Punching auxiliary device for steel skeleton polyethylene plastic composite pipe

A polyethylene plastic and auxiliary device technology, applied in metal processing and other directions, can solve the problems of low construction efficiency and large loss of production shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

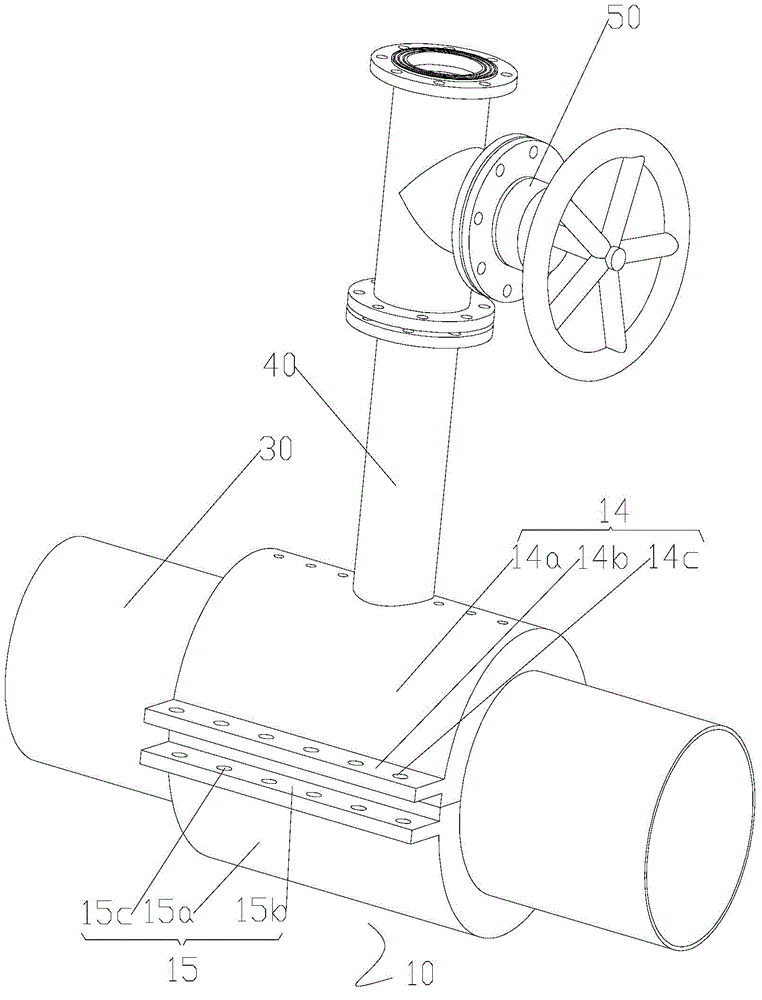

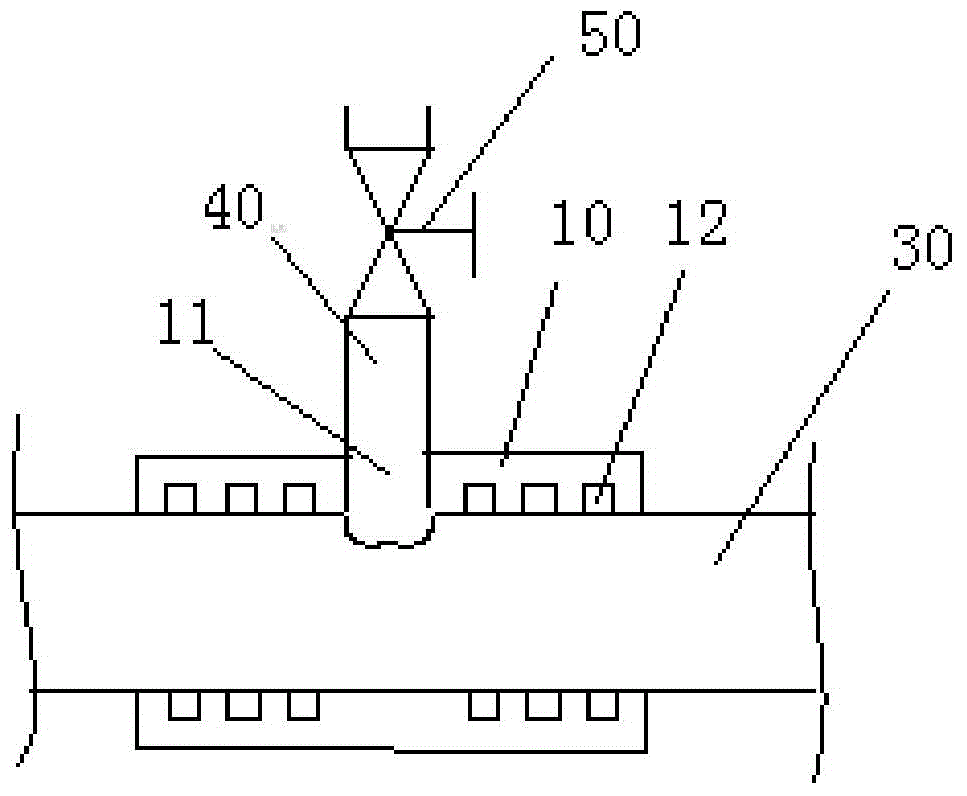

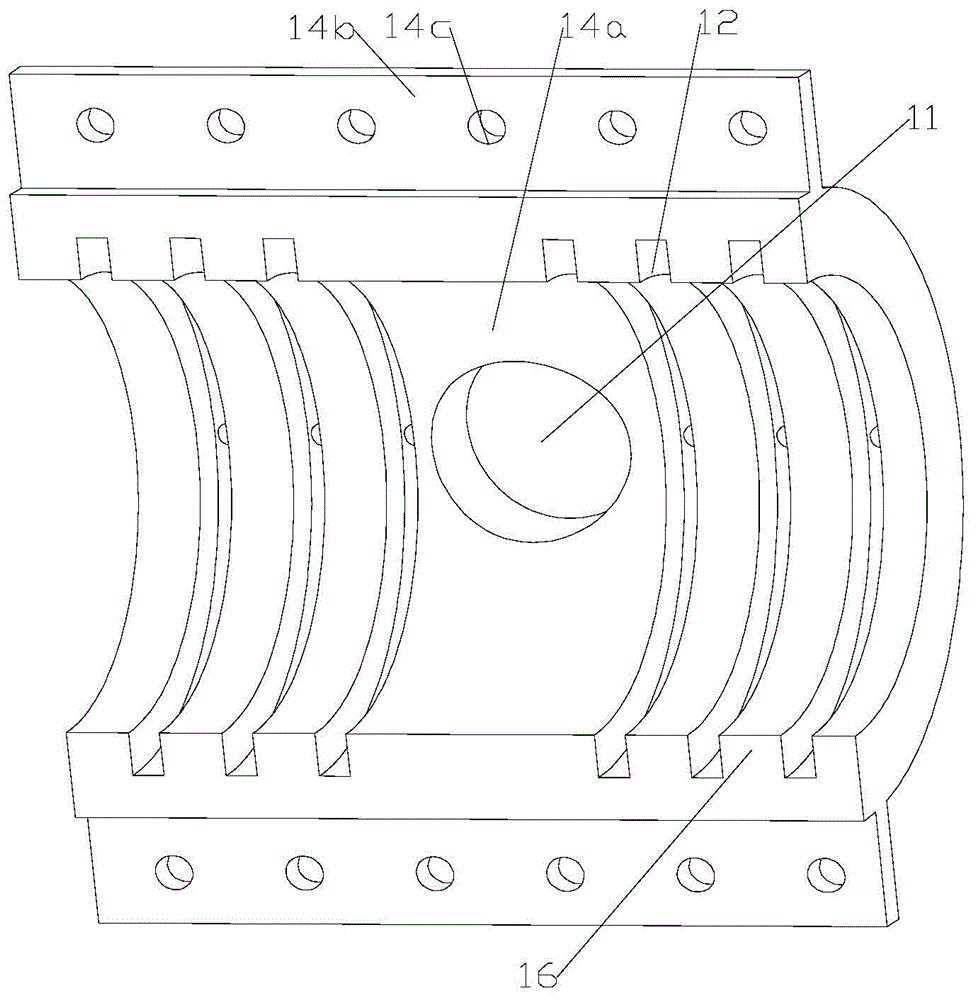

[0072] Taking softened sewage for heavy oil boilers with a conveying medium of 60°C as an example, steel skeleton polyethylene plastic composite pipe 30 with a rated pressure of 1.6MPa and a nominal diameter of DN400mm is connected to a DN150mm branch line with a pressurized hole. The hole pipe segment is a common pipe segment.

[0073] The length of the sealing sleeve 10 is 800mm, the thickness of the fixture is 50mm, and the diameter of the intended opening is 150mm. The diameter of the opening 11 is 155 mm, and the inner diameter of the connecting pipe section 40 is 155 mm. The width of the protruding structure 16 is 50 mm, the groove width of the sealing groove 12 is 25 mm, the groove depth is 25 mm, and the inner diameter of the arc surface of the protruding structure 16 is 432 mm and 435 mm. The thickness of the positioning gasket 20 is 10mm; the thickness of the positioning gasket 20 is 6mm, and three positioning pin holes are opened equidistantly on it, the nail lengt...

Embodiment 2

[0075] Taking softened sewage for heavy oil boilers with a conveying medium of 60°C as an example, steel skeleton polyethylene plastic composite pipe 30 with a rated pressure of 1.6MPa and a nominal diameter of DN400mm is connected to a DN150mm branch line with a pressurized hole. The hole pipe segment is the pipeline joint.

[0076] The diameter of the pipeline joint is 480mm, the diameter of the pipeline is 432mm, the thickness of the joint is 24mm, and the length of the pipeline joint is 335mm. The length of the sealing sleeve 10 is 635 mm, the thickness of the fixture is 50 mm, the diameter of the planned opening is 150 mm, the diameter of the opening 11 is 155 mm, and the inner diameter of the connecting pipe section 40 is 155 mm. The width of the protruding structure 16 is 50 mm, the groove width of the sealing groove 12 is 25 mm, and the groove depth is 25 mm. The inner diameter of the arc surface of the protruding structure 16 is 432 mm, and the distance between the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com