Composite board prepared by accumulative roll bonding of aluminum plates and titanium plates and preparation method of composite board

A composite plate, cumulative stack rolling technology, which is applied in the field of composite metal materials, can solve the problems of unsatisfactory bonding strength and mechanical properties of composite plates, harsh process conditions, etc., and achieve the effect of low cost, good bonding interface, and simple process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

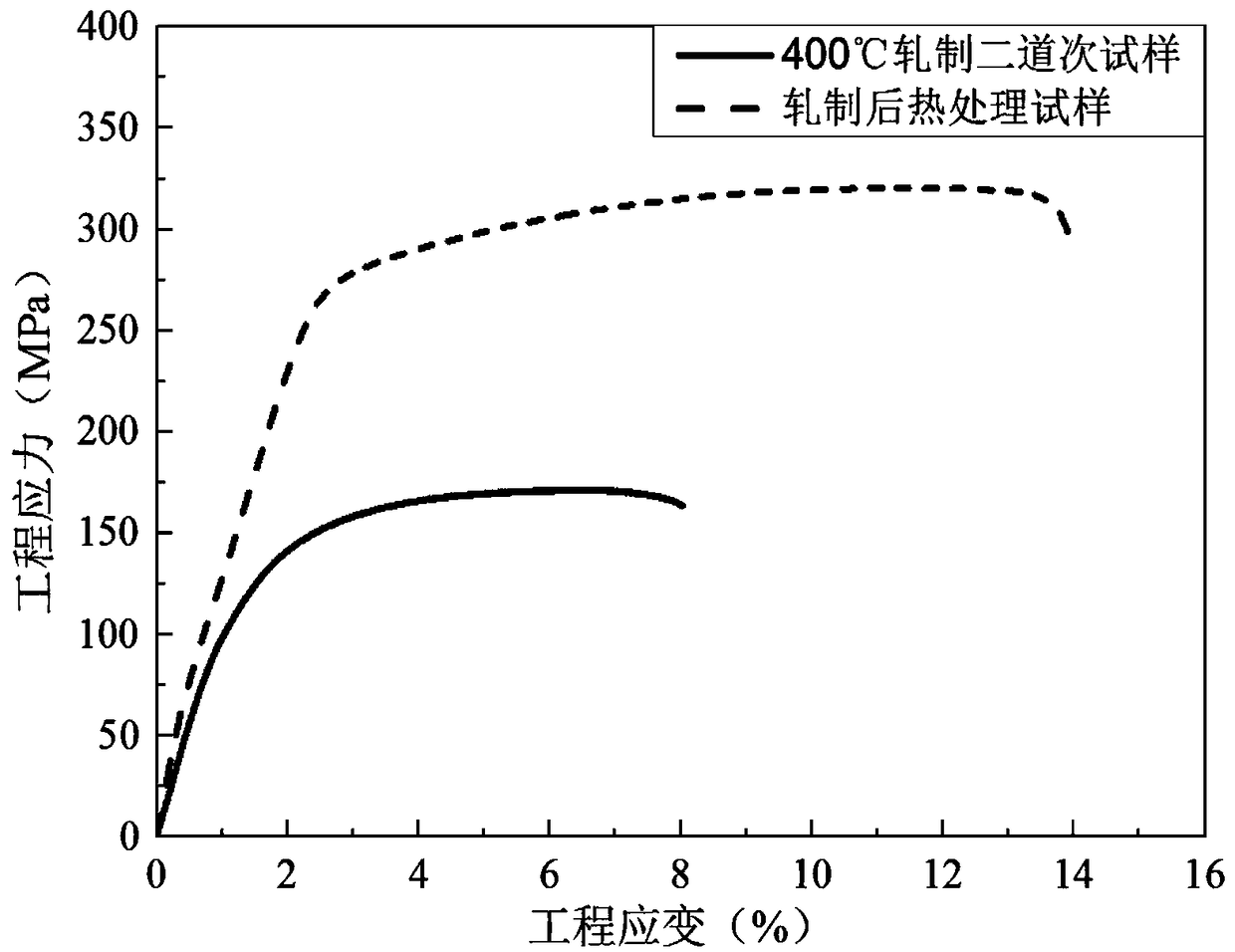

Embodiment 1

[0037] Cut the aluminum alloy plate with a thickness of 2mm and the titanium plate with a thickness of 0.2mm into 200mm×150mm (length×width), and clean the aluminum alloy plate with 5% NaOH solution in an ultrasonic instrument for 5mim at 50°C. At room temperature, use 3% HF+7% HNO 3 Solution Place the titanium plate in an ultrasonic instrument to clean it for 5 minutes, then rinse the plate with running water and alcohol in sequence and dry it; clean the surface of the plate with a stainless steel wire brush with a diameter of 0.2mm, and then clean the plate with alcohol again and dry it.

[0038]Stack the plates after surface treatment in the order of aluminum-titanium-aluminum-titanium-aluminum, punch holes in the four corners of the plates and bind and fix them with 1mm aluminum alloy filaments; put the accumulated plates into the resistance furnace for pre-rolling Preheating, the temperature is 400°C, and the holding time is 20 minutes; put the accumulated plate after pre...

Embodiment 2

[0043] Cut the aluminum alloy plate with a thickness of 2mm and the titanium plate with a thickness of 0.2mm into 150mm×150mm (length×width), and clean the aluminum alloy plate with 5% NaOH solution in an ultrasonic instrument for 5mim at 50°C. At room temperature, use 3% HF+7% HNO 3 Solution Place the titanium plate in an ultrasonic instrument to clean it for 5 minutes, then rinse the plate with running water and alcohol in sequence and dry it; clean the surface of the plate with a stainless steel wire brush with a diameter of 0.2mm, and then clean the plate with alcohol again and dry it.

[0044] Stack the plates after surface treatment in the order of aluminum-titanium-aluminum-titanium-aluminum, punch holes in the four corners of the plates and bind and fix them with 1mm aluminum alloy filaments; put the accumulated plates into the resistance furnace for pre-rolling Preheating, the temperature is 500°C, and the holding time is 10 minutes; put the accumulated plate after pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com