Gas-catalytic, flameless and infrared-radiation hot air internal recycle drying unit module of passenger car

A technology of drying unit modules and hot air internal circulation, which is applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., which can solve the problems of low thermal efficiency, different, easy to affect the production progress, etc., to ensure the production progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

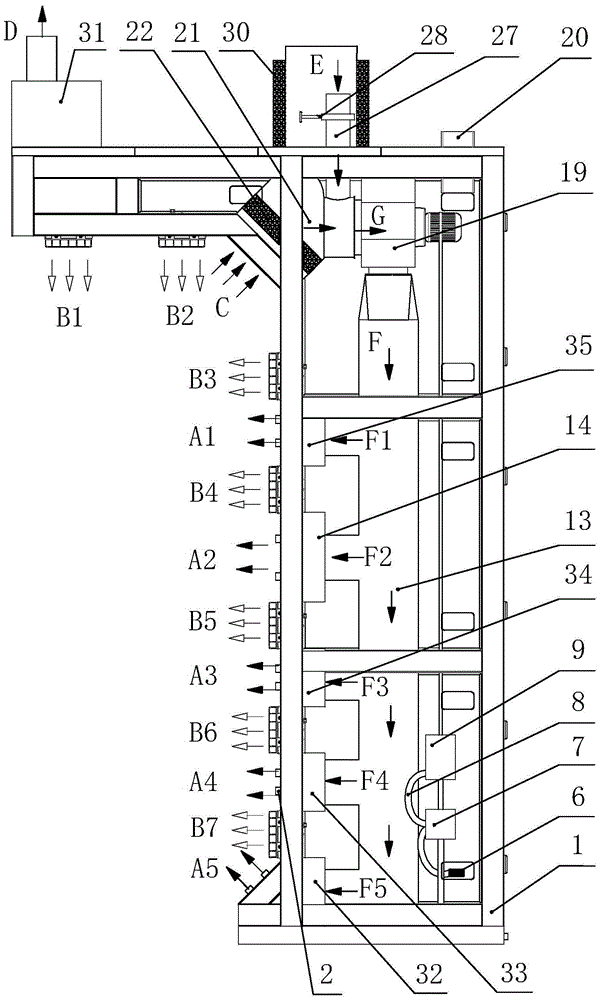

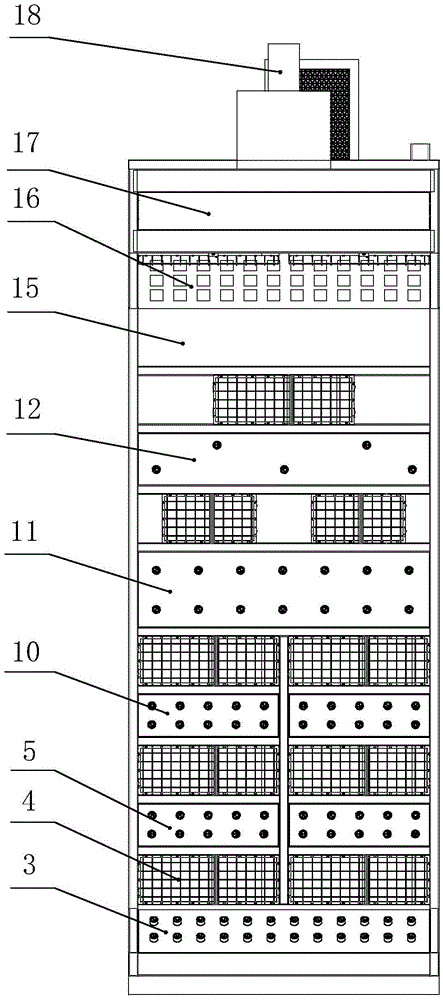

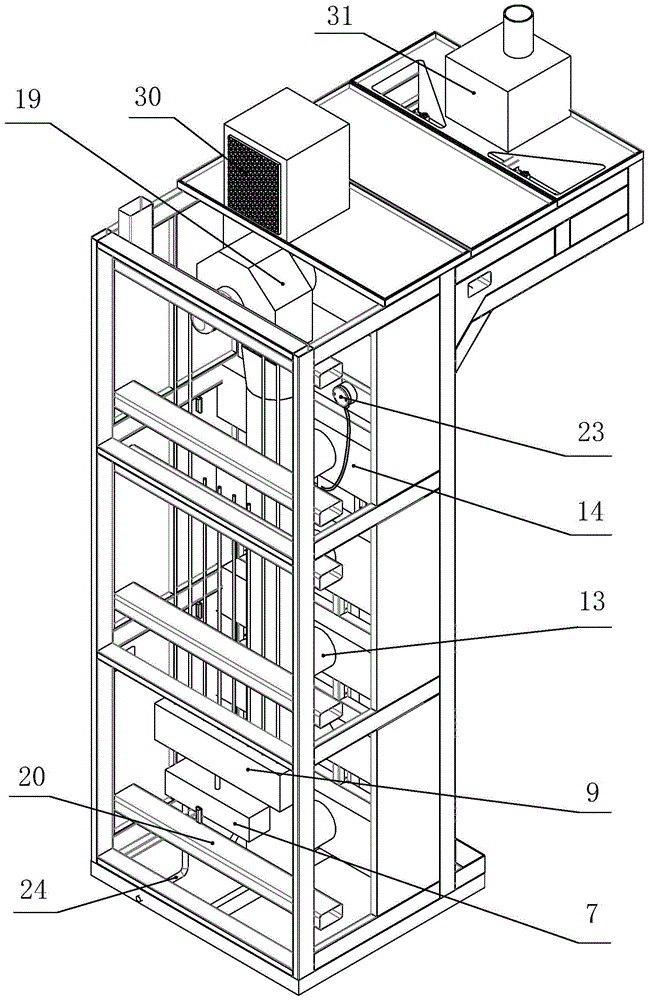

[0050]A passenger car gas catalytic flameless infrared radiation hot air internal circulation drying unit module, including a fixed bracket 1, the fixed bracket 1 has a C-shaped structure, a panel 25 is installed on the fixed bracket 1, and a hot air internal circulation is arranged inside the fixed bracket 1 system and a plurality of gas catalytic flameless infrared radiation heaters 4, the plurality of gas catalytic flameless infrared radiation heaters 4 are arranged in parallel in five rows, and each gas catalytic flameless infrared radiation heater 4 passes through gas supply pipes, secondary The gas supply adjustment transmitter 9, the primary gas supply adjustment transmitter 7, the gas intake pipe 24 are connected with the gas source,

[0051] The hot air internal circulation system includes an air supply system and a return air system connected to each other, and the air supply system includes a circulation fan 19, a main air supply pipe 13, a distribution air pipe, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com