Film blowing machine with air supplementing device as well as method for supplementing air for film bubbles

A film blowing machine and film bubble technology, which is applied in the field of plastic film manufacturing equipment, can solve problems such as laborious operation, heat loss of raw materials, and increased energy consumption costs, so as to achieve simple and labor-saving operations, reduce energy consumption costs, and ensure production progress and product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

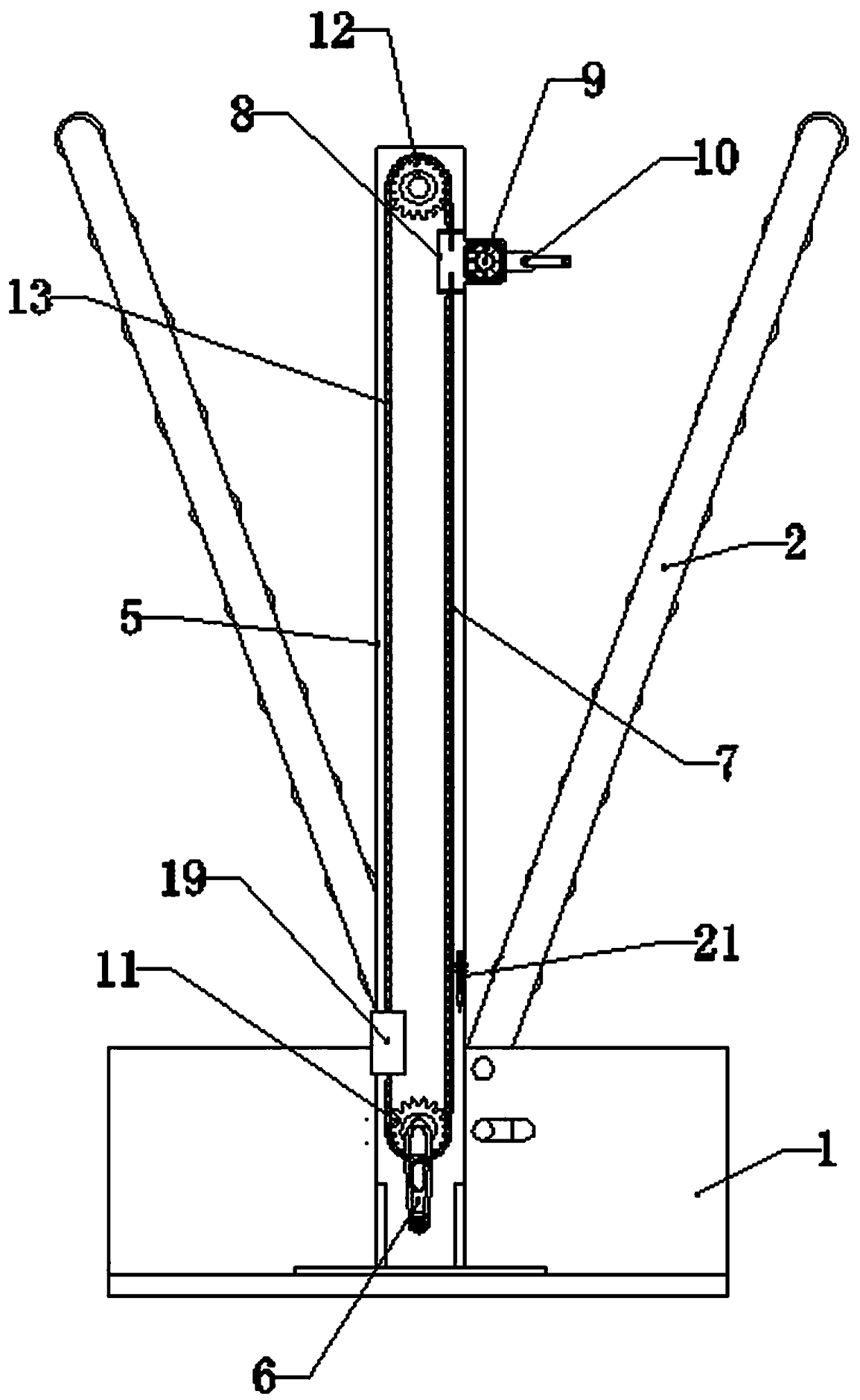

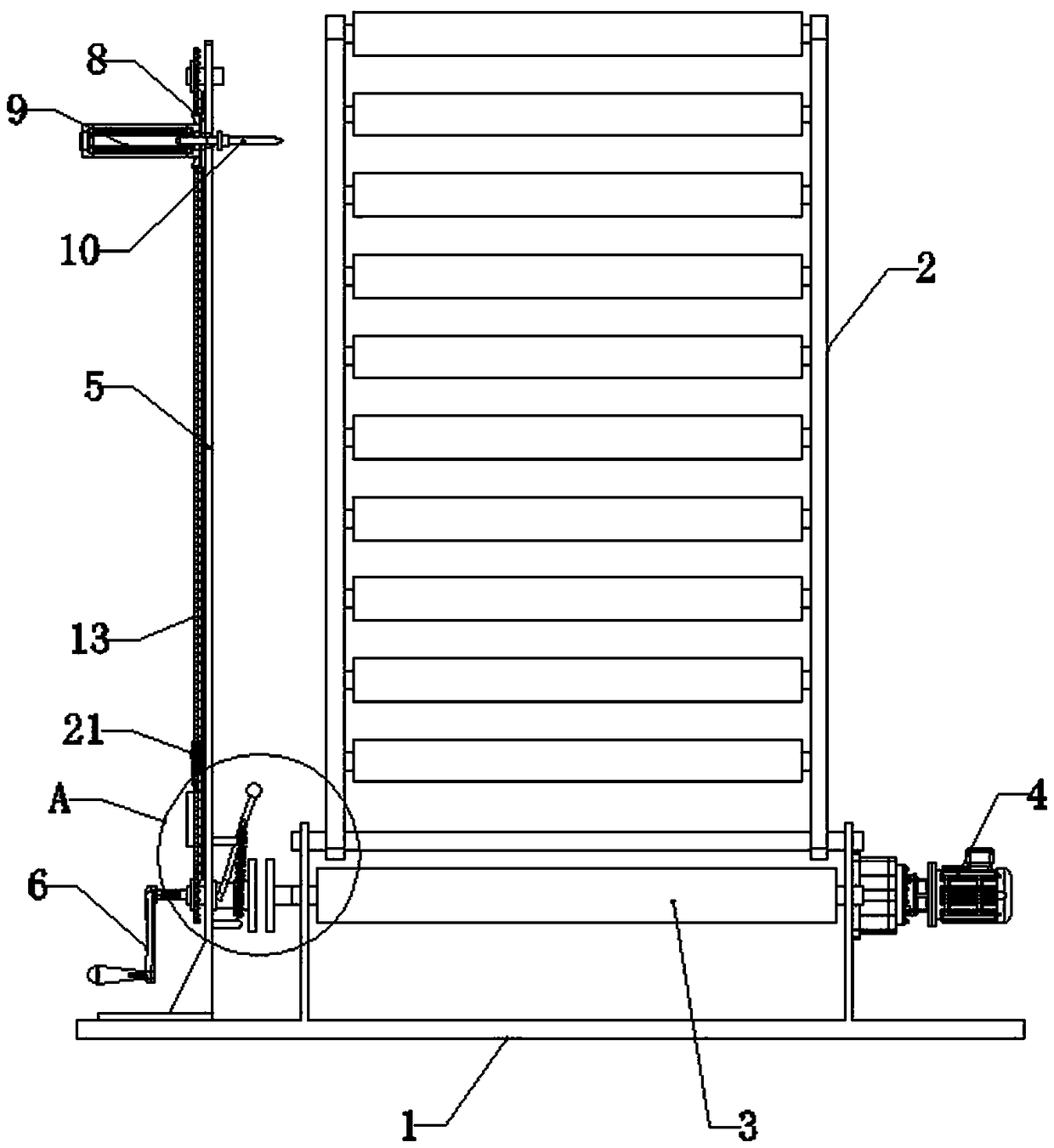

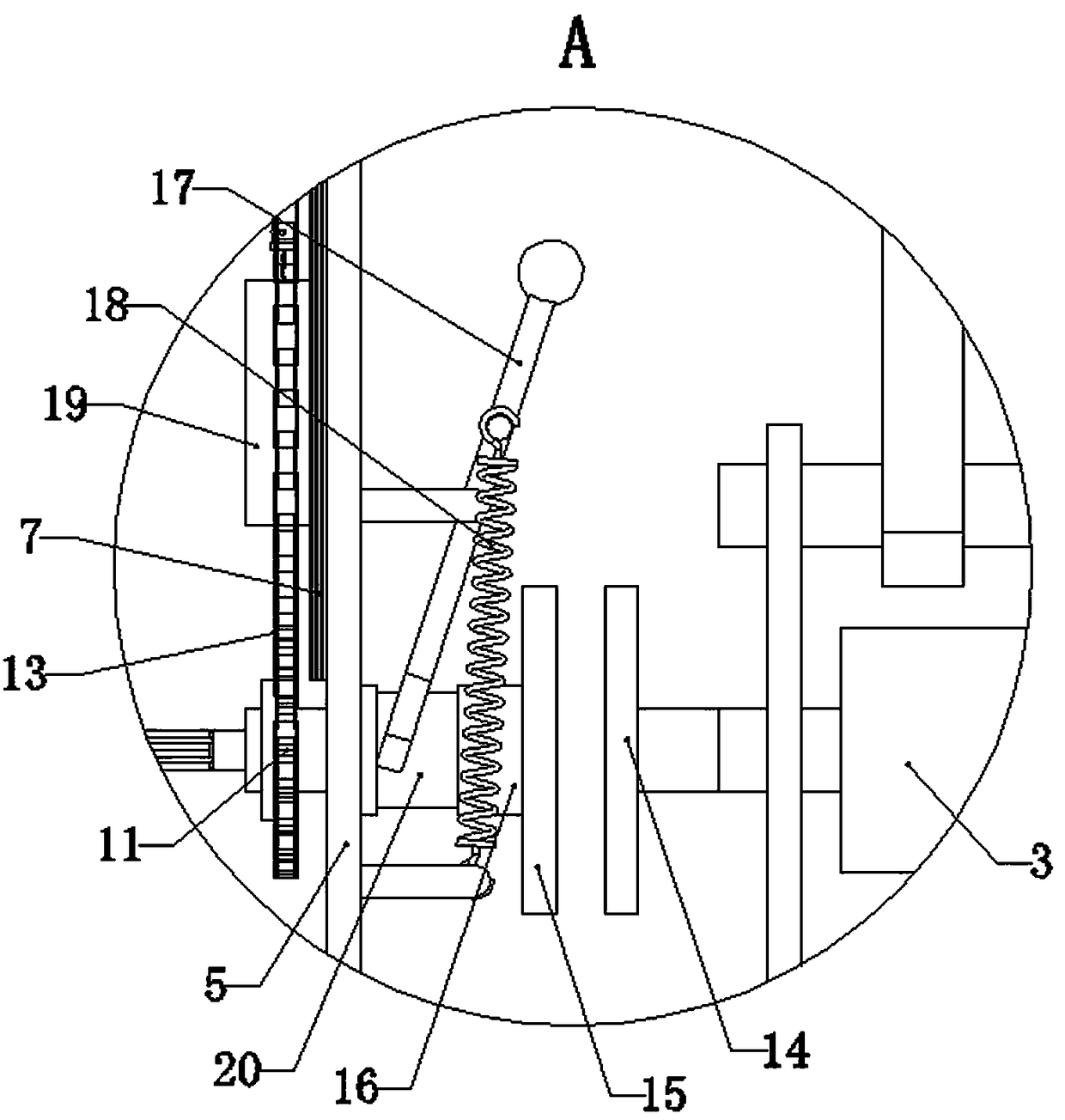

[0022] Such as Figure 1~Figure 7 As shown, a film blowing machine equipped with an air supply device includes a frame 1, a herringbone frame 2, a traction roller 3, a traction roller drive motor 4 and an air supply device.

[0023] The gas supply device is located at the side of the herringbone frame 2, and the gas supply device includes a support 5, a chain transmission mechanism, a hand crank 6, a guide rail 7, a slide block 8, a cylinder 9, a gas supply needle 10 and a clutch.

[0024] The bracket 5 is fixed on the frame 1, and the chain transmission mechanism and the guide rail 7 are installed on the bracket 5. The chain transmission mechanism includes a driving sprocket 11, a driven sprocket 12 and a chain 13, and the driving sprocket 11 is coaxial with the traction ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com