Method for preparing alumina particle reinforced aluminum matrix composite

A technology of alumina particles and reinforced aluminum base, which is used in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of complex process, difficult large-scale industrial production, and high equipment requirements, and achieves simple equipment structure and easy industrialization. , the effect of a large size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

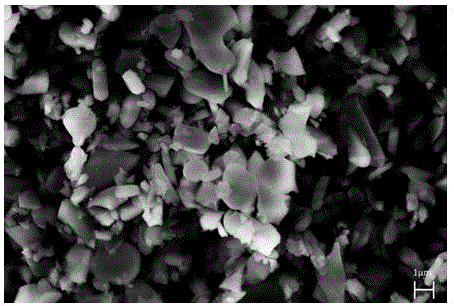

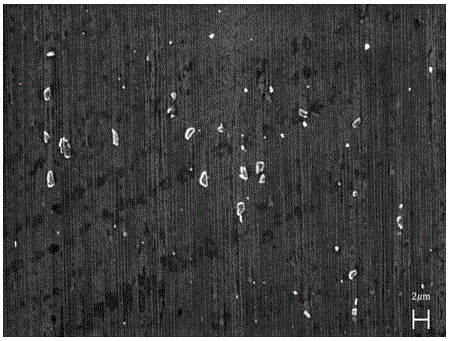

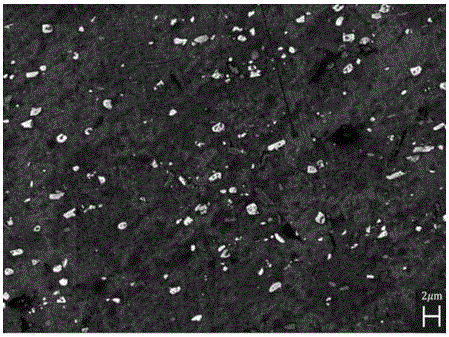

[0028] Example 1: Take alumina particles as reinforcement and 1060 pure aluminum sheet as matrix. In this embodiment, the aluminum content of the pure aluminum plate is 99.99%, and the size is: 100×20×0.25mm; the size of the alumina particles is 471nm. Adopt industrial rolling mill, rolling speed is 187mm / min.

[0029] First, cut out a pure aluminum sheet with a size of 100×20×0.25mm, and polish and clean the sample.

[0030] According to the volume of the pure aluminum sheet used, after calculation, different volume fractions of alumina particles are added to an appropriate amount of alcohol, and an ultrasonic cleaner is used to uniformly mix the alumina particles in the alcohol to form a suspension of alumina particles. Pour the suspension of alumina particles evenly onto the surface of the desired pure aluminum plate. After superimposing the pure aluminum sheet samples covered with alumina particles and fixing them with glue, use a half-folded stainless steel plate to cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com