Water-soluble silicon steel sheet insulating paint and preparation method thereof

A silicon steel sheet and insulating varnish technology, which is applied in the direction of insulators, coatings, electrical components, etc., can solve the problems of poor paint film adhesion, low non-volatile content, poor storage stability, etc., and achieve uniform and stable storage. High, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

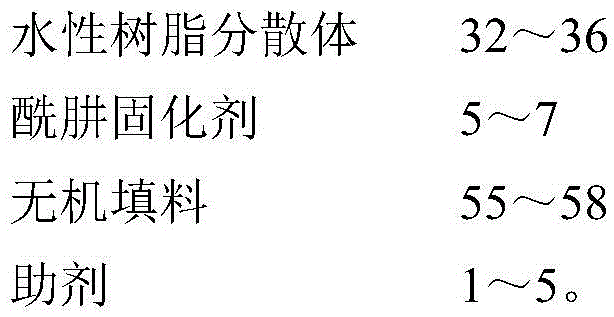

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 100g of 4,4'-diphenylmethane diisocyanate and 250g of polycaprolactone diol with a molecular weight of 1000 in 50g of N-methylpyrrolidone, and react at 60°C until the content of isocyanate group (-NCO) reaches a stable value to obtain Polyurethane prepolymer, denoted as PU-1.

[0023] Under the protection of nitrogen, mix 100g epoxy resin E51 and 60g polyurethane prepolymer PU-1 evenly, after reacting at 75°C for 3 hours, add isobutanol and 2% benzoyl peroxide, and dissolve 40g Add methacrylic acid and 56g butyl acrylate into the polyurethane modified epoxy resin system. After 0.5 hours of dripping, keep warm for 4.5 hours, cool down to 50°C, neutralize with ANP-95 to pH 9.1, add water , to obtain a polyurethane-modified aqueous epoxy resin dispersion with a non-volatile content of 46.12%.

[0024] Mix 36 parts of the above-mentioned polyurethane modified water-based epoxy dispersion, 5 parts of M-16, and 3 parts of additives evenly, and add 56 parts of compos...

Embodiment 2

[0026] Under the protection of nitrogen, mix 100g epoxy resin E51 and 48g polyurethane prepolymer PU-1 evenly, after reacting at 80°C for 2.5 hours, add isobutanol and 2% benzoyl peroxide, and dissolve 37g Add methacrylic acid and 51.8g butyl acrylate into the polyurethane modified epoxy resin system dropwise. After 0.5 hours of dripping, after 4 hours of heat preservation reaction, cool down to 50°C, neutralize with ANP-95 until the pH value is 8.4, add An appropriate amount of water was used to obtain a polyurethane-modified aqueous epoxy resin dispersion with a non-volatile content of 43.34%.

[0027] Mix 33 parts of the above-mentioned polyurethane modified water-based epoxy dispersion, 6 parts of M-16, and 4 parts of additives evenly, and add 57 parts of composite inorganic fillers to disperse evenly. The addition amount of wetting and dispersing agent SN-5027 is 2 parts.

Embodiment 3

[0029] Under the protection of nitrogen, mix 100g epoxy resin E51 and 75g polyurethane prepolymer PU-1 evenly, after reacting at 80°C for 3 hours, add isobutanol and 2% benzoyl peroxide, at 115°C, 43.75 1 g of methacrylic acid and 61.25 g of butyl acrylate were dropped into the polyurethane modified epoxy resin system. After 1 hour of dripping, after 4.5 hours of heat preservation reaction, the temperature was lowered to 50°C, and the pH value was neutralized to 8.9 with ANP-95. An appropriate amount of water was added to obtain a polyurethane-modified aqueous epoxy resin dispersion with a non-volatile content of 47.58%.

[0030] Mix 35.5 parts of the above-mentioned polyurethane modified water-based epoxy dispersion, 5.5 parts of M-16, and 3.5 parts of additives evenly, and add 55.5 parts of composite inorganic fillers to disperse evenly. The addition amount of wetting and dispersing agent SN-5027 is 1.5 parts.

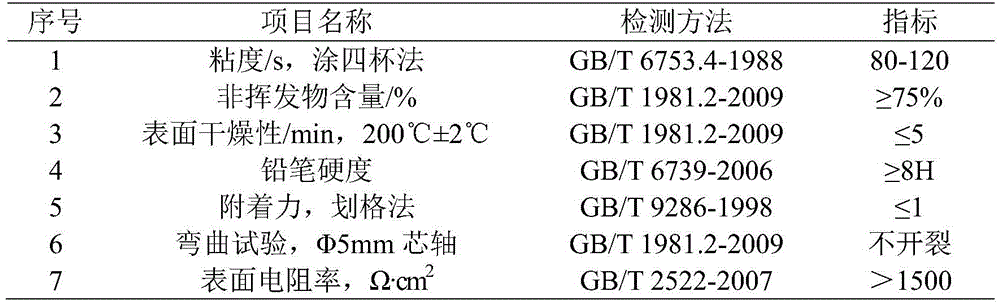

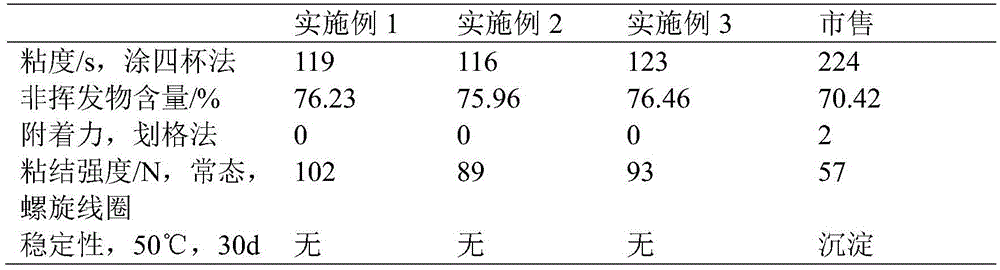

[0031] The properties of the silicon steel sheet paint prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com