Automatic alarm device of load for CNC motion shaft and method thereof

An automatic alarm device and automatic alarm technology are applied in the direction of measuring devices, force sensors related to bearings, force/torque/power measuring instruments, etc., which can solve problems such as delaying production progress, equipment monitoring, and manual supervision that cannot be completely replaced. Achieve the effects of optimizing production planning and management, facilitating construction, and enhancing value and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

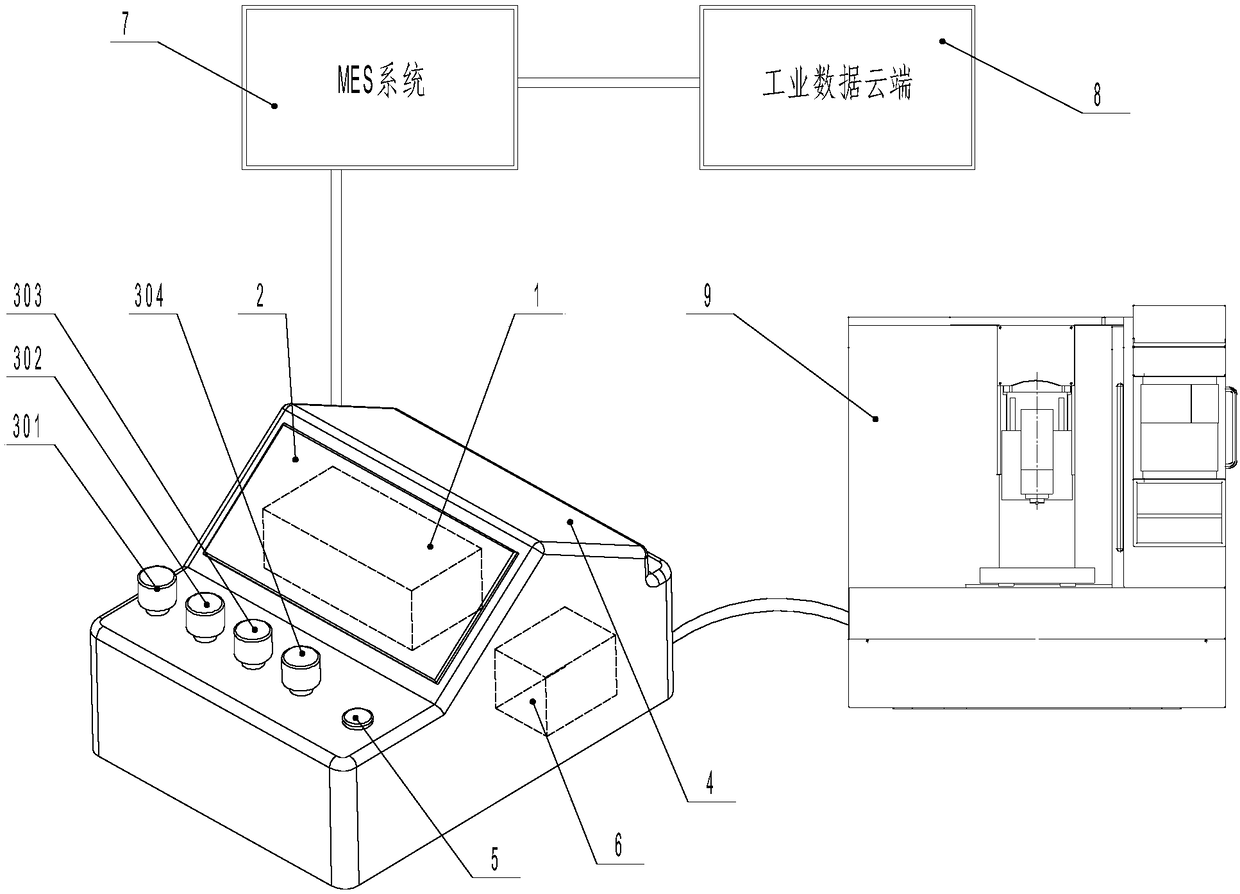

[0037] A CNC motion shaft load automatic alarm device, comprising a collector 1, a computer 2, an alarm 3, a casing 4, and a PLC programmable controller 6, wherein:

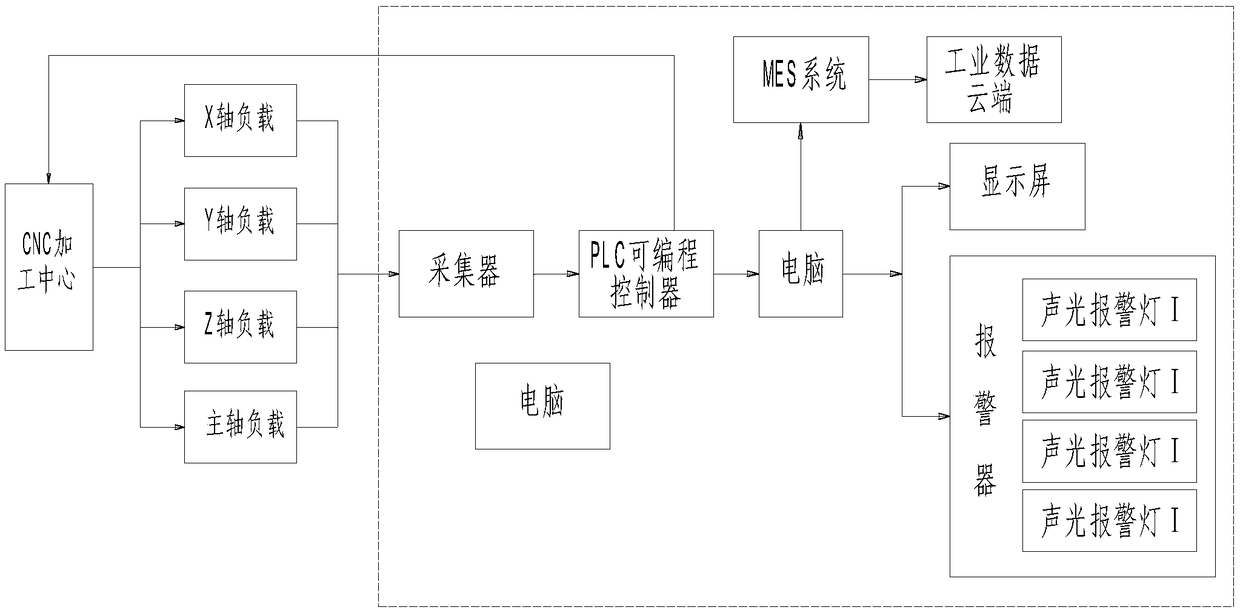

[0038] Described collector 1 adopts Dlink collector, and this collector 1 is installed in the shell 4, and the input end of collector 1 is connected with the X-axis, Y-axis, Z-axis and main shaft of CNC machining center 9, is used for realizing to each For the collection and transmission of the load data of the motion shaft, the output end of the collector 1 is connected to the input end of the PLC programmable controller 6;

[0039] The PLC programmable controller 6 is installed in the casing 4, and the output terminal of the PLC programmable controller 6 is connected with the computer 2 for calculating the load data of each moving axis.

[0040] The computer 2 adopts an industrial tablet computer, and the computer 2 is installed on the shell 4, and the output terminals of the computer 2 are respectively connect...

Embodiment 2

[0044] An automatic alarm method for CNC motion axis load, the method is to collect the load data of the X axis, Y axis, Z axis and the main shaft of the CNC machining center 9 respectively through the collector 1, and then transmit the load data of each motion axis to the PLC After calculation by the programmable controller, it is transmitted to computer 2. Computer 2 compares the load data of each motion axis with the set load. If the actual processed load data of each motion axis is greater than the set load data, it will be sent in time. Command to the CNC machining center to stop the machining operation of the CNC machining center, waiting for the intervention of the operator and equipment operation and maintenance personnel; at the same time output the alarm signal to the alarm corresponding to the motion axis, and store and output the corresponding overload data information ; When the alarm device receives the alarm signal, it sends out an audible and visual alarm to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com