Method for manufacturing Mg-Li/Al material by means of accumulative roll-bonding

A technology of cumulative stacking and sheet rolling, applied in metal rolling, profile control, temperature control, etc., can solve the problem of not being able to improve corrosion resistance at the same time, and achieve the effect of high strength, good corrosion resistance, and improved alloy strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

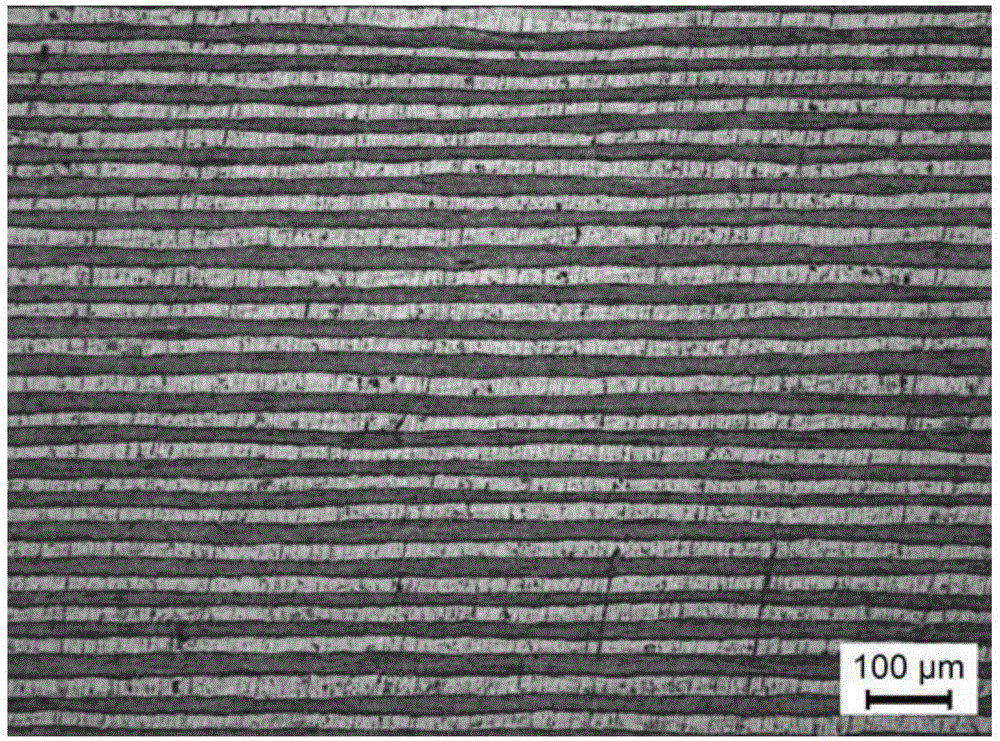

[0024] The chemical composition (mass percentage) of the magnesium-lithium alloy is: Li: 8.3%, Al: 3.2%, Zn: 1.3%, the balance is Mg, and the aluminum is 1070 pure aluminum.

[0025] Cumulative rolling of magnesium-lithium alloy sheets and aluminum sheets:

[0026] a) Cut the magnesium-lithium alloy plate and the aluminum plate to be accumulated and rolled into two pieces of equal size,

[0027] b) Clean and polish the surface of the plate.

[0028] c) Superimpose the treated magnesium-lithium alloy plate on the aluminum plate and punch holes in the four corners and fix them with rivets.

[0029] d) Carry out the first accumulative stack rolling on the fixed plate, the rolling reduction rate is 50%, the rolling temperature is 400°C, and the holding time before rolling is 15min.

[0030] d) Carry out the 2nd to 6th cumulative stack rolling with the same method, and the rolling parameters remain unchanged.

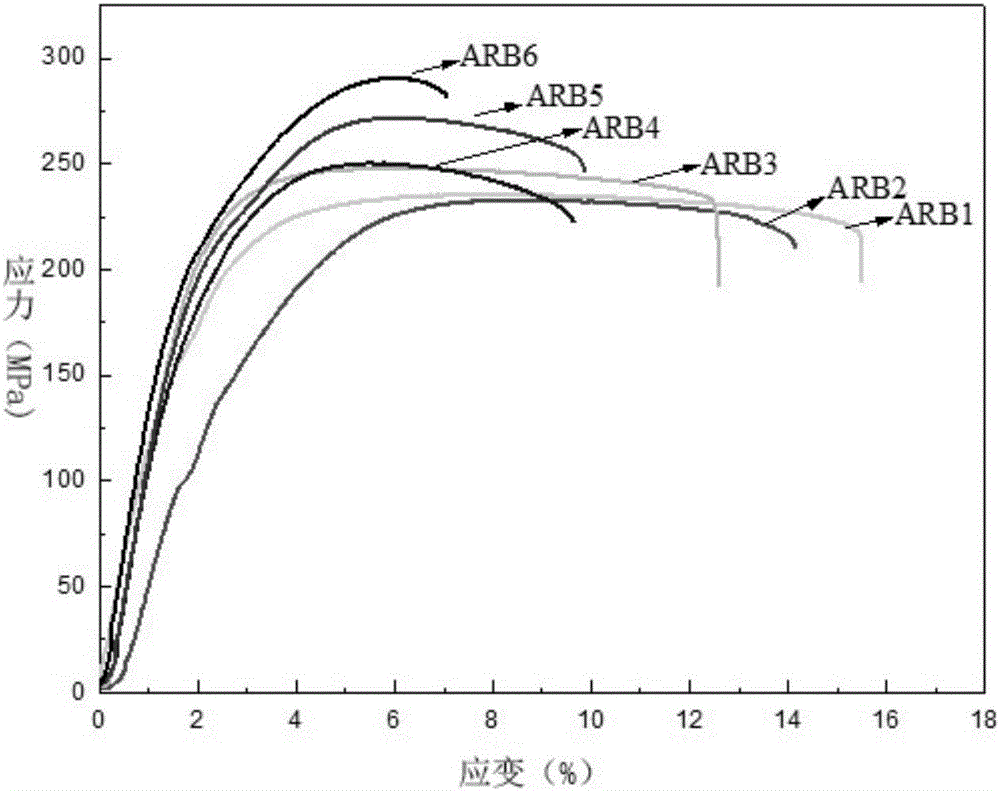

[0031] A Mg-Li / Al layered composite plate with both high strength an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com