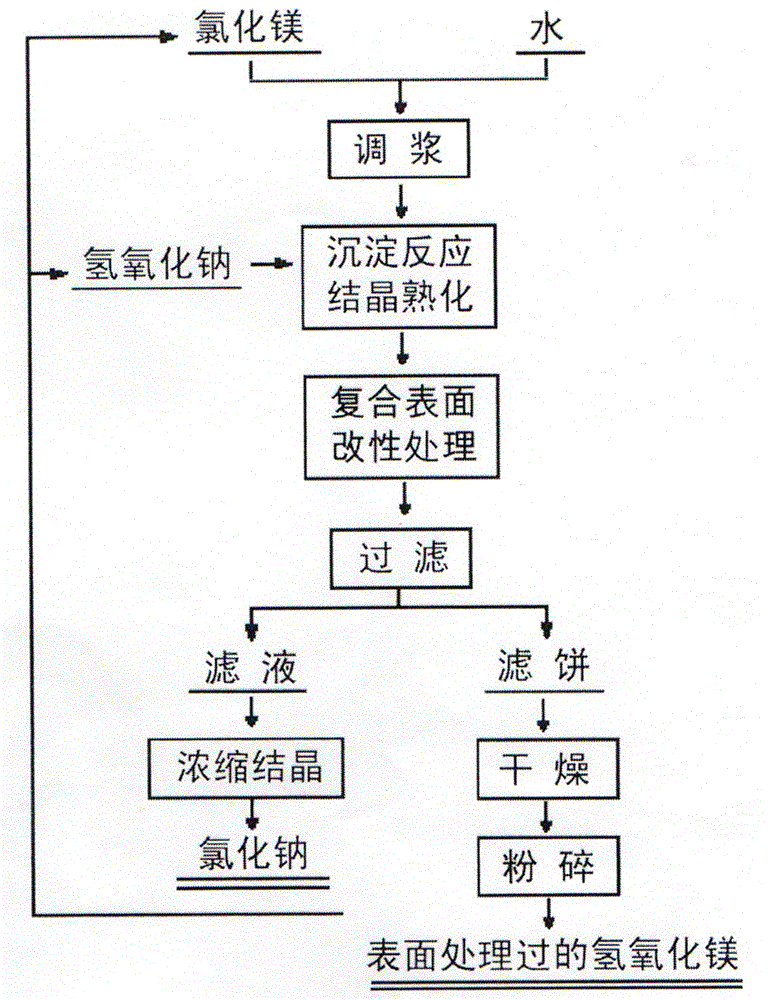

Method for preparing magnesium hydrate fire retardant through surface modification treatment by using composite wet method

A magnesium hydroxide and surface modification technology, which is applied in magnesium hydroxide, dyeing low molecular organic compound treatment, fibrous fillers, etc., can solve the problems of large equipment investment and high energy consumption in the process, and achieve low cost and good dispersion , the effect of great market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

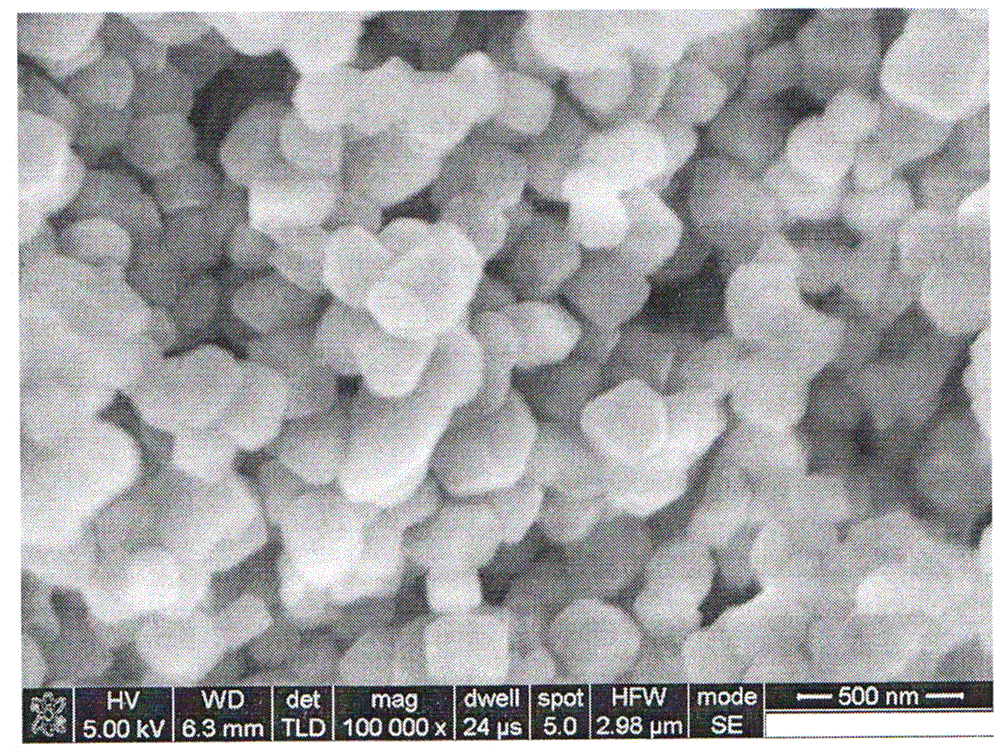

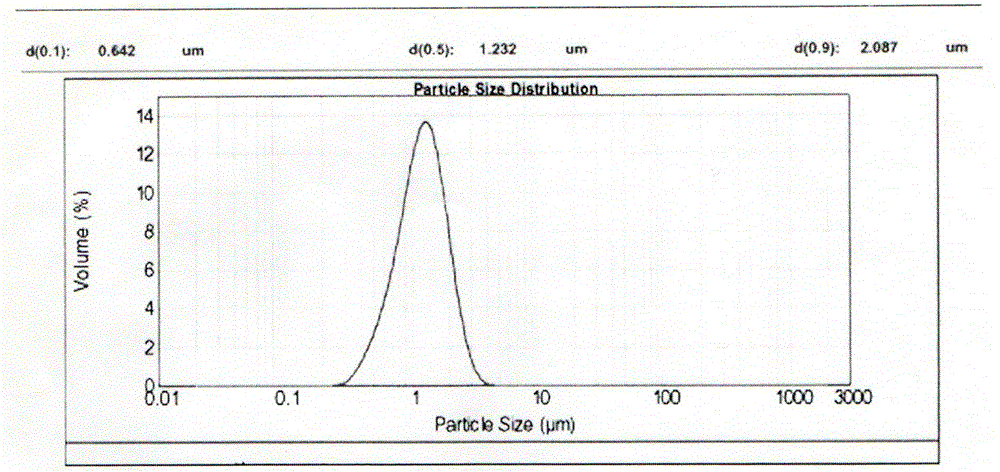

Embodiment 1

[0045] Take a certain amount of magnesium chloride hydrate and dissolve it in distilled water, the concentration of the substance is controlled at 1.0mol / L, take a certain amount of sodium hydroxide and dissolve it in distilled water, the concentration of the substance is controlled at 1.0mol / L, and stir it vigorously Under the action of the alkali solution, the alkali solution is added to the magnesium chloride solution, the pH value is controlled at 10.0, and the magnesium hydroxide precipitate is obtained. The slurry is heated to 60°C and kept for 60min to obtain a mature slurry, and the slurry is continued to be heated to 75°C. Coating modification treatment. At the same time, weigh 3.5% (relative to dry basis magnesium hydroxide, the same below) fatty acid and 10% sodium hydroxide (relative to the amount of fatty acid, the same below), and saponify at 80°C for 10 minutes to form a 5% saponified solution , while adding 1.5% hyperdispersant (based on dry magnesium hydroxide...

Embodiment 2

[0047] Take a certain amount of magnesium chloride hydrate and dissolve it in distilled water, the concentration of the substance is controlled at 1.0mol / L, take a certain amount of sodium hydroxide and dissolve it in distilled water, the concentration of the substance is controlled at 1.0mol / L, and stir it vigorously Under the action of the alkali solution, the alkali solution is added to the magnesium chloride solution, the pH value is controlled at 10.0, and the magnesium hydroxide precipitate is obtained. The slurry is heated to 60°C and kept for 60min to obtain a mature slurry, and the slurry is continued to be heated to 75°C. Coating modification treatment. At the same time, weigh 3.5% fatty acid and 10% sodium hydroxide, and saponify at 80°C for 10 minutes to form a 5% saponified liquid, and add 2.5% hyperdispersant at the same time. Add the prepared saponification solution into the slurry, and stir for modification for 60 minutes. Then filter, wash, dry, pulverize and...

Embodiment 3

[0049] Take a certain amount of magnesium chloride hydrate and dissolve it in distilled water. The concentration of the substance is controlled at 2.0mol / L. Take a certain amount of sodium hydroxide and dissolve it in distilled water. The concentration of the substance is controlled at 2.0mol / L. Under the action of the alkali solution, the alkali solution is added to the magnesium chloride solution, the pH value is controlled at 10.5, and the magnesium hydroxide precipitate is obtained. The slurry is heated to 60°C and kept for 60min to obtain a mature slurry, and the slurry is continued to be heated to 80°C. Coating modification treatment. At the same time, 4.0% fatty acid and 15% sodium hydroxide were weighed, and saponified at 80°C for 10 minutes to form a 10% saponified liquid, and 2.0% hyperdispersant was added at the same time. Add the prepared saponification solution into the slurry, and stir for modification for 60 minutes. Then filter, wash, dry, pulverize and classi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com