Three-step pre-wetting method of through-silicon-via plating

A through-silicon via and pre-dipping technology, applied in the field of 3D packaging, can solve the problems of seed layer shedding, low efficiency, complex process, etc., and achieve the effect of improving efficiency, reducing cost and shortening process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

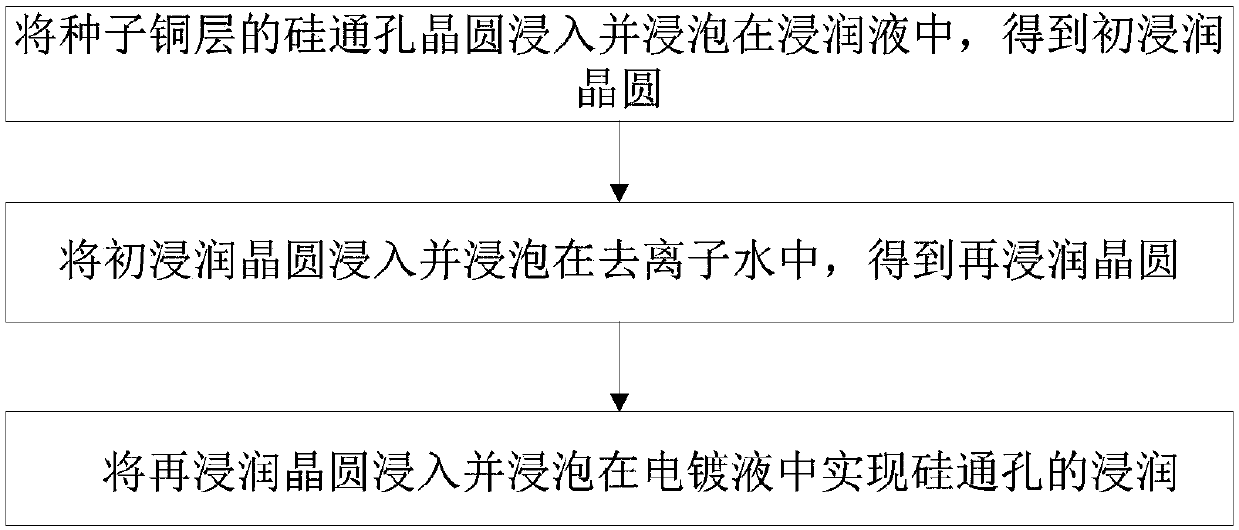

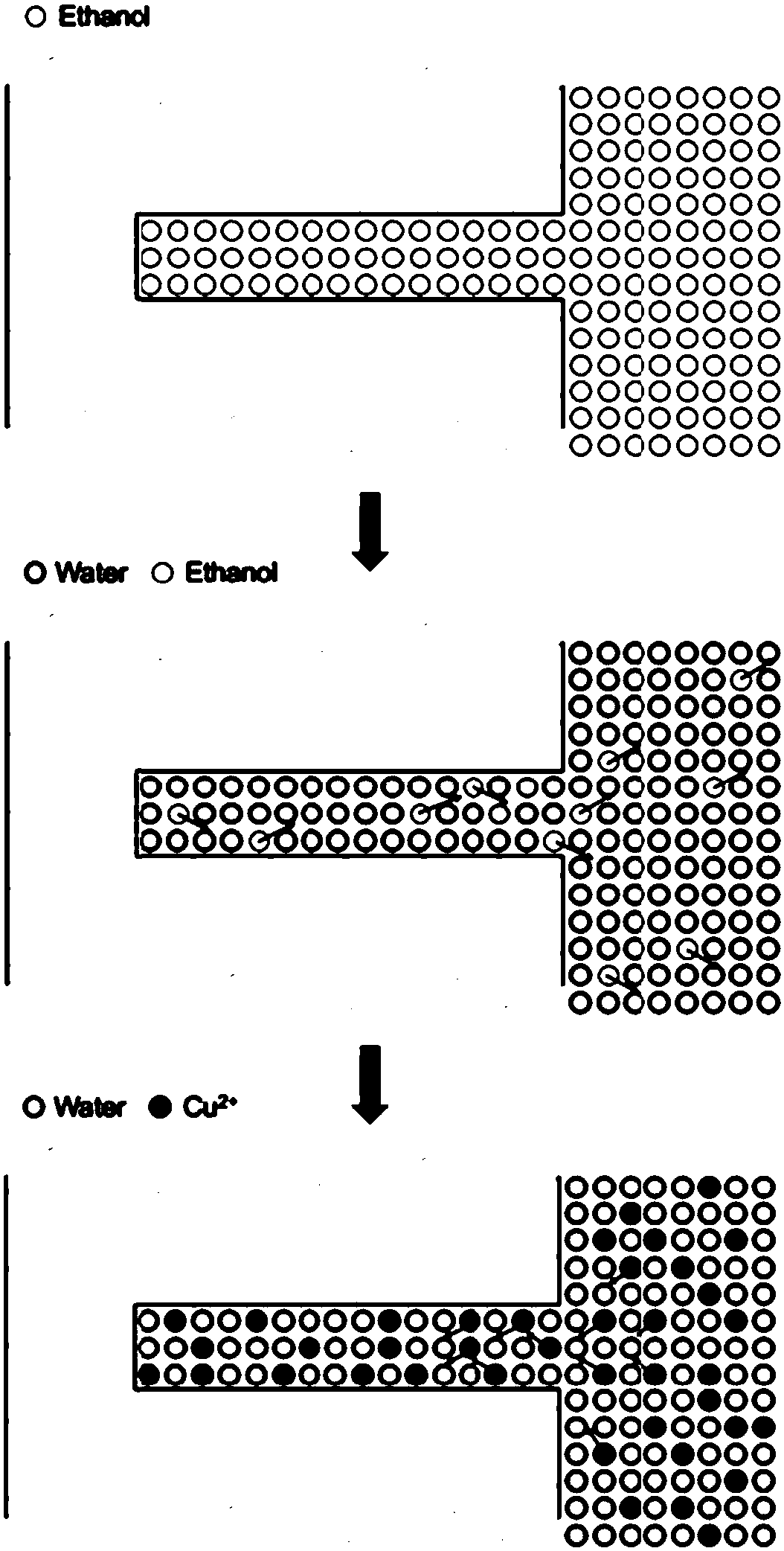

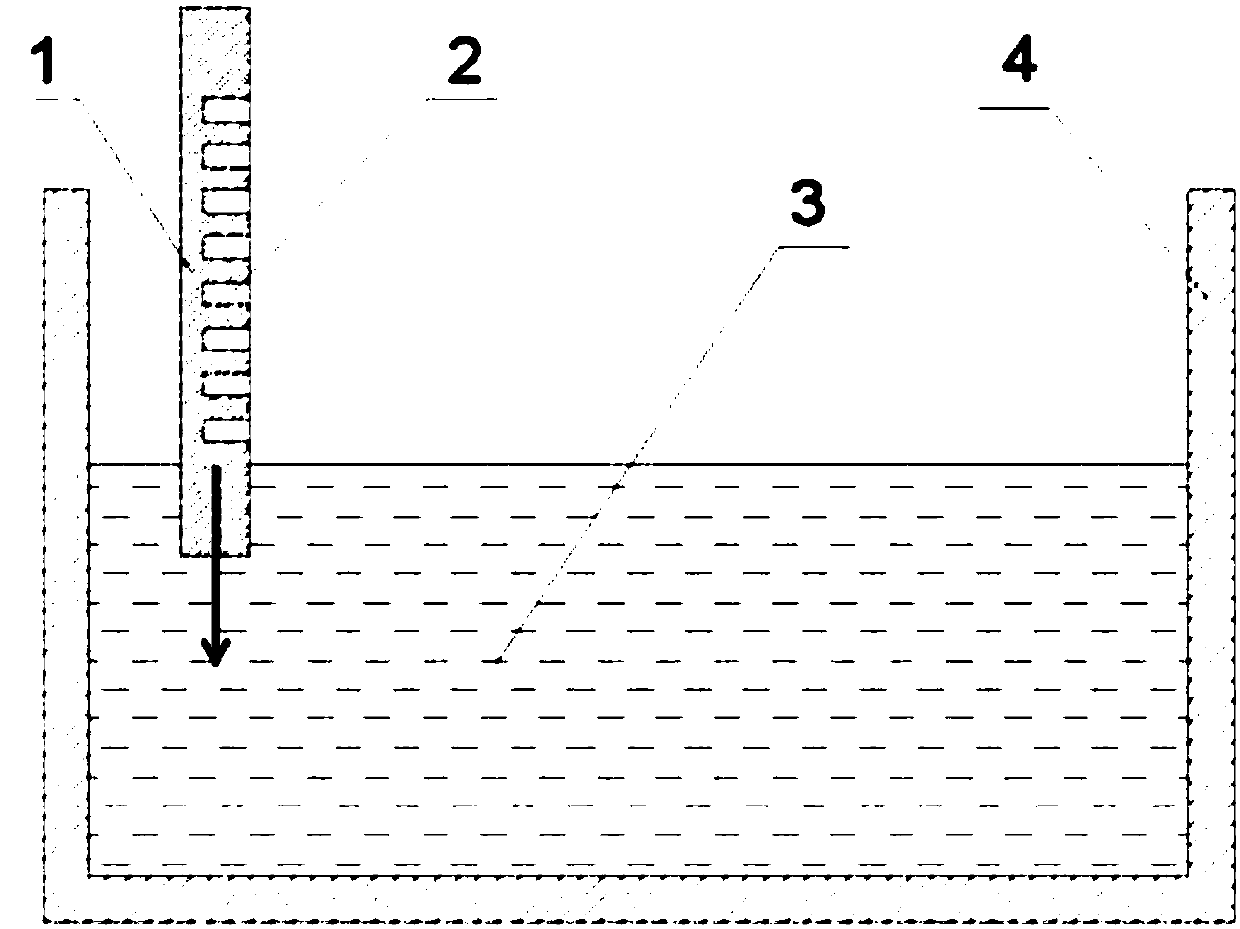

[0031] Such as figure 2 As shown, the TSV wafer of the seed copper layer is immersed vertically downward and immersed in the immersion solution, and the angle between the TSV wafer of the seed copper layer and the liquid surface of the immersion solution is 90°, as shown in image 3 As shown, the immersion speed of the TSV wafer with the seed copper layer is 5mm / s. When the TSV wafer with the seed copper layer is completely wetted, an incipient wetted wafer is obtained. Due to the high wetting property of ethanol to the seed copper (the contact angle is close to 0°), the ethanol will completely wet and fill the inside of the TSV. The TSVs have a pore diameter of 3 μm, a pore depth-to-diameter ratio of 15:1, and an immersion solution of absolute ethanol. Immerse the incipient wet wafer vertically downward and soak it in deionized water. Due to the miscibility of absolute ethanol and water in any ratio, the ethanol in the TSV will dissolve in the water, so that the deionized w...

Embodiment 2

[0033] Immerse the TSV wafer of the seed copper layer and soak it in the wetting solution. The angle between the TSV wafer of the seed copper layer and the liquid level of the immersion solution is 45°, such as Figure 4 As shown, the immersion speed of the TSV wafer with the seed copper layer is 5mm / s. When the TSV wafer with the seed copper layer is completely wetted, an incipient wetted wafer is obtained. Due to the high wetting property of ethanol to the seed copper (the contact angle is close to 0°), the ethanol will completely wet and fill the inside of the TSV. The TSVs have a pore diameter of 3 μm, a pore depth-to-diameter ratio of 15:1, and an immersion solution of absolute ethanol. Dip the incipient wet wafer into deionized water. Due to the miscibility of absolute ethanol and water in any ratio, the ethanol in the TSV will dissolve in the water, so that the deionized water can completely fill the TSV and clean the inside of the TSV. The included angle between the i...

Embodiment 3

[0035] Dip the TSV wafer of the seed copper layer vertically downwards and soak it in the immersion solution, the angle between the TSV wafer of the seed copper layer and the liquid level of the immersion solution is 0°, The immersion speed of the wafer is 5mm / s. When the TSV wafer of the seed copper layer is completely wetted, an incipient wetted wafer is obtained. Due to the high degree of wetting property (contact angle close to 0°) of the seed copper by ethanol, ethanol It will be possible to completely infiltrate and fill the interior of the TSV. The TSVs have a pore diameter of 3 μm, a pore depth-to-diameter ratio of 15:1, and an immersion solution of absolute ethanol. Immerse the incipient wet wafer vertically downward and soak it in deionized water. Due to the miscibility of absolute ethanol and water in any ratio, the ethanol in the TSV will dissolve in the water, so that the deionized water will completely fill the TSV, realizing the TSV Internal cleaning. The angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com