Online cleaning method for tubular reactors

A tubular reactor, phosphoric acid technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of inconvenient cleaning and maintenance, clogging of the mixing head of the tubular reactor, reduction of pipeline transportation space, etc., to improve the cleaning and maintenance efficiency. Maintenance efficiency, reducing pipe maintenance costs, inhibiting scaling and clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

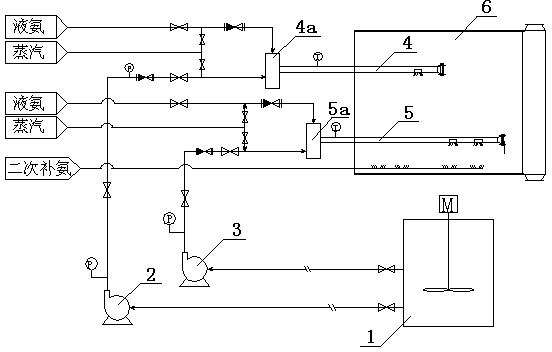

[0019] refer to figure 1 As shown, the 2×600,000 tons / year diammonium phosphate plant of Wengfu Phosphate Fertilizer Plant, two tubular reactors are installed in the drum granulator, and the phosphoric acid in tubular reactor A4 and tubular reactor B5 comes from The same acid distribution tank 1, the outlet of acid distribution tank 1, that is, the inlet of acid distribution pump A2 and acid distribution pump B3, is equipped with a filter at the inlet, which can effectively isolate the solids entering tubular reactor A4 and tubular reactor B For impurities, the filter implements a regular cleaning mechanism to ensure that the acid channel is unimpeded;

[0020] The outlets of acid pump A2 and acid pump B3 and the front ends of reaction mixing head A4a and mixing head B5a are equipped with pressure gauges to measure the internal pressure of the phosphoric acid delivery pipeline of tubular reactor A4 and tubular reactor B5 continuously, which can effectively Monitor and judge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com