Preparation method of high-porosity Mn-Cu-based high-damping alloy with adjustable pore diameter and pore size

A high damping alloy, high porosity technology, used in metal processing equipment, transportation and packaging, etc., can solve the problems of different pore sizes, uneven distribution, low porosity, etc., and is suitable for large-scale industrial production, The preparation process is simple and easy to operate, and the effect of no mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

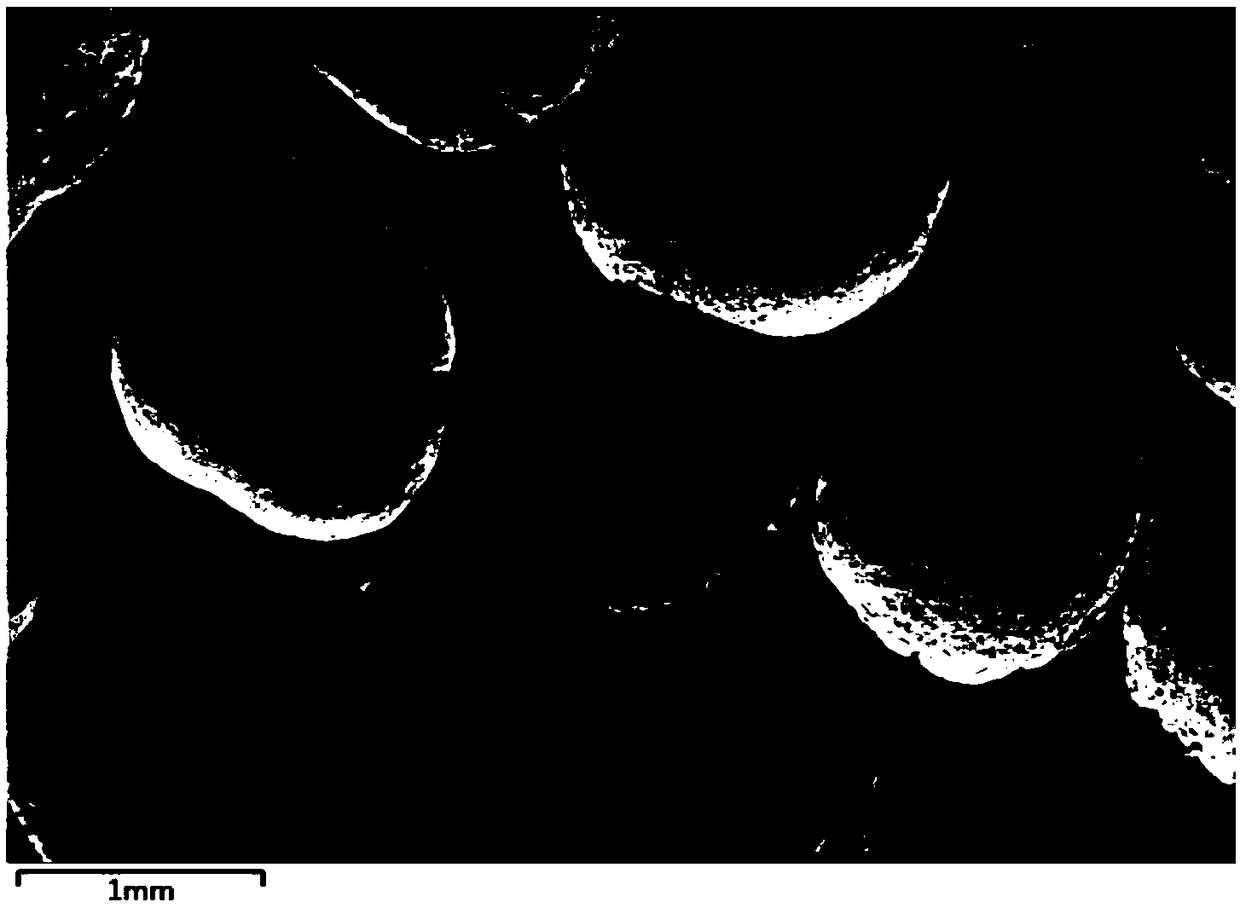

[0031] Example 1: Preparation of Mn-Cu binary alloy material with high porosity

[0032] Powder metallurgy method based on urea particles occupying position to make holes, the specific steps are

[0033] Step 1: Mix the Mn-Cu alloy particles with the urea particles in a mass ratio of 1:5, where the particle size of the Mn-Cu alloy particles is 500μm, the particle size of the urea particles is 100nm, and the shape is a sphere in a rotating body. Molecular solvent to avoid separation of the two phases, the polymer solvent is ethanol, and the addition amount is 3% of the total mass after mixing the Mn-Cu alloy particles and the urea particles, and the mixture is uniformly mixed to form a mixed powder.

[0034] Step 2: Place the above-mentioned mixed powder in a mold, cold-press forming, and the cold-pressing pressure of the cold-press forming is 250MPa to form an embryo;

[0035] Step 3: Soak the embryo body in water to dissolve the urea particles, the soaking time is 18h, and then put t...

Embodiment 2

[0037] Example 2: Preparation of high-porosity Mn-Cu-Fe ternary alloy material

[0038] Powder metallurgy method based on urea particles occupying position to make holes, the specific steps are

[0039] Step 1: Mix the Mn-Cu-Fe alloy particles and the urea particles in a mass ratio of 1:5, where the particle size of the Mn-Cu-Fe alloy particles is 500μm, the particle size of the urea particles is 200nm, and the shape is a cube. Molecular solvent to avoid the separation of the two phases, the polymer solvent is ethylene glycol, and the addition amount is 2% of the total mass after mixing the Mn-Cu-Fe alloy particles and the urea particles, and the mixture is uniformly mixed to form a mixed powder.

[0040] Step 2: Place the above-mentioned mixed powder in a mold, and cold-press the molding, the cold-pressing pressure of the cold-press molding is 300MPa to form an embryo;

[0041] Step 3: Soak the embryo body in water to dissolve the urea particles. The soaking time is 20h, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com