Inverted electrolytic polishing device and electrolytic polishing equipment thereof

An electrolytic polishing and inversion technology, applied in the direction of electrolytic process, electrolytic components, etc., can solve problems such as poor effect, poor electrolysis of stainless steel containers, and low production efficiency, so as to improve the degree of automation and production efficiency, and realize the degree of infiltration and contact , the effect of preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

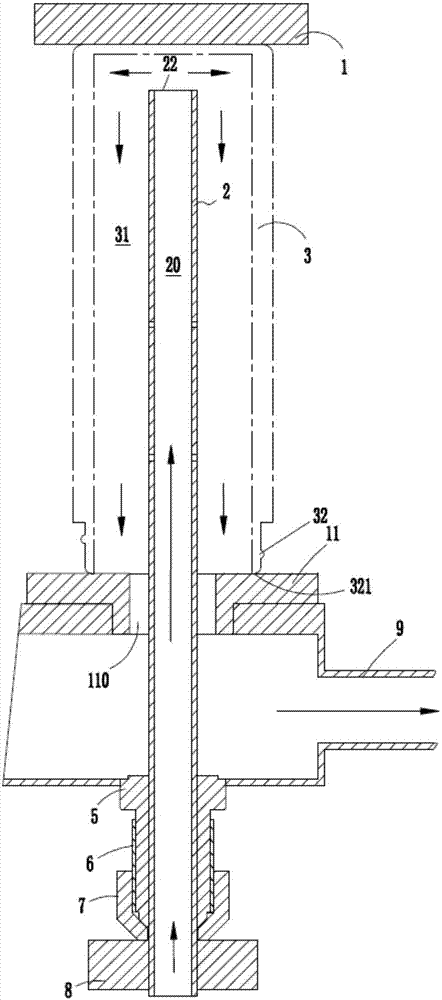

[0031] ginseng figure 1 , Figure 4 and Figure 5 The first specific implementation of an inverted electrolytic polishing device is shown.

[0032] In this embodiment, the workpiece 3 is inverted and extended into the inner cavity 31 of the workpiece 3 through the electrolytic rod 2 , and the electrolyte 81 is injected. Electrolyte 81 ginseng figure 1 In the direction shown by the middle arrow, it flows through the columnar channel 20 formed by the electrolytic rod 2 in a bottom-up manner, and flows out of the electrolytic rod 2 from the opening 22 at the top, and finally fills the workpiece 3 Internal cavity 31 .

[0033] During electropolishing, the workpiece 3 is located between the anode 1 and the cathode 8 . The anode 1 can be moved up and down by the electrode lifting mechanism 40 as a whole, so that both ends of the workpiece 3 are clamped by the anode 1 and the cathode 8 respectively. It should be noted that, in this application, the workpiece 3 is a cup-shaped o...

Embodiment 2

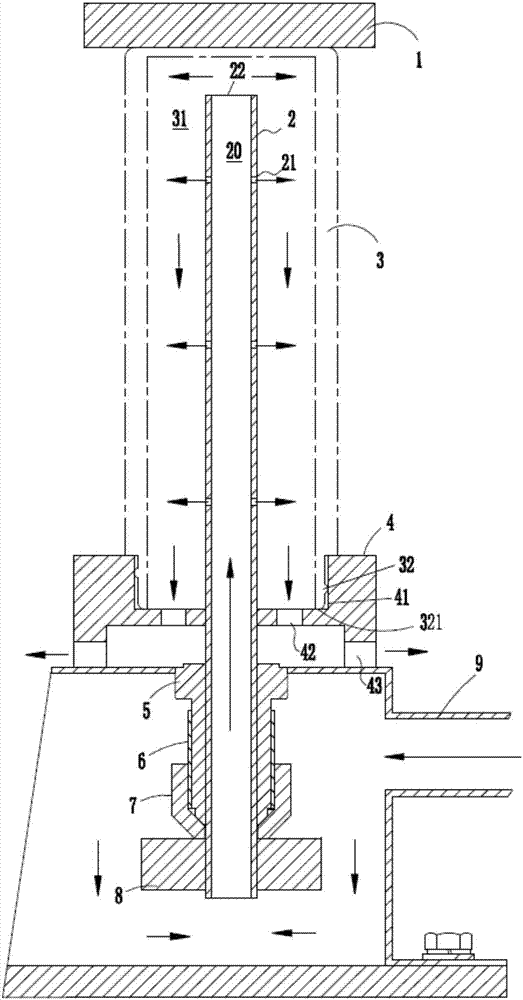

[0042] ginseng image 3 , Figure 4 and Figure 5 The second specific implementation of an inverted electrolytic polishing device is shown.

[0043] The main difference between this embodiment and the inverted electrolytic polishing device disclosed in Embodiment 1 is that, in this embodiment, a number of injection holes 21 are opened on the side wall of the electrolytic rod 2 . At the same time, the electrolytic rod 2 in this embodiment can be linear or spiral, and a number of injection holes 21 are provided on the side wall of the electrolytic rod 2 .

[0044] In this embodiment, the function of the spray hole 21 is: when the electrolyte 81 flows upward in the columnar channel 20 formed by the electrolytic rod 2, part of the electrolyte 81 can be sprayed horizontally, so that the horizontal The electrolyte solution 81 sprayed in a circular shape strips off the remaining air bubbles attached to the inner wall surface of the workpiece 3, and takes away from the inner cavity...

Embodiment 3

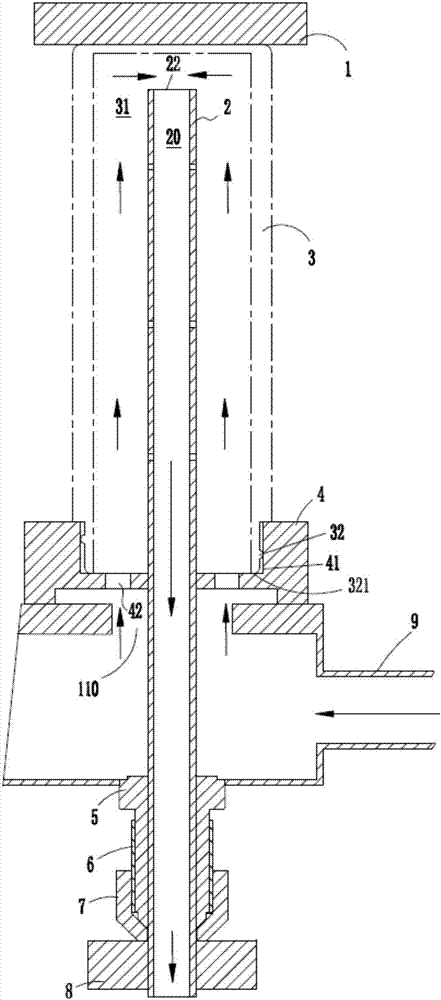

[0047] ginseng figure 2 , Figure 4 and Figure 5 The third embodiment of an inverted electrolytic polishing device is shown.

[0048] The main difference between this embodiment and the inverted electrolytic polishing device disclosed in Embodiment 1 and Embodiment 2 is that, in this embodiment, a disc-shaped support 4 is provided between the mouth 32 of the workpiece 3 and the return pipe 9 A plurality of first through holes 42 are provided along the longitudinal direction of the bracket 4 , and the first through holes 42 are used to establish a circulation path between the internal cavity 31 of the workpiece 3 and the return pipe 9 .

[0049] Specifically, see figure 2 As shown, in this embodiment, the bracket 4 is in the shape of a disc, and a circular concave portion 41 is formed on the top of the bracket 4, and the mouth 32 of the workpiece is accommodated and clamped by the concave portion 41. The bottom surface of the ring formed by the bottom edge 321 of the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com