Repairing method of large composite material shelter

A technology of composite materials and repair methods, applied in the field of repair of shelters, to achieve good effects, prolong service life, and improve fatigue strength and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

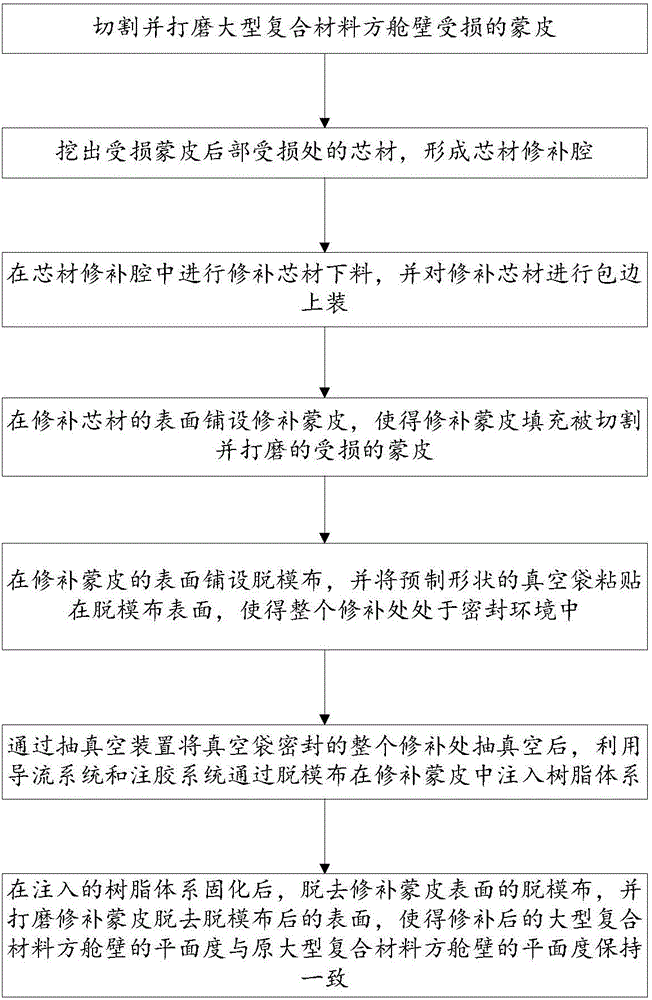

[0029] Such as figure 1 Shown, a kind of repair method of large-scale composite shelter, comprises the following steps,

[0030] Step 1, cutting and grinding the damaged skin of the large composite material square bulkhead;

[0031] Step 2, digging out the core material at the damaged part of the damaged skin to form a core material repair cavity;

[0032] Step 3, cutting the repair core material in the core material repair cavity, and wrapping and topping the repair core material;

[0033] Step 4, laying a repair skin on the surface of the repair core material, so that the repair skin fills the cut and polished damaged skin;

[0034] Step 5, laying a release cloth on the surface of the repaired skin, and pasting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com