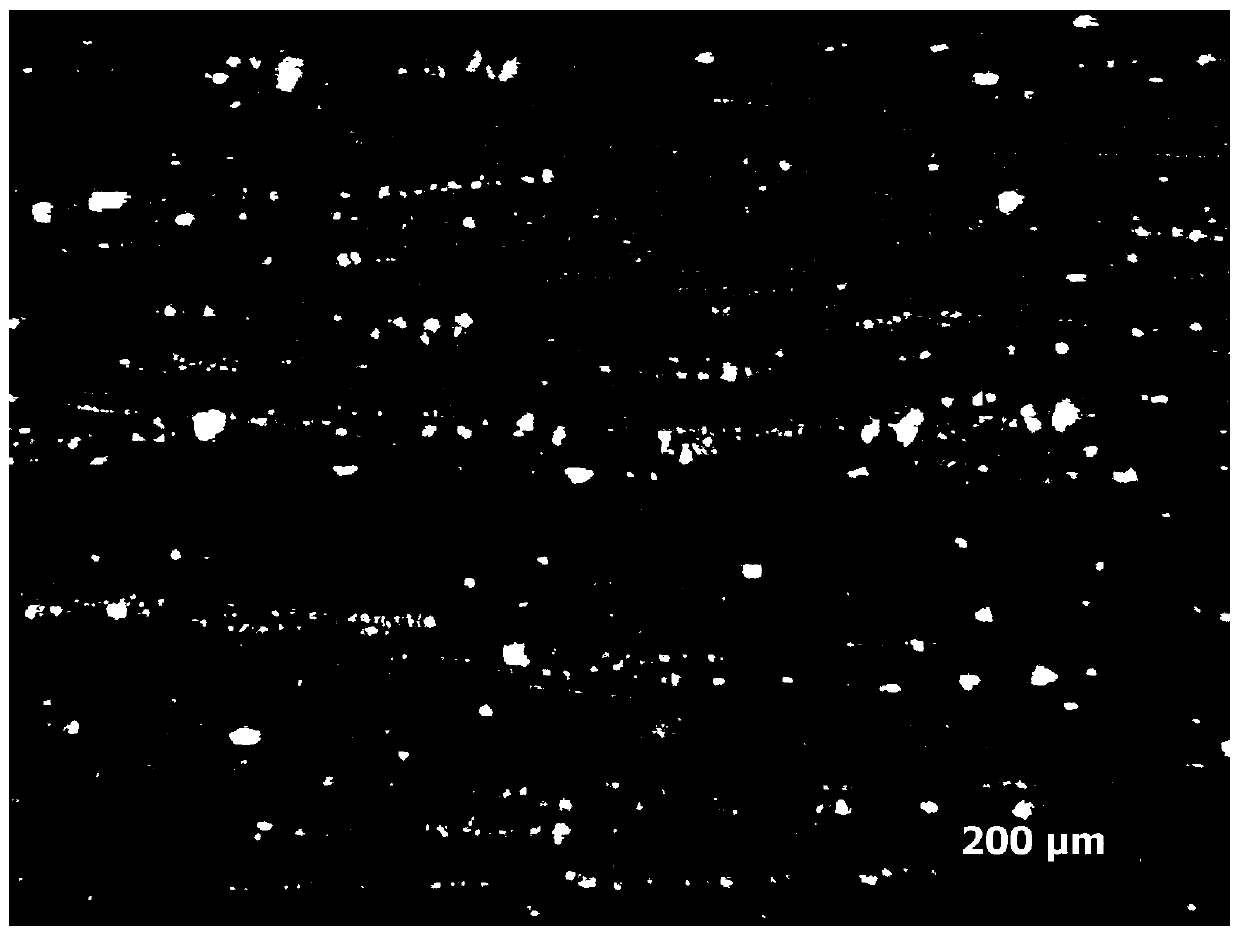

[0037] Step 3: The composite substrate in step 2 is cumulatively rolled and welded by hot rolling to obtain a particle-di...

Embodiment 2

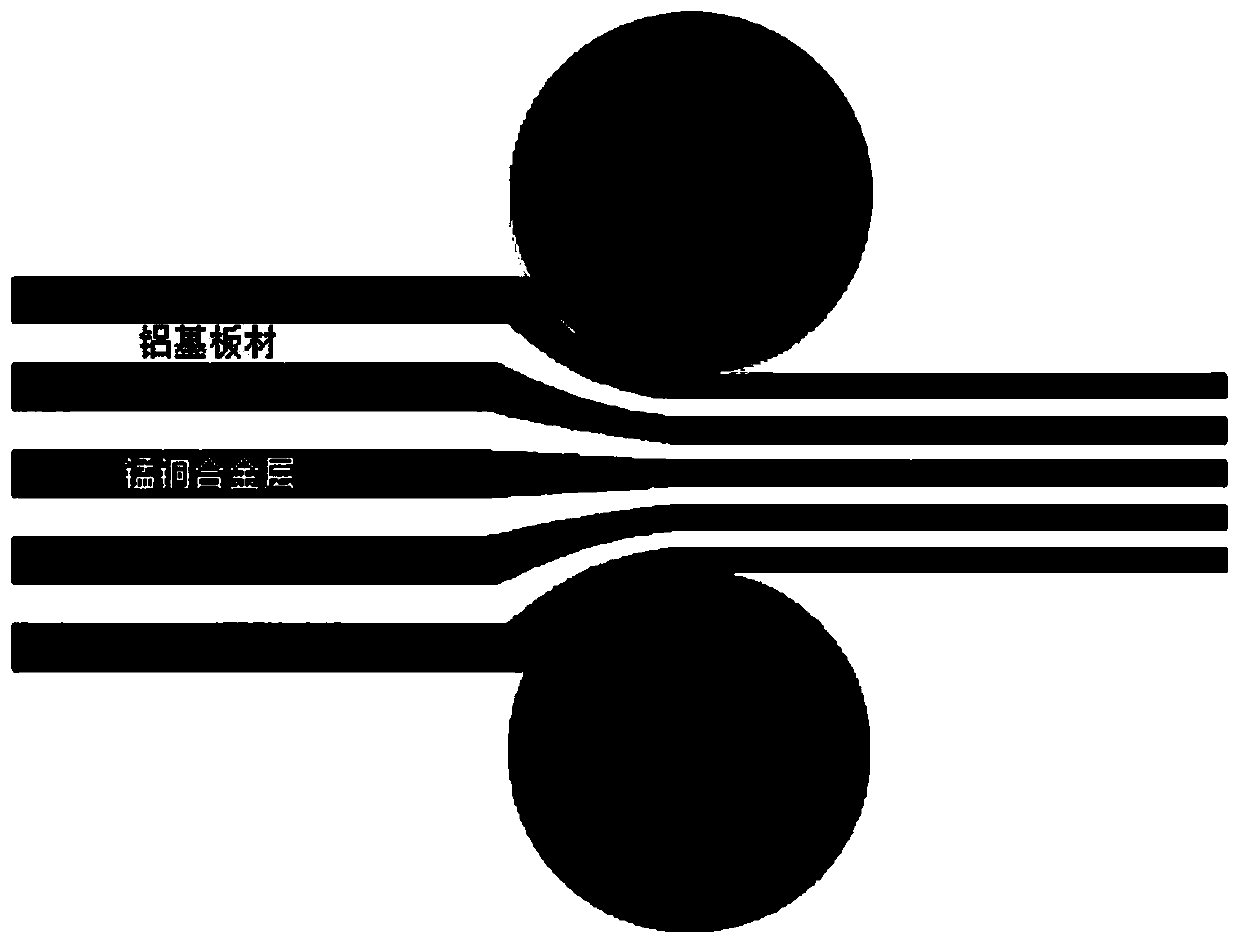

[0044] This embodiment provides a method for preparing a reinforced Al-based lightweight high-damping composite material based on Mn-Cu alloy, such as figure 2 shown, including the following steps:

[0045] Step 1: Surface treating the Al substrate to remove surface metal oxides to obtain a metal substrate to be processed;

[0046] Step 2: surface-treat the Mn-Cu alloy sheet to remove the surface metal oxide, and then alternately stack it with the metal sheet of step 1, stacking 20 layers in total to obtain a composite substrate; wherein, the single-layer Mn-Cu alloy The thickness of the plate is 10nm-100um, the thickness of the single-layer metal substrate is 1um-10cm, and the total mass of the Mn-Cu alloy accounts for 30% of the total mass of the entire composite substrate;

[0047] Step 3: The composite substrate in step 2 is rolled and welded by hot rolling to obtain a particle-dispersed composite sheet or a composite sheet with a layered structure, wherein the hot rolli...

Embodiment 3

[0051] This embodiment provides a method for preparing a reinforced Mg-based lightweight high-damping composite material based on Mn-Cu alloy, wherein the lightweight substrate is a magnesium alloy foam substrate, and the number of stacked layers is 2 layers. Rolling method is carried out by rolling welding, the hot rolling temperature is 600°C, the cumulative number of rolling welding is 20 times, and intermittent annealing treatment at 200°C is carried out between each double rolling, and other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com