Multipurpose high-strength integrated solid carbon fiber inhaul cable and preparation method thereof

A carbon fiber, high-strength technology, used in buildings, bridges, bridge parts, etc., can solve the problems of tendons being easily damaged, easily damaged by bending, and not consistent in corrosion resistance, and achieve controllability and manufacturing process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing the multi-purpose high-strength integrated solid carbon fiber cable as described above comprises the following steps:

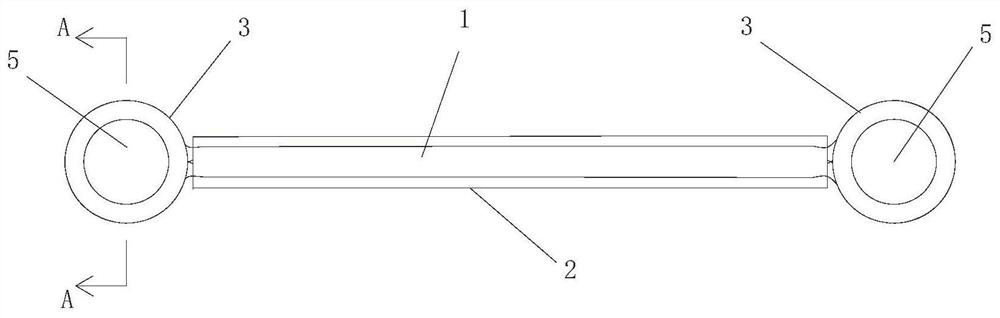

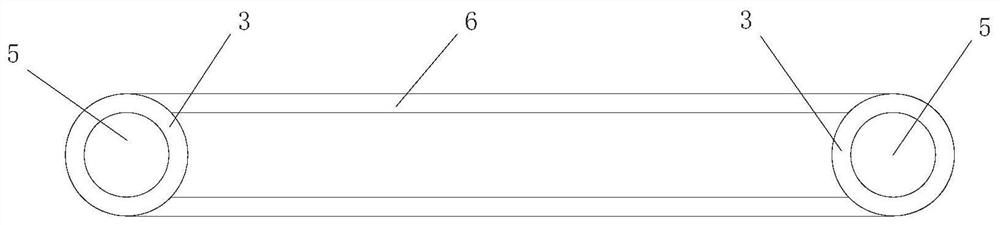

[0047] (1) Fix the two alloy joints 3 at relative intervals, and then wind the prepreg carbon fiber on the two alloy joints 3 to form an annular prepreg carbon fiber winding 6 and the alloy joint 3 is located in the radial direction of the prepreg carbon fiber winding 6 both ends of

[0048] (2) Move at least one of the two alloy joints 3 to tension the prepreg carbon fiber winding 6 to the preset length of the multi-purpose high-strength integrated solid carbon fiber cable, then control the alloy joint 3 and twist the prepreg carbon fiber Winding 6, so that the pre-impregnated carbon fiber between the two alloy joints 3 is twisted to form the cable body 101, the pre-impregnated carbon fiber at the alloy joint 3 forms the closed ring 102, and then compresses the cable body from the radial direction 1, forming a solid cable body ...

Embodiment 1

[0055] A high-strength cable for sports venues

[0056] Cable requirements: load 490 tons (considering safety factor 2.2-2.5), length 18.5 meters

[0057] 1. Raw material preparation: T700SC 24K carbon fiber prepreg tape is used for prepreg carbon fiber, the mass ratio of carbon fiber bundle to prepreg resin glue is set to 7:3, and the width of prepreg carbon fiber is 35mm.

[0058] Several fiberglass tapes

[0059] Several ceramic coatings

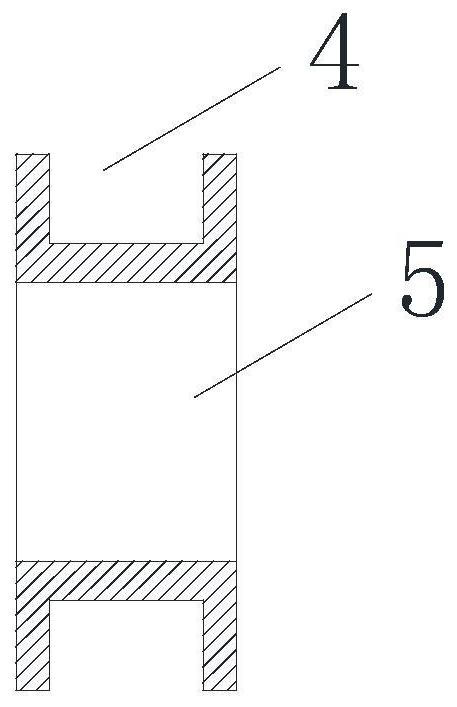

[0060] There are 2 titanium alloy circular joints with an outer diameter of 150mm and an inner diameter of 50mm. The groove 4 is 30mm deep and 50mm wide, and the wall thicknesses on both sides of the groove are 2.5mm respectively.

[0061] 2. The distance between two titanium alloy circular joints is set to be 17.6 meters, and the prepreg carbon fiber is wound 16 times with two alloy joints 3 (titanium alloy circular joints in this embodiment) as supports to form prepreg carbon fiber Winding 6.

[0062] 3. Move the titanium alloy circ...

Embodiment 2

[0074] A support cable for a car crane

[0075] Cable requirements: load 250 tons (safety factor 3.5 has been considered), length 14 meters

[0076] 1. Raw material preparation: T700SC carbon fiber 12K prepreg tape is used for prepreg carbon fiber. The mass ratio of carbon fiber bundles to prepreg resin glue is 7:3, and the width of prepreg carbon fiber is 25 mm.

[0077] Several fiberglass tapes

[0078] Several ceramic coatings

[0079] Two titanium alloy circular joints, with an outer diameter of 100 mm and an inner diameter of 40 mm, grooves 4 with a depth of 20 mm and a width of 35 mm, with wall thicknesses of 2.5 mm on both sides of the groove.

[0080] 2. The distance between two titanium alloy circular joints is set to be 13.5 meters, and the prepreg carbon fiber is wound 13 times with two alloy joints 3 (titanium alloy circular joints in this embodiment) as supports to form prepreg carbon fiber Winding 6.

[0081] 3. Move the titanium alloy circular joint at one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com