Method for preparing alkene alloy by accumulative roll bonding technology and alkene alloy

A technology of cumulative stacking and olefinic alloying, applied in the direction of metal rolling, etc., can solve the problems of not being recognized by the industrial field, the adsorption of gas on the powder surface cannot be completely eliminated, and the industrial large parts cannot be prepared.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

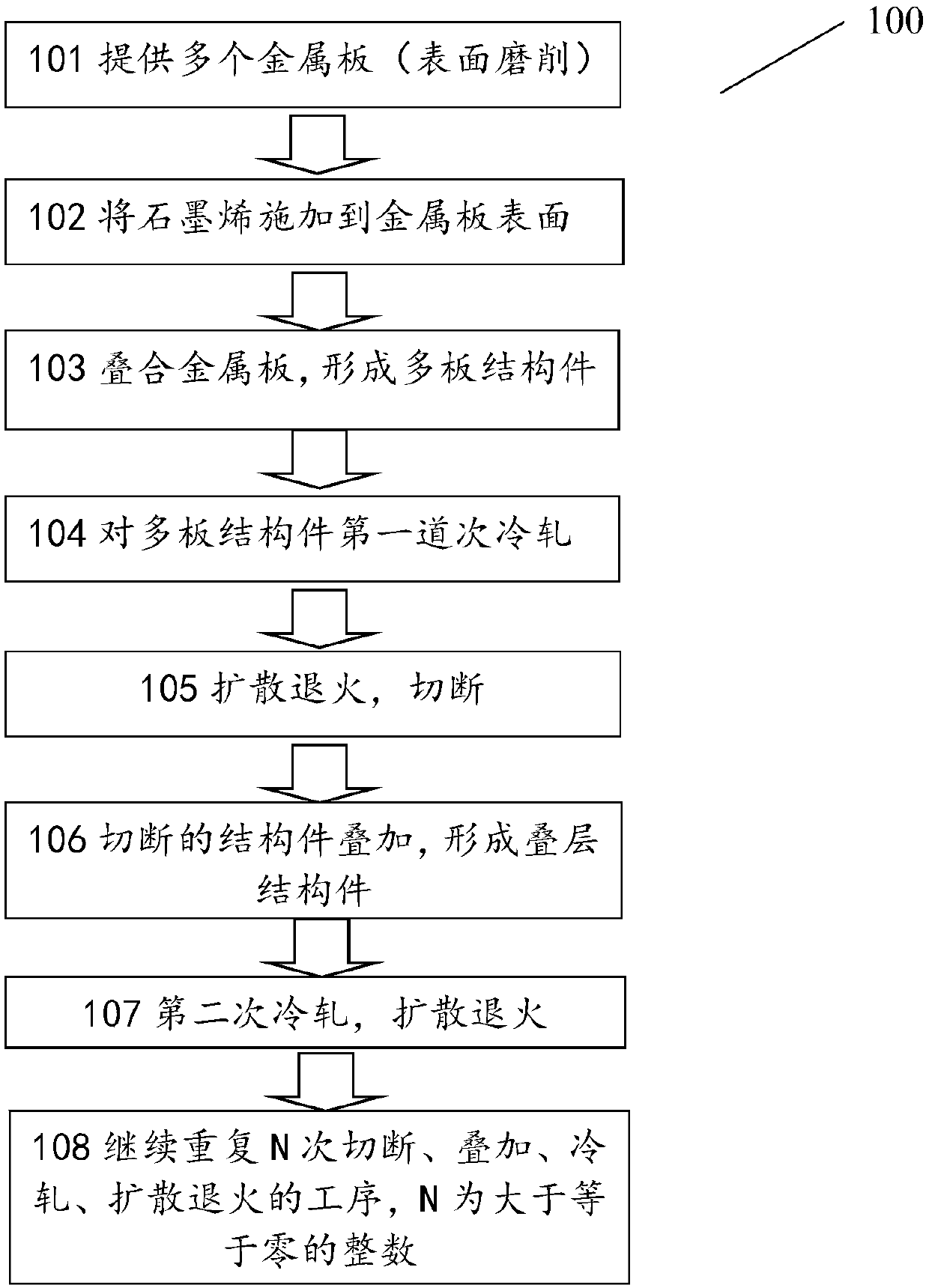

[0063] According to the first embodiment of the present invention, there is provided a method 100 for preparing an alkene alloy by a cumulative stack rolling process. Such as figure 1 As shown, the method 100 for preparing an alkene alloy by the cumulative stack rolling process of the first embodiment of the present invention includes:

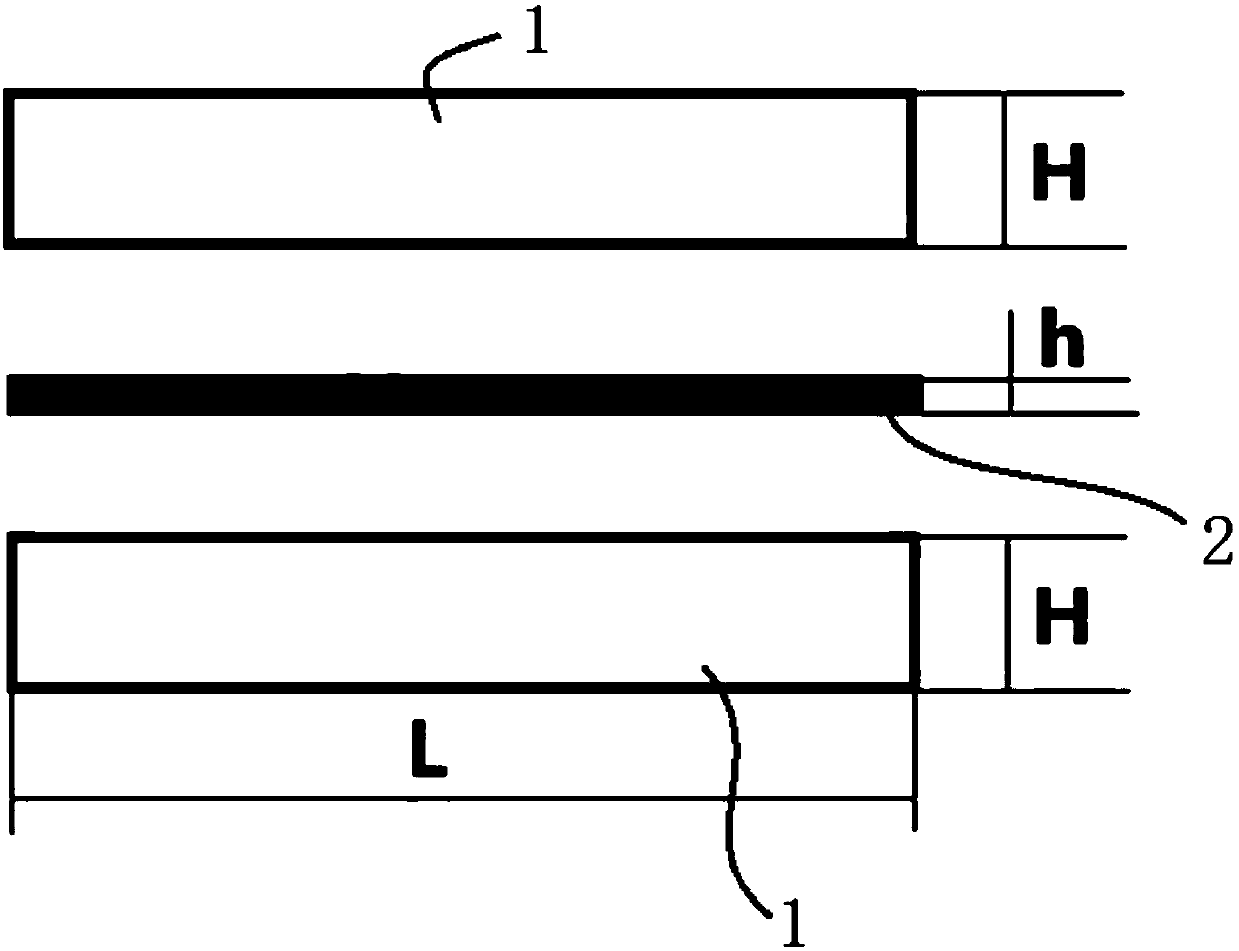

[0064] 101, providing multiple metal plates;

[0065] 102, graphene is applied to the metal plate surface;

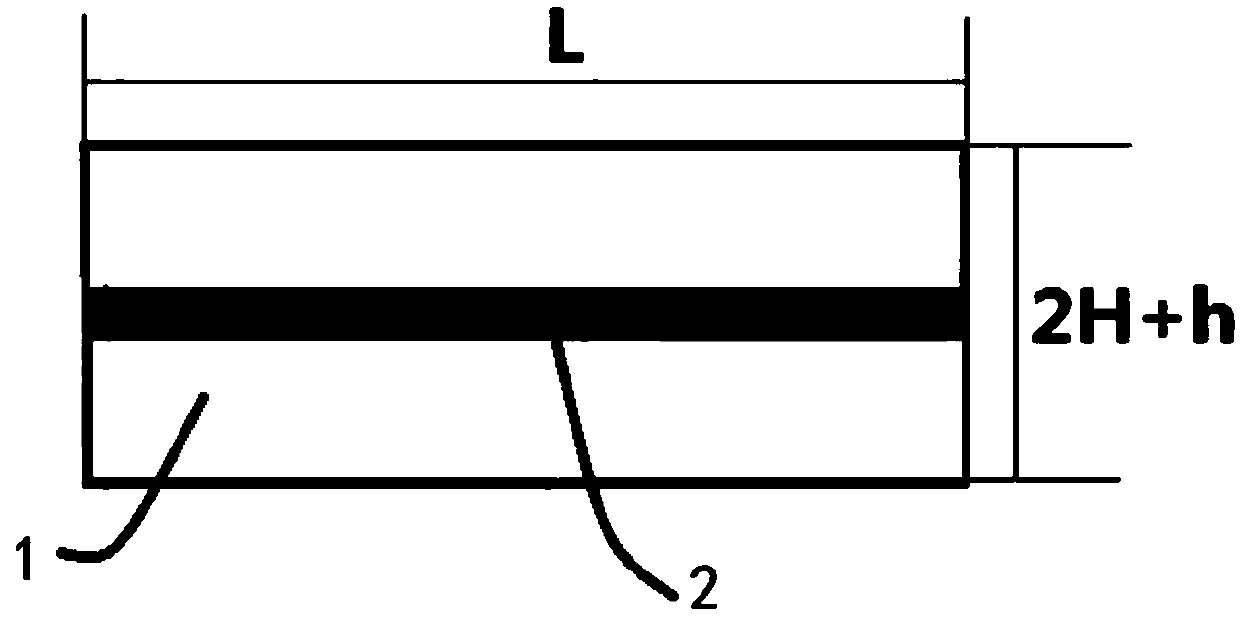

[0066] 103, stacking metal plates to form a multi-plate structure;

[0067] 104. Applying a first pass of cold rolling to the multi-plate structural member;

[0068] 105. Diffusion annealing and cutting off the structural member after the first pass of cold rolling;

[0069] 106, the cut structural parts are superimposed to form a laminated structural part;

[0070] 107, performing a second pass of cold rolling and diffusion annealing on the laminated structural member; and

[0071] 108. Continue repeating the steps of cutting, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com