A kind of preparation method of non-or low magnetic, cubic texture ni-w alloy composite substrate

A cubic texture and composite baseband technology, which is applied in the field of preparation of cubic textured nickel-based alloy composite basebands for high-temperature coated superconductors, can solve the problems of high cubic texture, non-magnetism, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

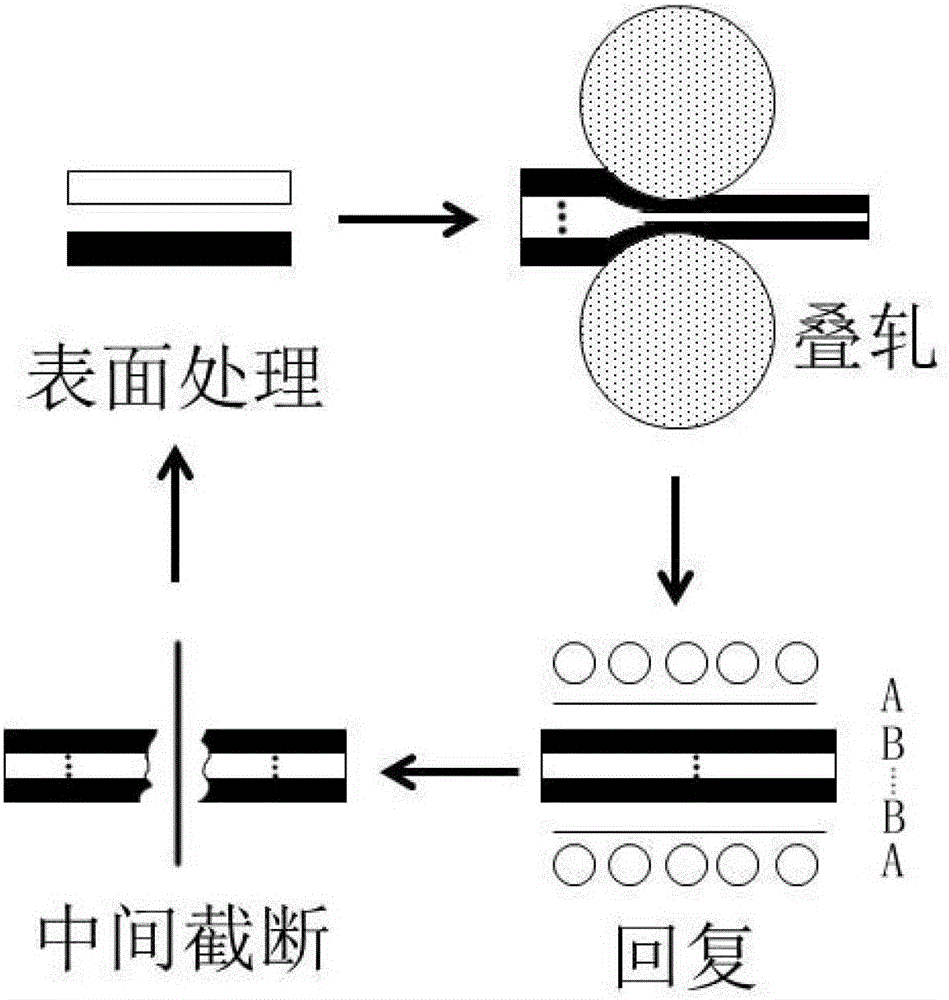

Method used

Image

Examples

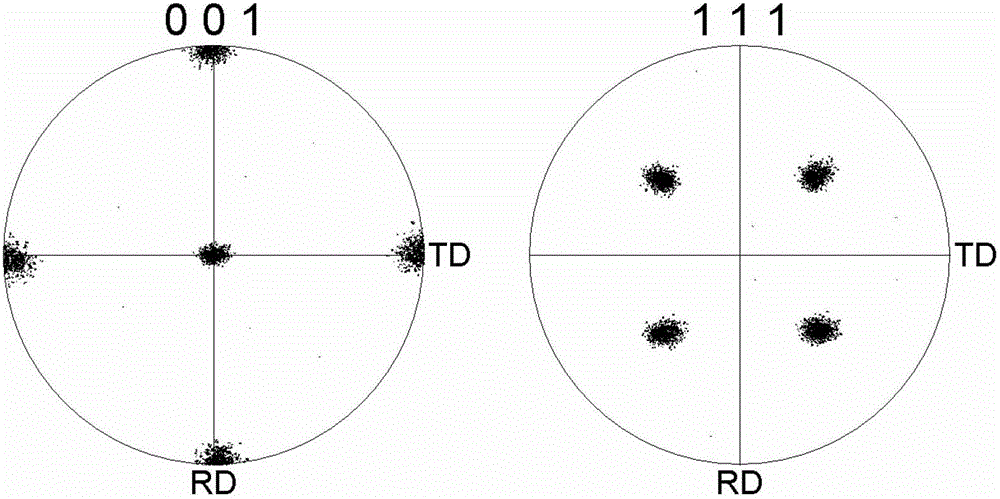

Embodiment 1

[0023] The Ni powder and W powder with a purity of 99.99% are respectively proportioned according to the ratio of the atomic percentage of W to 7% and 9.3%; Grind in a planetary high-energy ball mill with a hydrogen protective atmosphere until they are evenly mixed; put the mixed powders of two different proportions into an intermediate frequency vacuum induction furnace with a protective atmosphere for melting to obtain two Ni-W alloys with different W contents Ingot casting; then two kinds of Ni-W alloy ingots are obtained through hot forging and hot rolling; two initial ingots with the same size and a thickness of 1mm are obtained by wire cutting; The ingot was cold-rolled to 0.5mm, the deformation of each pass was controlled at 5%, and the total deformation was 50%, so as to obtain two cold-rolled ingots with the same thickness; the Ni-W alloy ingot with low W content after cold rolling was recorded as is A, and the Ni-W alloy ingot with high W content is denoted as B; the...

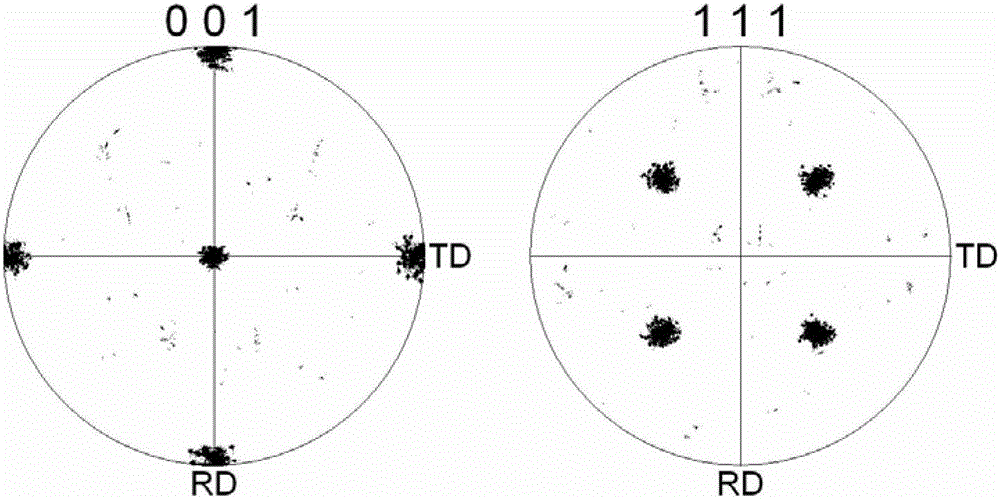

Embodiment 2

[0025] Ni powder and W powder with a purity of 99.99% were proportioned according to the ratio of W atomic percentage of 9.3% and 12% respectively; Grind in a planetary high-energy ball mill with a hydrogen protective atmosphere until they are evenly mixed; put the mixed powders of two different proportions into an intermediate frequency vacuum induction furnace with a protective atmosphere for melting to obtain two Ni-W alloys with different W contents Ingot casting; then two kinds of Ni-W alloy ingots are obtained through hot forging and hot rolling; two initial ingots with the same size and a thickness of 2mm are obtained by wire cutting; The ingot is cold-rolled to 1 mm, the deformation of each pass is controlled at 9%, and the total deformation is 50%, so as to obtain two cold-rolled ingots with the same thickness; the Ni-W alloy ingot with low W content after cold rolling is recorded as A, the Ni-W alloy ingot with high W content is denoted as B; the contact surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com