A method for improving the purification efficiency of copper electrolyte

A technology of purification efficiency and copper electrolyte, which is applied in the field of electrolytic copper, can solve the problems of ketone-acid imbalance, easy precipitation of arsine, and generation of a large amount of black copper powder, so as to maintain the balance of keto-acid, speed up the reaction rate, and reduce acid The effect of fog formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The ion concentrations of Cu, As, Sb and Bi in the original electrolyte were 40 g / L, 0.10 g / L, 0.9 g / L and 0.5 g / L in sequence.

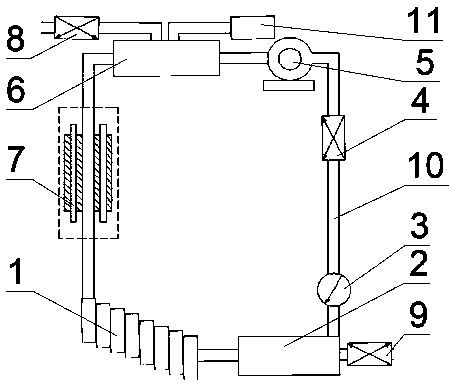

[0026] Step 1. Apply a magnetic field to the pipeline 10 of the electrolysis circulation system of the continuous electrolysis series stepped electrolytic cell, set the magnetic induction intensity of the magnetic field to 1T, turn on the circulation pump 5, and adjust and set the electrolyte through the flow meter 3 and the control valve 4 The flow rate is 0.2m / s, and the electrolyte is fully magnetized for 30 minutes;

[0027] Step 2: Turn on the power supply of the stepped electrolytic cell 1, set the temperature of the heating device 11 to 45°C, the current to 10000~12000A, the pole distance to 130mm, the lead anode to 1050×940×12mm, and the starting plate to 1030×960× 0.75mm, the number of cathodes in each tank is 37 pieces, and the number of anodes is 38 pieces. Under this condition, electrowinning is carried out to remove copper and im...

Embodiment 2

[0030] The ion concentrations of Cu, As, Sb and Bi in the original electrolyte were 50 g / L, 0.15 g / L, 2.3 g / L and 1.7 g / L in sequence.

[0031] Step 1. Apply a magnetic field to the pipeline 10 of the electrolytic liquid circulation system of the continuous electrowinning series stepped electrolytic cell, set the magnetic induction intensity of the magnetic field to 2T, turn on the circulating pump 5, and adjust and set the electrolyte through the flow meter 3 and the control valve 4 The flow rate is 0.5m / s, and the electrolyte is fully magnetized for 50min;

[0032] Step 2. Turn on the power supply of the stepped electrolytic cell 1, set the temperature of the heating device 11 to 50°C, the current to 10000~12000A, the pole distance to 130mm, the lead anode to 1050×940×12mm, and the starting plate to 1030×960× 0.75mm, the number of cathodes per cell is 37, and the number of anodes is 38. Under this condition, electrowinning is performed to remove copper and impurities. During...

Embodiment 3

[0035] The ion concentrations of Cu, As, Sb and Bi in the original electrolyte were 30 g / L, 0.9 g / L, 1.5 g / L and 1.1 g / L in sequence.

[0036] Step 1. Apply a magnetic field to the pipeline 10 of the electrolytic liquid circulation system of the continuous electrowinning series of stepped electrolytic cells, set the magnetic induction intensity of the magnetic field to 2.5T, turn on the circulating pump 5, and adjust the electrolysis through the flow meter 3 and the control valve 4 The flow rate of the liquid is 0.8m / s, and the electrolyte is fully magnetized for 60 minutes;

[0037] Step 2: Turn on the power supply of the stepped electrolytic cell 1, set the temperature of the heating device 11 to 50°C, the current to 10000~12000A, the pole distance to 130mm, the lead anode to 1050×940×12mm, and the starting plate to 1030×960× 0.75mm, the number of cathodes per cell is 37, and the number of anodes is 38. Under this condition, electrowinning is performed to remove copper and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com