Rubber airbag for manufacturing heat insulating layer of engine

A technology of rubber airbag and thermal insulation layer, applied in the coating and other directions, can solve the problems of the flow direction of the raw material of the thermal insulation layer, the poor conformity of the profile of the thermal insulation layer, the deviation of the profile of the thermal insulation layer, etc. The effect of mechanical properties and production schedule guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

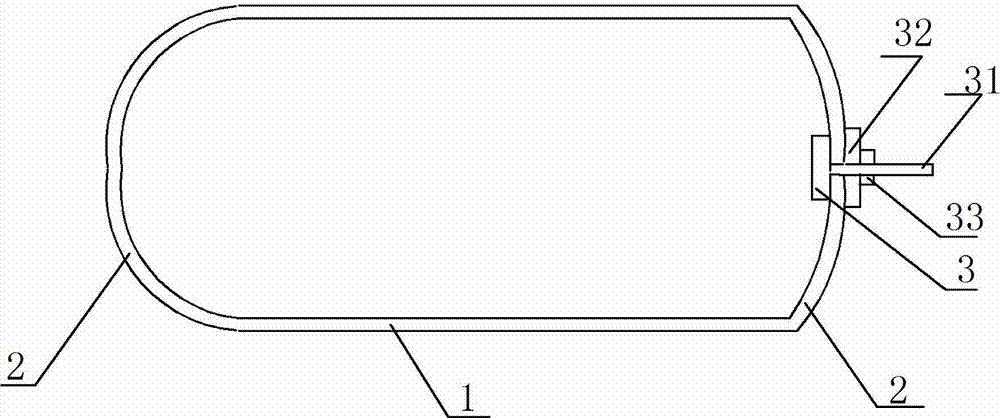

[0017] A rubber airbag used in the manufacture of engine insulation, such as figure 1 As shown, the capsule body 1 and the caps 2 at both ends are included, the thickness is 2mm, the capsule body 1 and the caps 2 are integrally formed, and one of the caps is provided with an inflator 3, and the inflator includes a T-shaped gas nozzle 31, T The T-shaped gas nozzle 31 is fixed on the head through the pressure plate 32 and the nut 33;

Embodiment 2

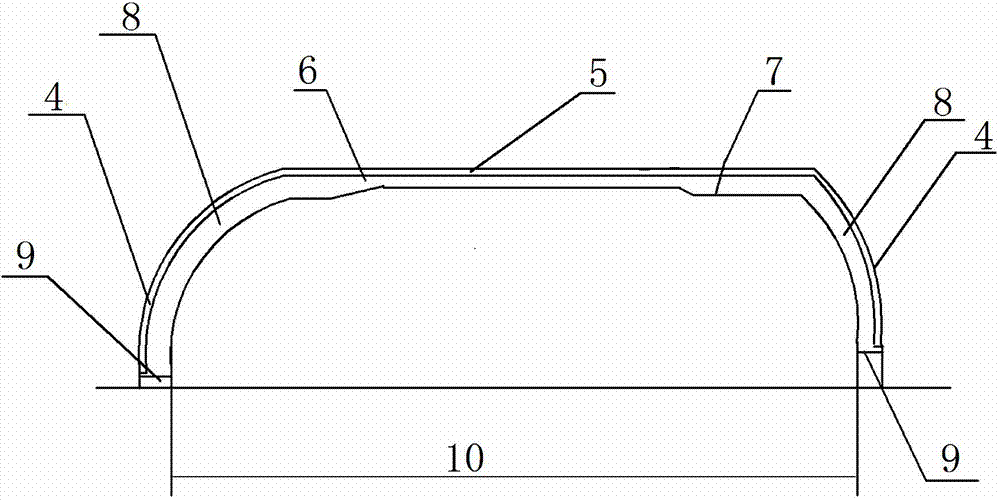

[0019] A rubber airbag used in the manufacture of engine insulation, such as figure 1 and figure 2 As shown, the capsule body 1 and the caps 2 at both ends are included, the thickness is 2mm, the capsule body 1 and the caps 2 are integrally formed, and one of the caps is provided with an inflator 3, and the inflator includes a T-shaped gas nozzle 31, T The T-shaped gas nozzle 31 is fixed on the head through the pressure plate 32 and the nut 33;

[0020] Wherein, the capsule is cylindrical, and its outer diameter is 99.5% of the minimum diameter of the cylinder section of the engine heat insulation layer to be formed.

[0021] The head is a part of an ellipsoid, the long radius of the ellipsoid is equal to the radius of the capsule body, and the short radius is the short radius of the head of the engine case to be processed minus the thickness of the heat insulation layer at the mouth of the head.

[0022] The total length of the airbag is 99.8% of the distance between the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com