Composite metal lithium negative electrode and preparation method thereof

A composite metal, lithium negative electrode technology, applied in battery electrodes, structural parts, electrical components and other directions, can solve the problems of graphene oxide sheets that cannot be continuously produced, complex processes, no significance and value for amplification and practical application, etc. Solving the problem of lithium dendrite growth, uniform distribution, and alleviating the effect of negative electrode volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

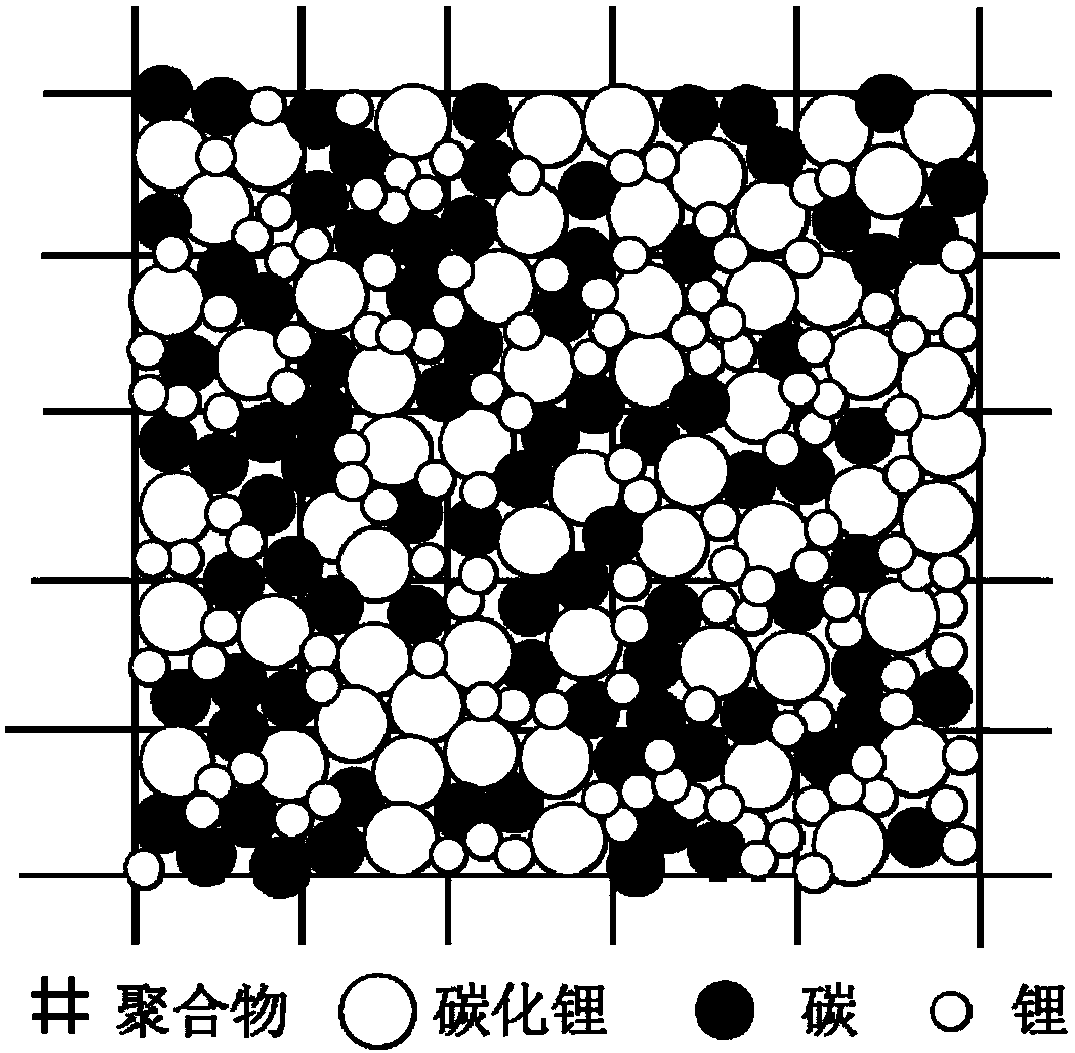

[0023] The polymer content in the composite metal lithium negative electrode is 2%, the nano-scale carbon material content is 25%, and the lithium metal content is 73%.

[0024] The composite metal lithium negative electrode is obtained by accumulative rolling method. The specific method is: using the cohesiveness of the polymer PTFE, rolling by the metal rolling method, and the deformation of the lower pressure is 10% to 50%, to obtain a three-dimensional rolling after one rolling Network polymer; the carbon material is spread on the surface of the three-dimensional network polymer, and then rolled, and the compression deformation is 20% to 50%, and the carbon is filled into the three-dimensional network structure to obtain a secondary structure filled with carbon; the metal Lithium is tiled on the surface of the secondary structure, and then rolled, with a deformation of 20% to 50% under pressure, a part of the metal lithium is embedded in the carbon material, and a part of t...

Embodiment 2

[0027] The polymer content in the composite metal lithium negative electrode is 10%, the nano-scale carbon material content is 50%, and the lithium metal content is 40%.

[0028] The composite metal lithium negative electrode was obtained by accumulative rolling method, and the specific method was the same as in Example 1.

Embodiment 3

[0030] The polymer content in the composite metal lithium negative electrode is 20%, the nano-scale carbon material content is 30%, and the lithium metal content is 50%.

[0031] The composite metal lithium negative electrode was obtained by accumulative rolling method, and the specific method was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com