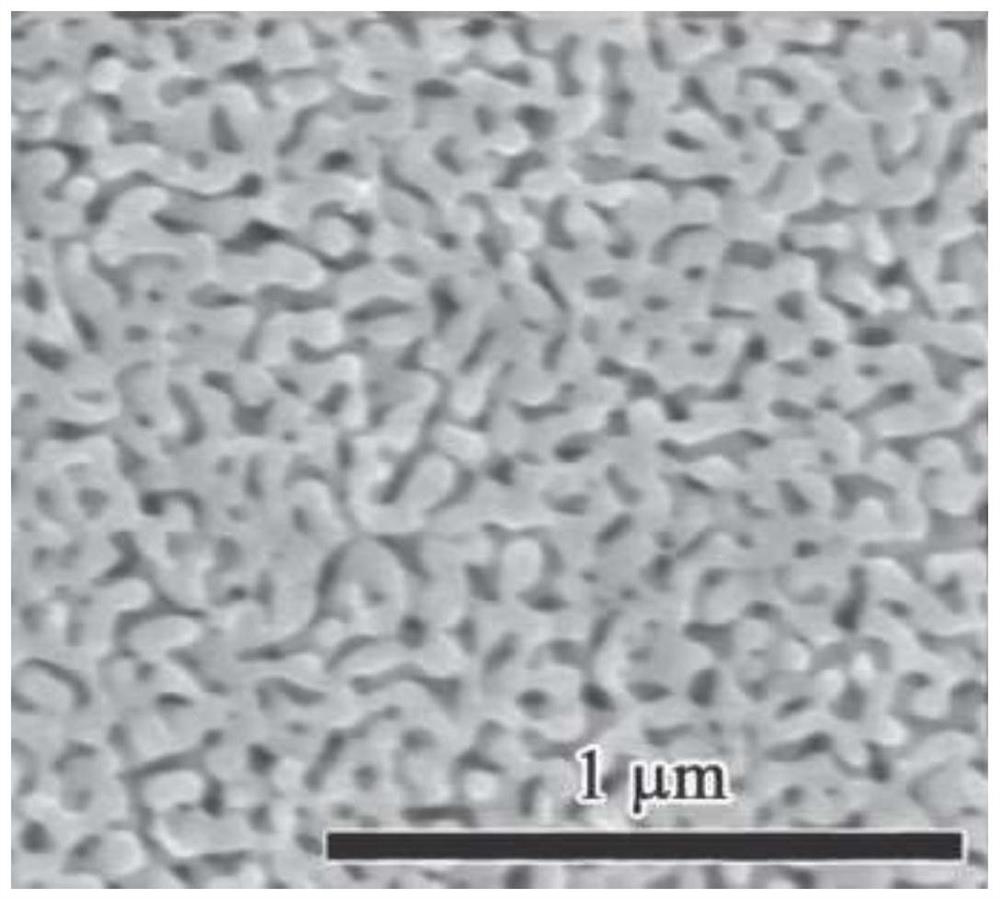

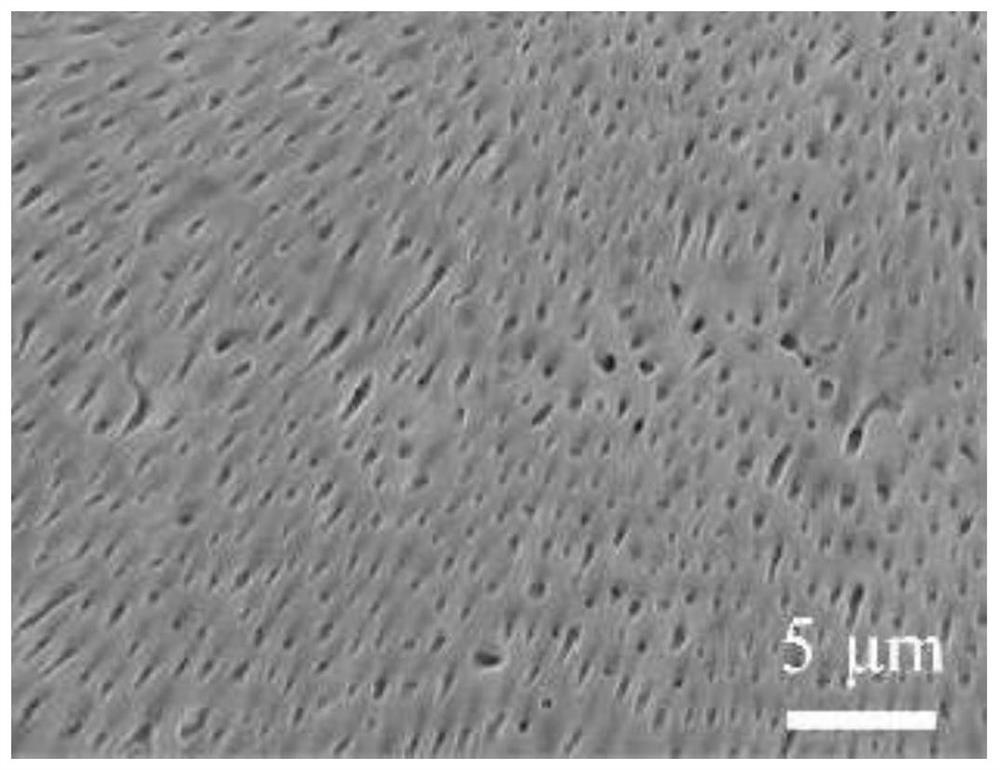

A kind of Mn-cu based submicro/nano porous high damping alloy and its preparation method

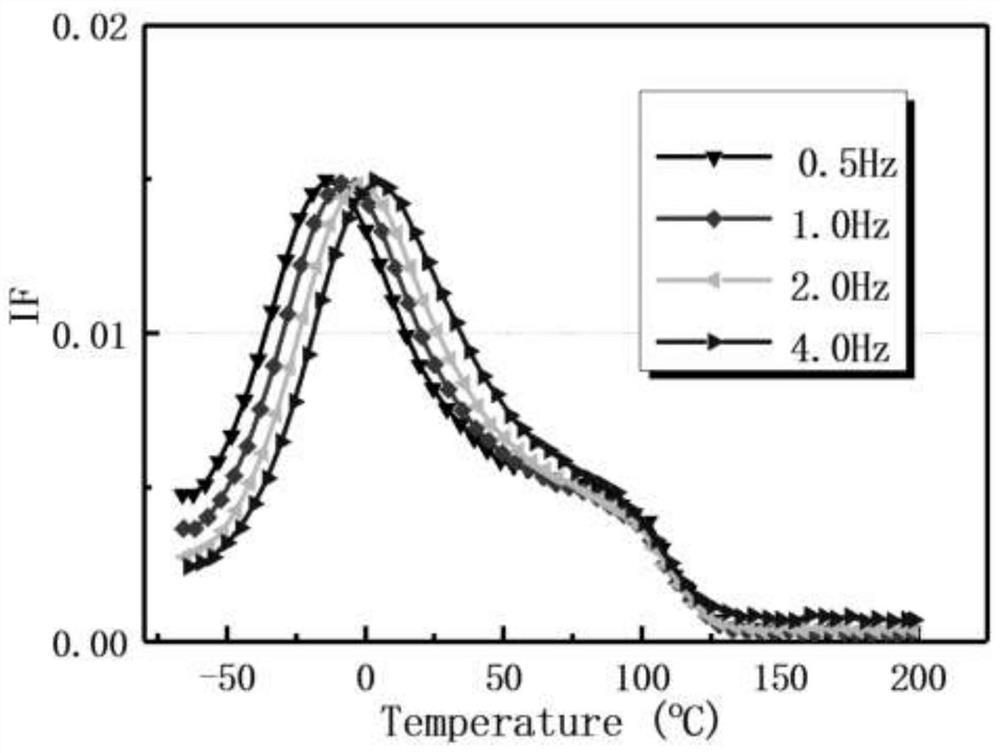

A high-damping alloy and nano-porous technology, applied in the field of Mn-Cu-based alloys, can solve problems such as uneven distribution, difficult process operation, and high foaming temperature, and achieve simple and easy-to-operate preparation process and excellent shock and noise reduction effects , Improving the effect of damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of Mn-Cu based micro-nano porous high damping alloy, its preparation method comprises:

[0029] (1) Put pure metal Mn and Cu as raw materials in an intermediate frequency vacuum induction furnace, evacuate to below 10Pa, continue to pump after power transmission and preheating, so that the vacuum degree is always kept below 10Pa; Fill the room with argon gas to make the pressure reach 0.005MPa, and at the same time, use 300kW power to melt the metal material quickly. After melting, let it stand for 15 minutes with 80kW power to complete refining; then let it stand for 20 minutes with 60kW power; The temperature of the melt is raised until the conjunctiva ruptures, and then pouring is started, and the pouring time is controlled within 5 minutes to obtain an alloy ingot, that is, a Mn-Cu-based alloy with an alloy composition of 70wt% Mn and 30wt% Cu;

[0030] (2) Place the Mn-Cu-based alloy obtained in step (1) in a vacuum heat treatment furnace, pass through argon...

Embodiment 2

[0036] A kind of Mn-Cu based micro-nano porous high damping alloy, its preparation method comprises:

[0037] (1) Put pure metal Mn and Cu as raw materials in an intermediate frequency vacuum induction furnace, evacuate to below 10Pa, continue to pump after power transmission and preheating, so that the vacuum degree is always kept below 10Pa; The room is filled with argon to make the pressure reach 0.001MPa, and at the same time, the metal raw material is melted rapidly with a power of 260kW. After melting, the power of 100kW is left to stand for 10 minutes to complete the refining; the power of the power is increased to 240kW, and pure metal Fe, Al is used as an alloy material, smelted for 8 minutes, and then left to stand for 15 minutes with a power supply of 80kW; after that, the temperature of the melt is raised until the conjunctiva ruptures, and then pouring is started, and the pouring time is controlled within 7 minutes to obtain an alloy ingot, that is, the alloy compo...

Embodiment 3

[0042] A kind of Mn-Cu based micro-nano porous high damping alloy, its preparation method comprises:

[0043] (1) Put pure metal Mn and Cu as raw materials in an intermediate frequency vacuum induction furnace, evacuate to below 10Pa, continue to pump after power transmission and preheating, so that the vacuum degree is always kept below 10Pa; The room is filled with argon to make the pressure reach 0.002MPa, and at the same time, the metal raw material is melted rapidly with a power of 280kW. After melting, the power of 90kW is left to stand for 10 minutes to complete the refining; the power of the power is increased to 200kW, and pure metal Ni is added as For alloy materials, smelt for 10 minutes, and then stand still for 20 minutes with a power supply of 60kW; then raise the temperature of the melt until the conjunctiva ruptures, and then start pouring, and the pouring time is controlled within 6 minutes to obtain an alloy ingot, that is, the alloy composition is 80wt% Mn ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com