Roll shaft channel device of double-block type sleeper production line

A channel device and production line technology, applied to auxiliary forming equipment, shock absorbers, ceramic molding machines, etc., can solve problems such as low construction safety factor, unguaranteed product quality and progress, frequent damage to roller shaft channels, etc., to achieve Improve the construction safety factor, save equipment maintenance funds and manpower costs, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

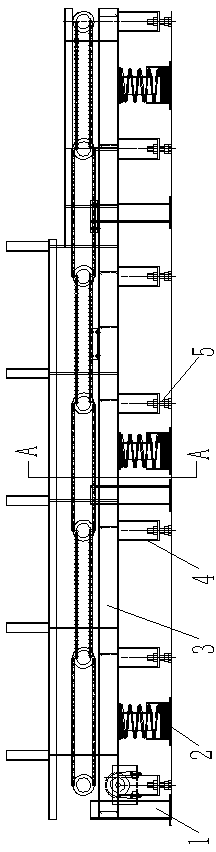

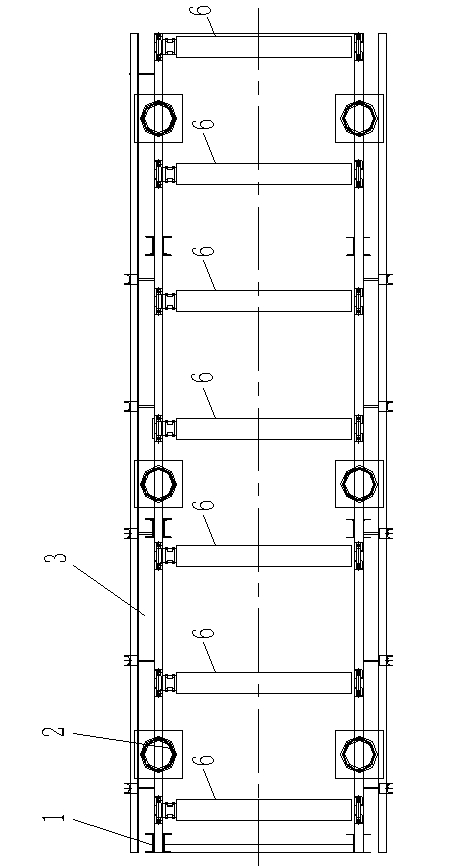

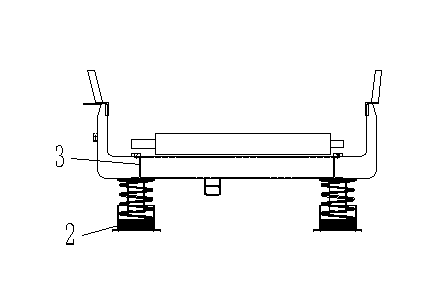

[0018] as attached Figure 1-5 As shown, a double-block sleeper production line roller channel device includes a roller channel frame 3, the roller channel frame 3 is a steel structure frame, and a number of roller shafts 6 are arranged on it, and each roller shaft 6 is driven by a motor through a chain transmission. The lower part of the roller channel frame 3 is provided with a number of brackets 4 fixedly connected to it. The lower part of the bracket 4 is connected to the ground through anchor bolts. The anchor bolts are provided with a reserved buffer area 5, and the bracket 4 can be mounted on the anchor bolts. Move up and down in the reserved buffer area 5. At least two elastic buffer devices 2 are provided on the lower part of the roller channel frame 3 , and at least two lateral limiting devices 1 are provided on both sides of the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com