Evaporating plating device and OLED panel evaporating plating method

An evaporation and panel technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem of affecting the service life of the metal mask, shadow effect, metal mask wrinkles, and abnormal evaporation patterns and other problems, to reduce the risk of fragmentation, improve life, and avoid abnormal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

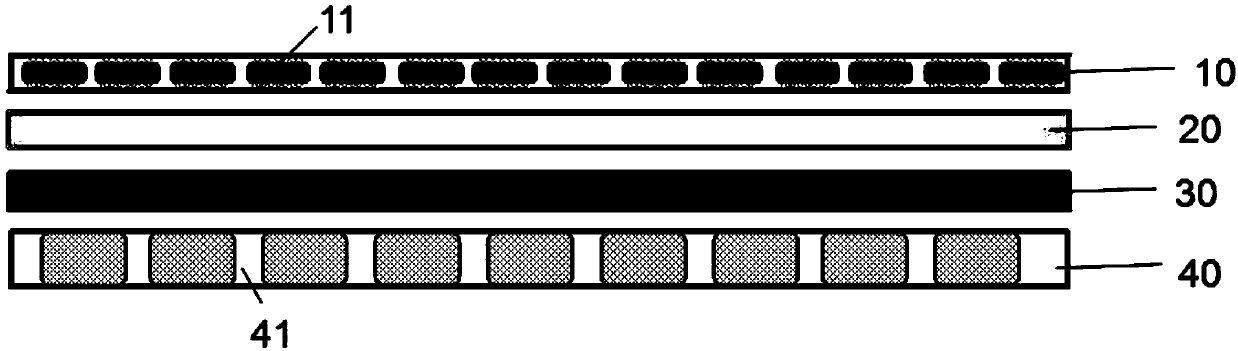

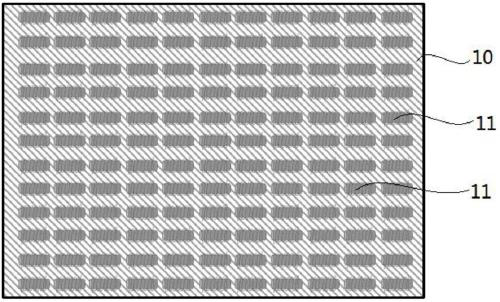

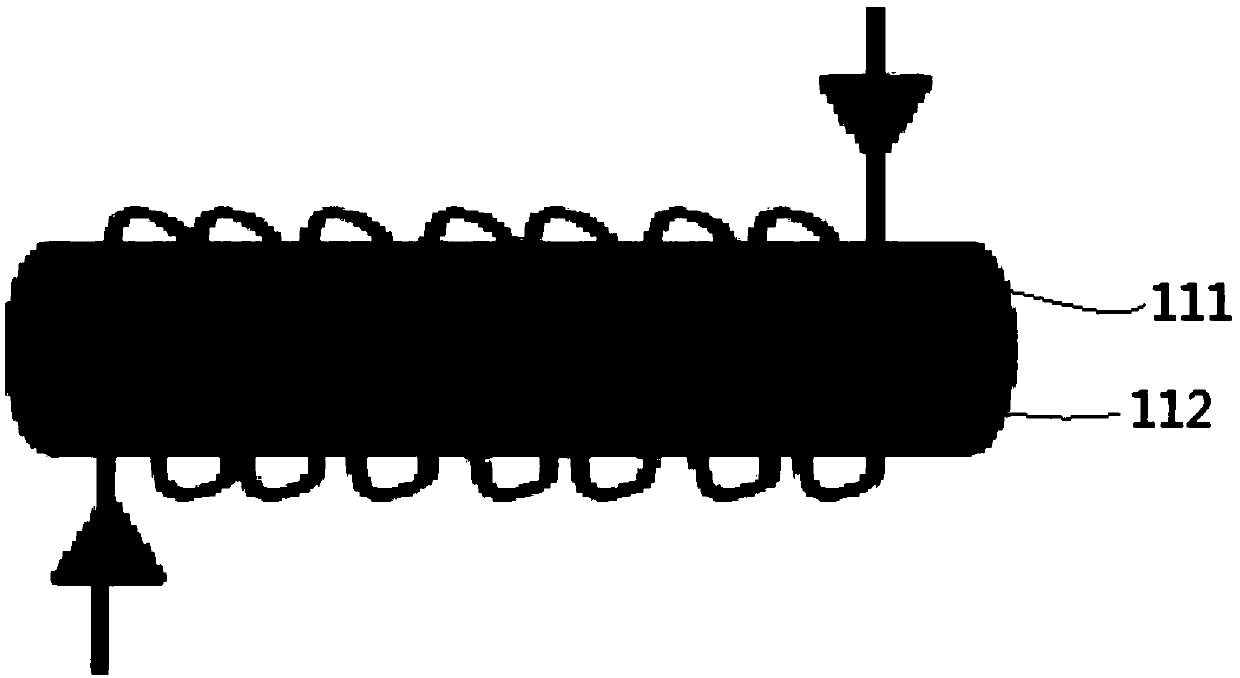

[0036] see Figure 1 to Figure 3 , this embodiment provides an evaporation device, which can be used for evaporation of different objects, especially for evaporation of sheet-like objects such as OLED panels.

[0037] The vapor deposition device is the same as the existing vapor deposition machine, and has a chamber for vapor deposition inside the vapor deposition machine, and a heating crucible and a holder for fixing the target substrate (that is, the object to be vapor deposited) are arranged in the chamber. magnetic board. Wherein, the heating crucible is used to hold the evaporation material and heat the evaporation material to make it evaporate; the magnetic plate is arranged above the heating crucible to fix the target substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com