Halogen-free fire retardation long glass fiber reinforced PET composite material and preparation method thereof

A composite material and long glass fiber technology, applied in the field of halogen-free flame retardant long glass fiber reinforced PET composite material and its preparation, can solve the problem of serious decomposition of halogen-free flame retardant, and achieve the effect of solving serious decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

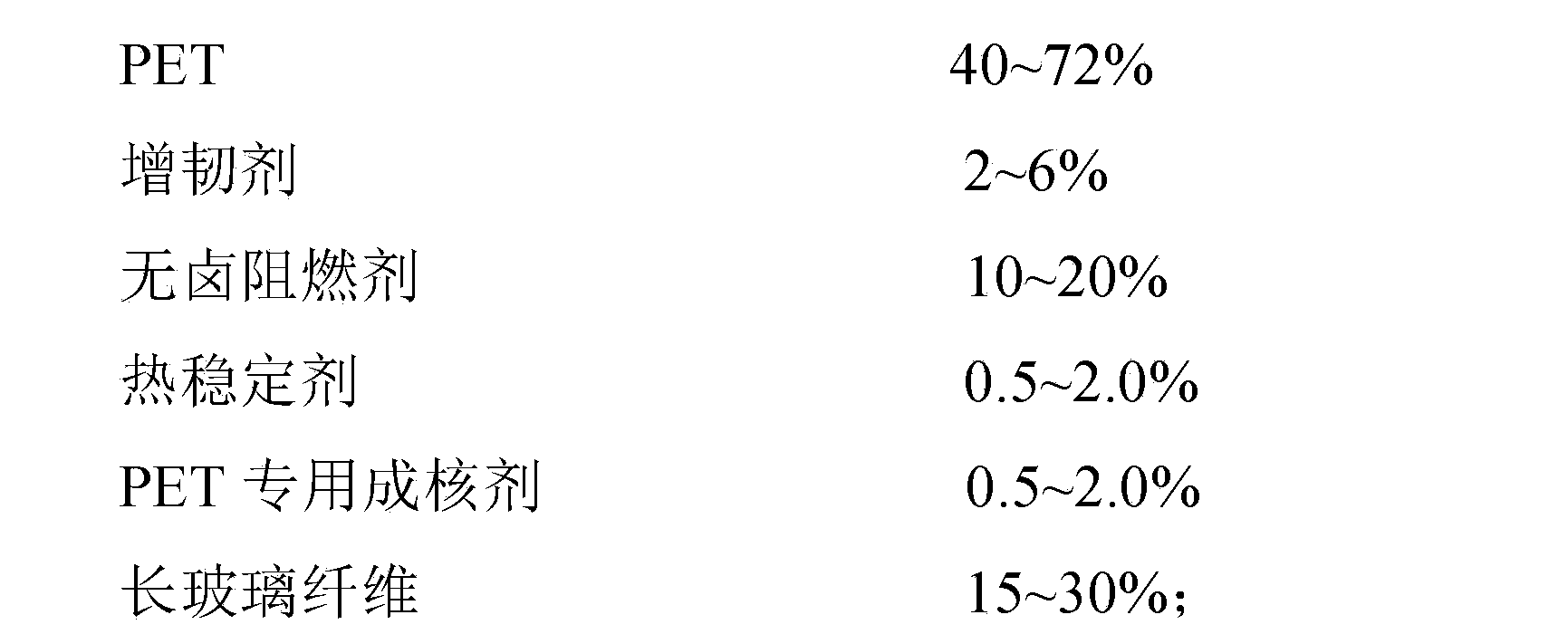

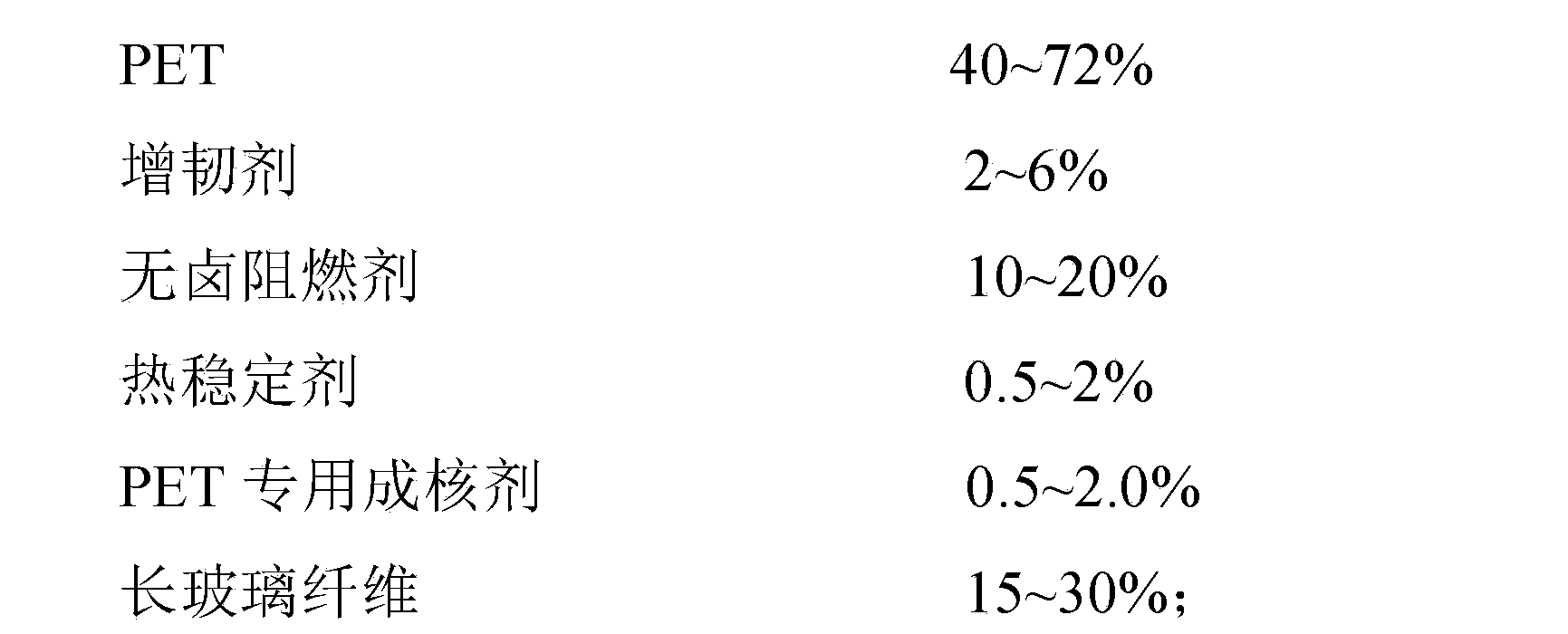

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Plasticize 15 kg of PET WK801 through a single-screw extruder with a length-to-diameter ratio of 20:1 and transport it to a high-temperature melt infiltration tank through a die. The temperature in the high-temperature melt infiltration tank is 320°C. And the length of the high temperature melt infiltration tank is 2m;

[0021] Step 2: Mix 57.0 kg of PET WK801, 2 kg of toughening agent EVA2825, 0.2 kg of phenolic heat stabilizer 1010, 0.3 kg of phosphite antioxidant 168, 0.2 kg of talcum powder, 0.3 kg of Surlyn 8920, and 10 kg of Klein The flame retardant OP 1311 is plasticized by a single-screw extruder with a length-to-diameter ratio of 20:1, and then transported to a low-temperature melt infiltration tank through a die. The temperature in the low-temperature melt infiltration tank is 275 ° C, and the low temperature The length of the melt infiltration tank is 1m;

[0022] Step 3: Pass 15 kg of continuous long glass fiber Tufrov 4585 produced by PPG through ...

Embodiment 2

[0026] Step 1: Plasticize 20 kg of PET WK821 through a single-screw extruder with an aspect ratio of 20:1 and transport it to a high-temperature melt infiltration tank through a die. The temperature in the high-temperature melt infiltration tank is set at 340°C , and the length of the high temperature melt infiltration tank is 2m;

[0027] Step 2: Mix 39 kg of PET WK821, 4 kg of toughening agent PTW, 0.5 kg of phenolic heat stabilizer 1010, 0.5 kg of phosphite antioxidant 627A, 0.5 kg of sodium benzoate, 0.5 kg of Aclyn 285, 15 kg of Klein Flame retardant OP 1312 is plasticized by a single-screw extruder with an aspect ratio of 20:1, and then transported to a low-temperature melt infiltration tank through a die. The temperature in the low-temperature melt infiltration tank is 280 ° C, and the low temperature The length of the melt infiltration tank is 1m;

[0028] Step 3: Pass 20 kg of continuous long glass fiber Tufrov 4585 produced by PPG through the high-temperature melt t...

Embodiment 3

[0032] Step 1: Plasticize 20 kg of PET CZ-318 through a single-screw extruder with a length-to-diameter ratio of 20:1 and transport it to a high-temperature melt infiltration tank through a die. The temperature in the high-temperature melt infiltration tank is 360 ℃, and the length of the high temperature melt infiltration tank is 2.5m;

[0033] The second step: 32 kg of PET CZ-318, 5 kg of toughening agent PTW, 0.8 kg of phenolic heat stabilizer 1010, 0.7 kg of phosphite antioxidant 627A, 0.7 kg of Surlyn 8920, 0.8 kg of Aclyn 285, 10 kg Klein flame retardant OP 1240, 5 kg of flame retardant MPP are plasticized by a single-screw extruder with a length-to-diameter ratio of 20:1, and then transported to a low-temperature melt infiltration tank through a die, and the low-temperature melt infiltration tank The temperature is set at 285°C, and the length of the low-temperature melt infiltration tank is 1.5m;

[0034] Step 3: Pass 25 kg of continuous long glass fiber Tufrov 4588 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com