Preparing method of Ti2AlC particle reinforced copper base composite

A copper-based composite material and particle reinforcement technology, which is applied in the field of composite material preparation, can solve the problems affecting the reinforcement effect of AlC particles, affecting the electrical and mechanical properties of composite materials, etc., to improve hardness and strength, easy preparation method, and improve dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of Ti 2 The preparation method of AlC particle reinforced copper-based composite material, comprises the steps:

[0024] Step 1: Put Ti 2 AlC particles are put into the mixed solution of alcohol and acetone, and dispersed at high speed to make dispersed Ti 2 AlC particle suspension;

[0025] Step 2: Perform surface treatment on the fully annealed oxygen-free pure copper plate to remove surface oil and oxide film;

[0026] Step 3: Distributed Ti 2 The AlC particle suspension is evenly sprayed on the surface of the treated pure copper plate, and then a layer of pure copper plate is laminated on the surface. After fastening, rolling, and cutting in half, repeat the above process, and continue to spray Ti 2 AlC particles, Ti as sprayed 2 The volume fraction of AlC is 2 to 4% of the pure copper plate, and the plate is obtained by cumulative rolling of multiple passes;

[0027] Step 4: Do not add Ti 2 AlC particles, the plate obtained in step 3 continues to be a...

Embodiment 1

[0037] In this embodiment, 2vol% Ti is added 2 Preparation of Ti by Cumulative Rolling of AlC Particles 2 AlC particle reinforced copper matrix composite material is taken as an example, the size of oxygen-free pure copper plate is 200mm×25mm×1mm, Ti 2 The size of AlC particles is 100-200nm. The Ti 2 The preparation method of AlC particle reinforced copper matrix composite material is:

[0038] Step 1: Add 0.45g of Ti 2 Put the AlC particles into the mixed solution of 200ml alcohol and acetone and disperse at high speed for 30min to make Ti 2 AlC particle suspension;

[0039] Step 2: Perform surface treatment on the fully annealed oxygen-free pure copper plate to remove surface oil and oxide film;

[0040] Step 3: Put half of the dispersed Ti 2 The AlC particle suspension is evenly sprayed on the surface of the copper plate, and then the two copper plates are superimposed, fastened, rolled, cut in half, repeat the above process, and add Ti 2 AlC particles, carry out 2 ...

Embodiment 2

[0044] In this embodiment, 2vol% Ti is added 2 Preparation of Ti by Cumulative Rolling of AlC Particles 2 AlC particle reinforced copper matrix composite material is taken as an example, the size of oxygen-free pure copper plate is 200mm×25mm×1mm, Ti 2 The size of AlC particles is 100-200nm. The Ti 2 The preparation method of AlC particle reinforced copper matrix composite material is:

[0045] Step 1: Add 0.45g of Ti 2 Put the AlC particles into the mixed solution of 200ml alcohol and acetone and disperse at high speed for 30min to make Ti 2 AlC particle suspension;

[0046] Step 2: Perform surface treatment on the fully annealed oxygen-free pure copper plate to remove surface oil and oxide film;

[0047] Step 3: Put half of the dispersed Ti 2 The AlC particle suspension is evenly sprayed on the surface of the copper plate, and then the two copper plates are superimposed, fastened, rolled, cut in half, repeat the above process, and add Ti 2 AlC particles, carry out 2 ...

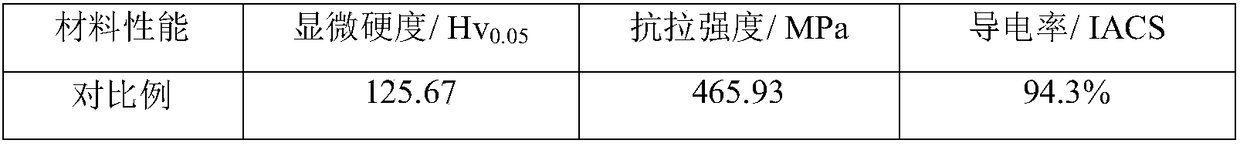

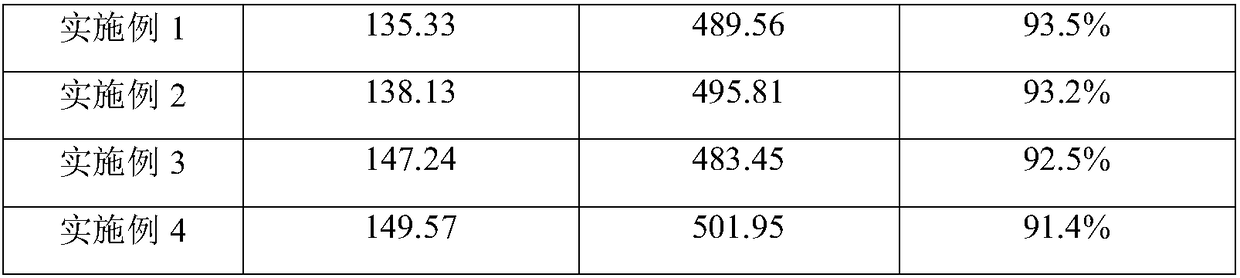

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com