Patents

Literature

44results about How to "Eliminate rework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

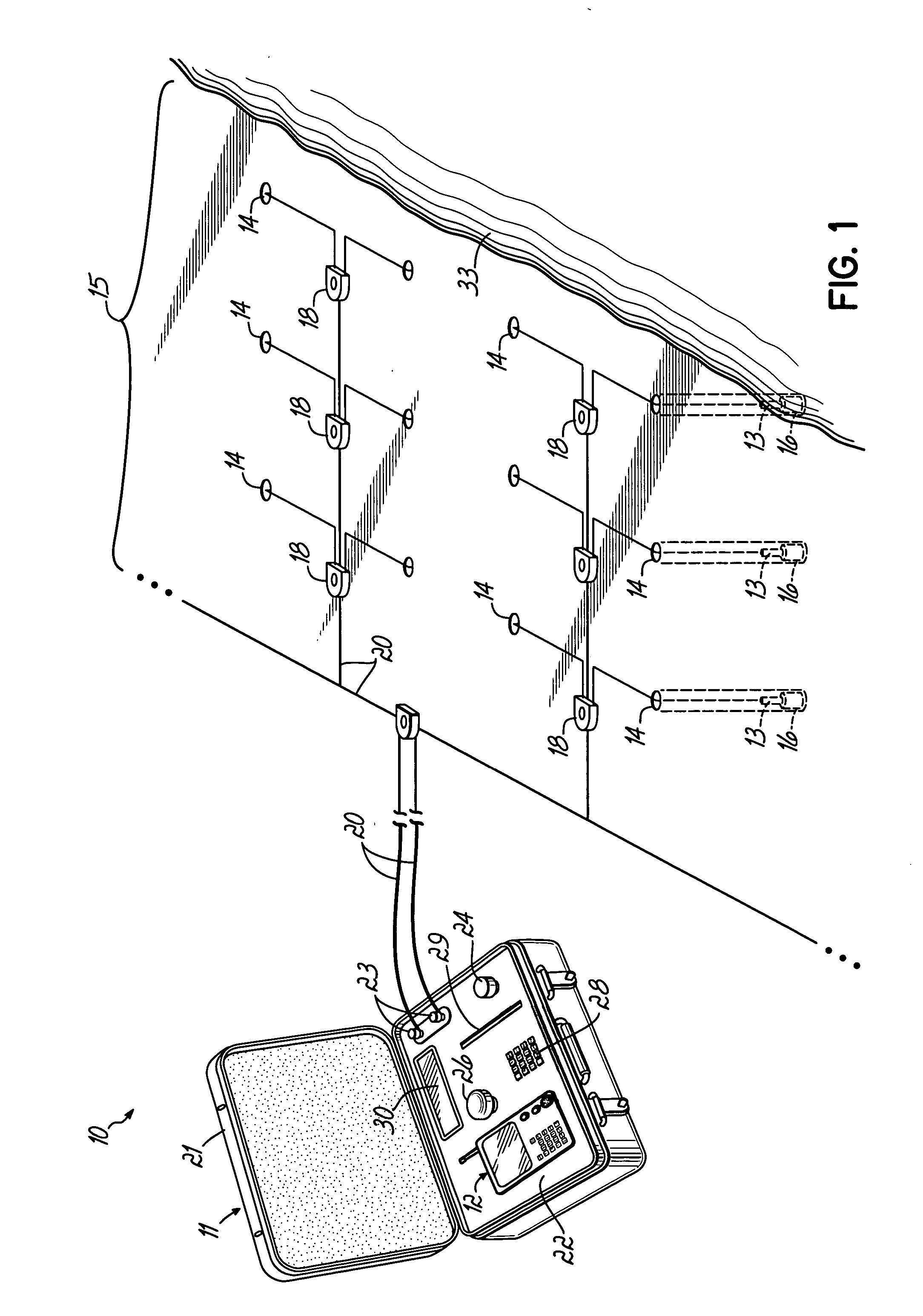

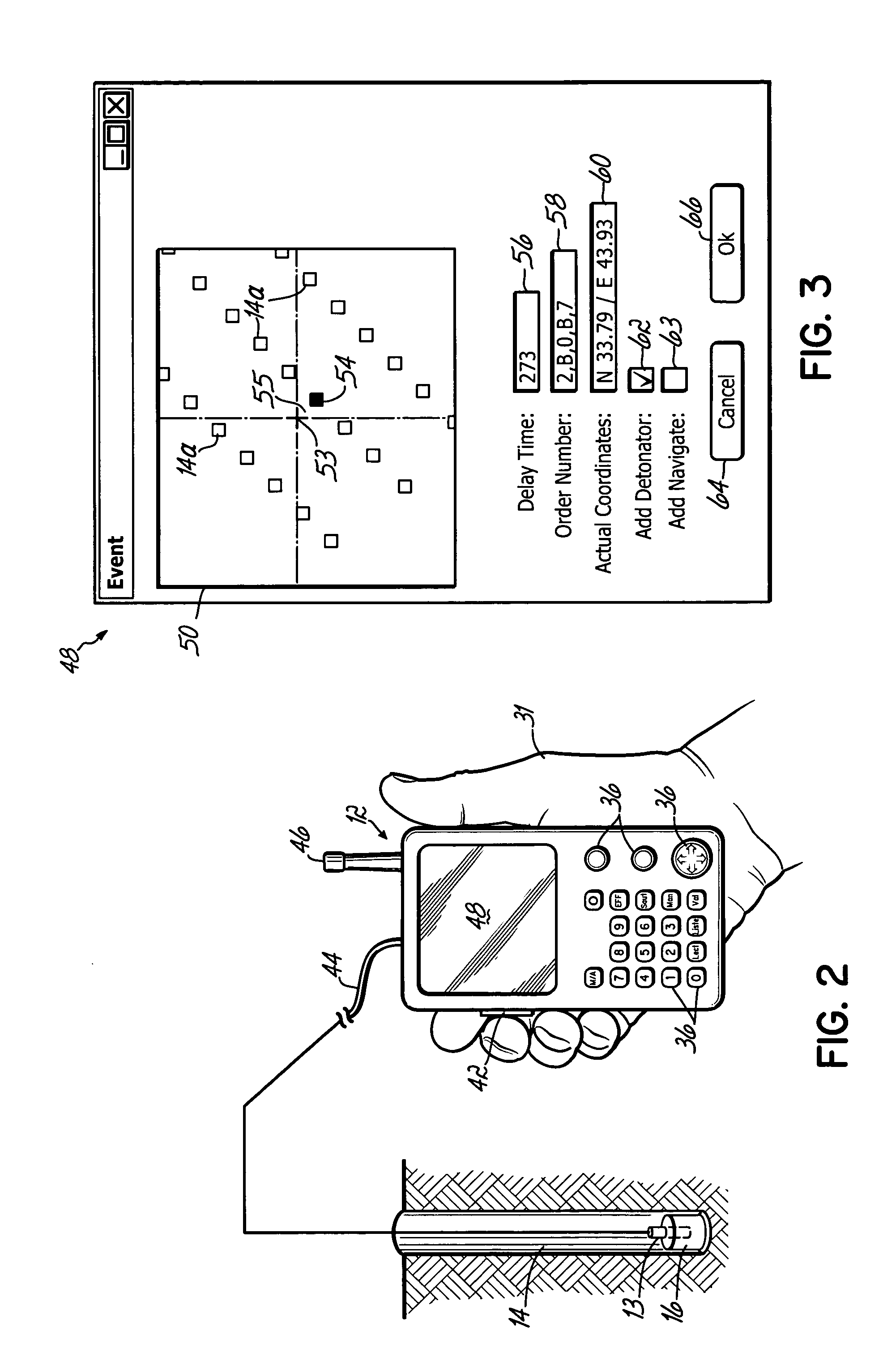

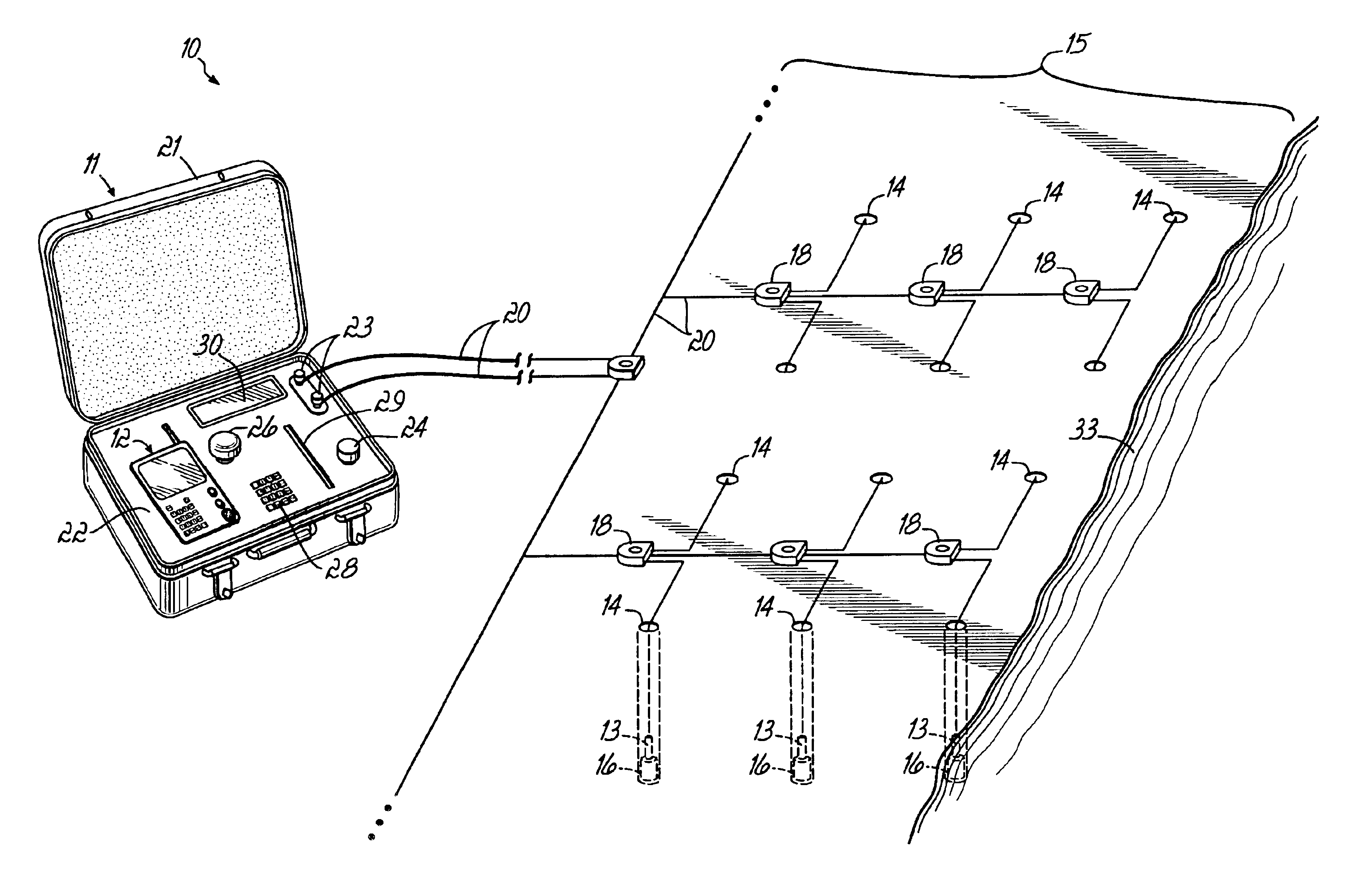

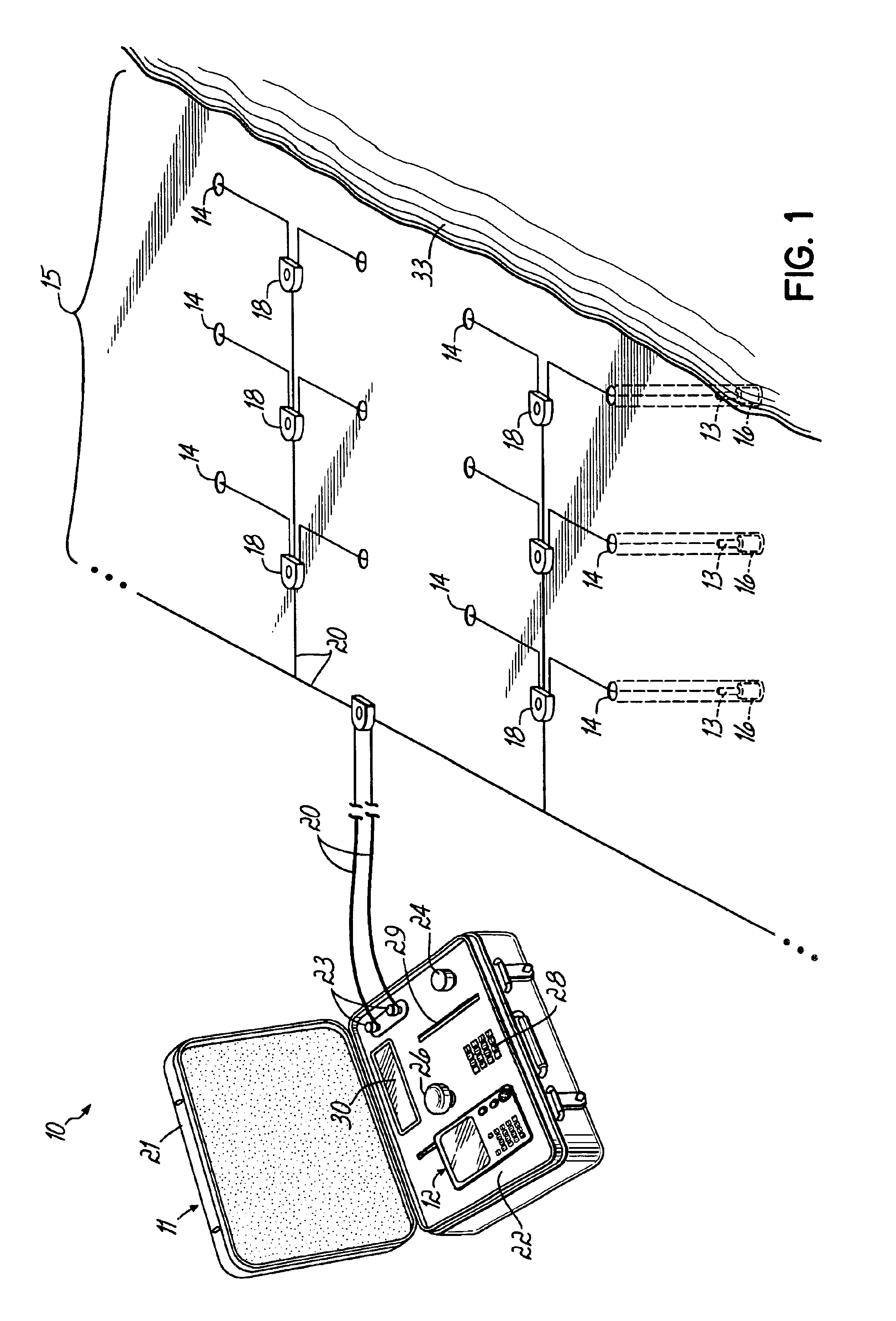

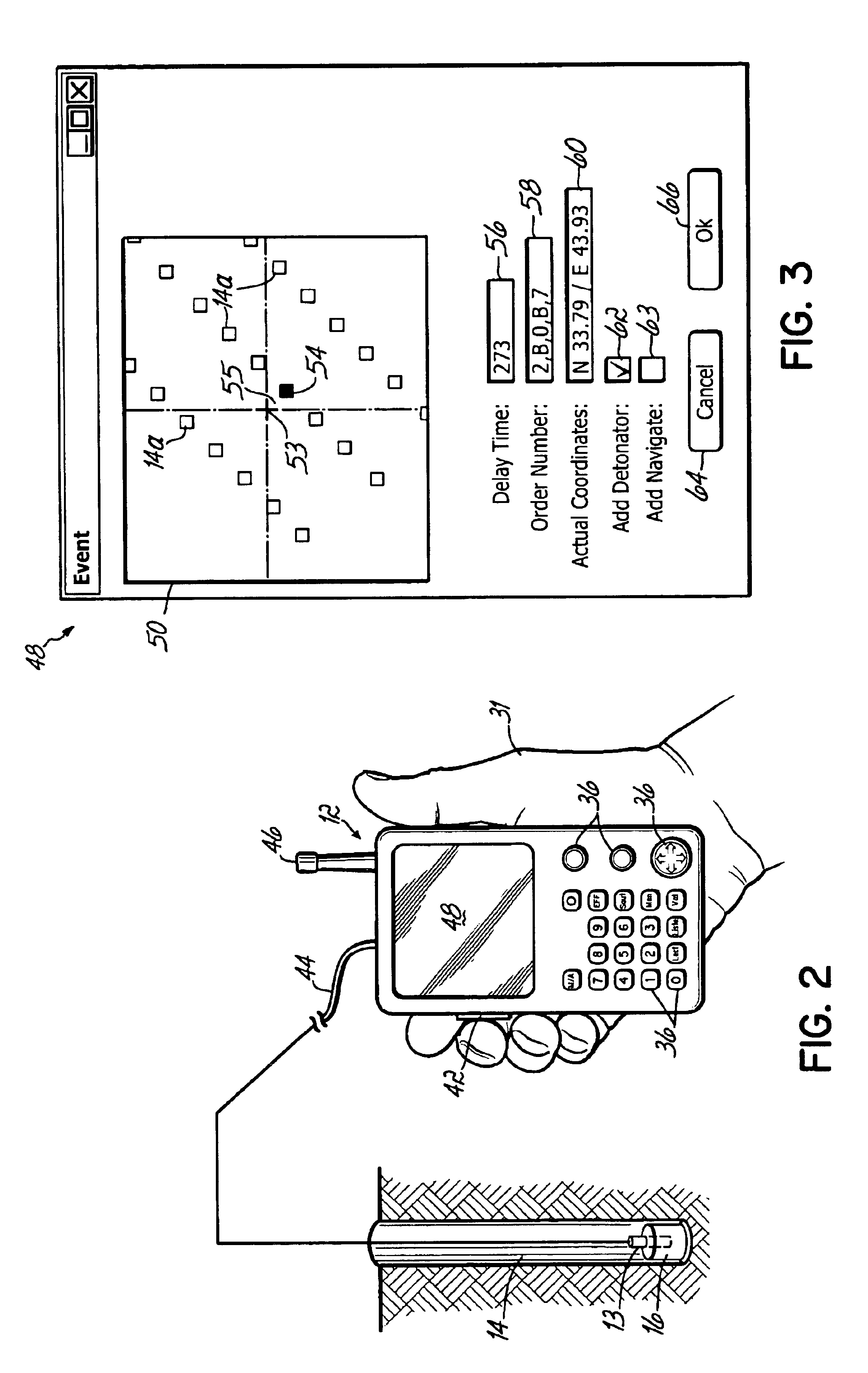

Positional blasting system

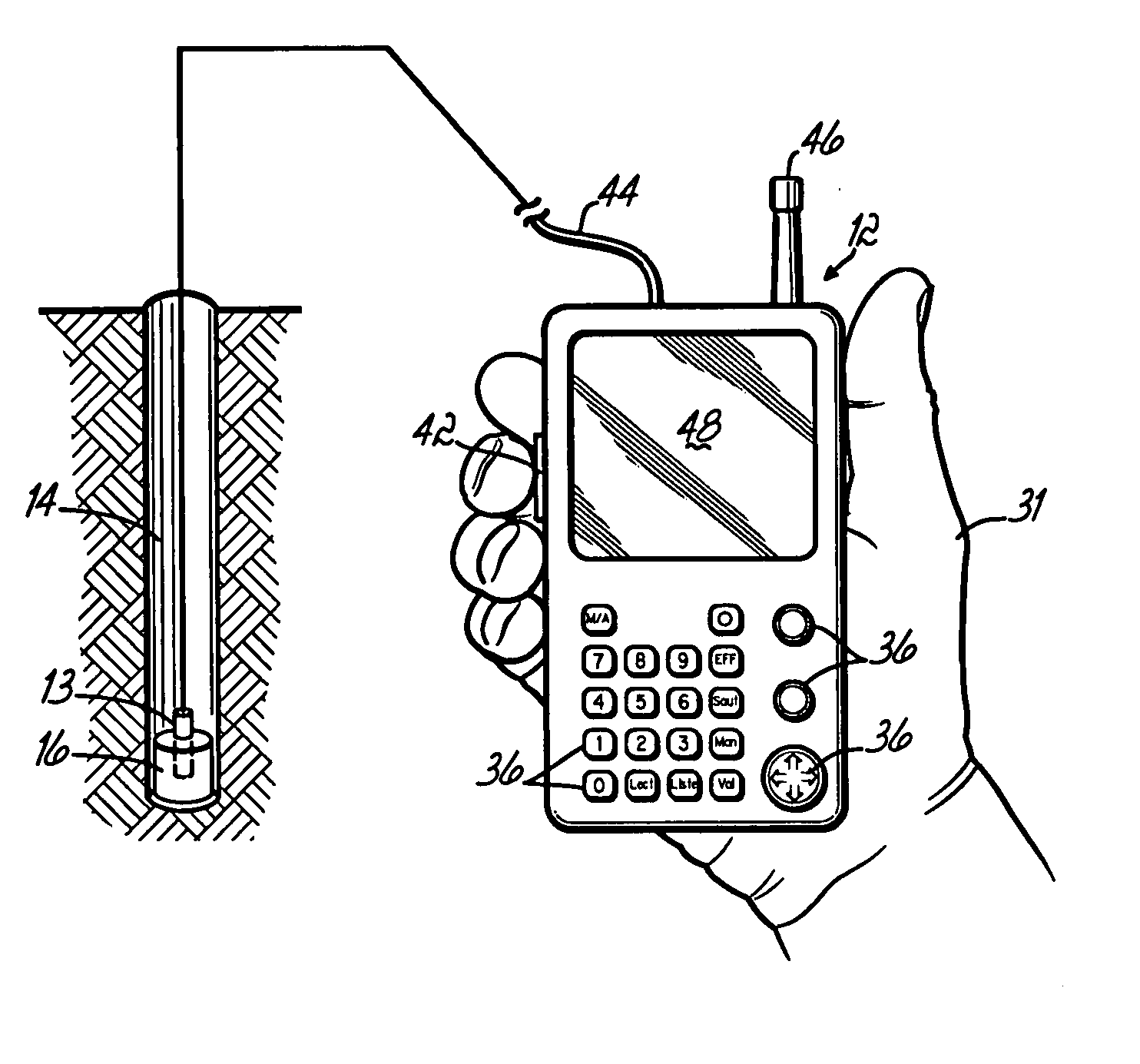

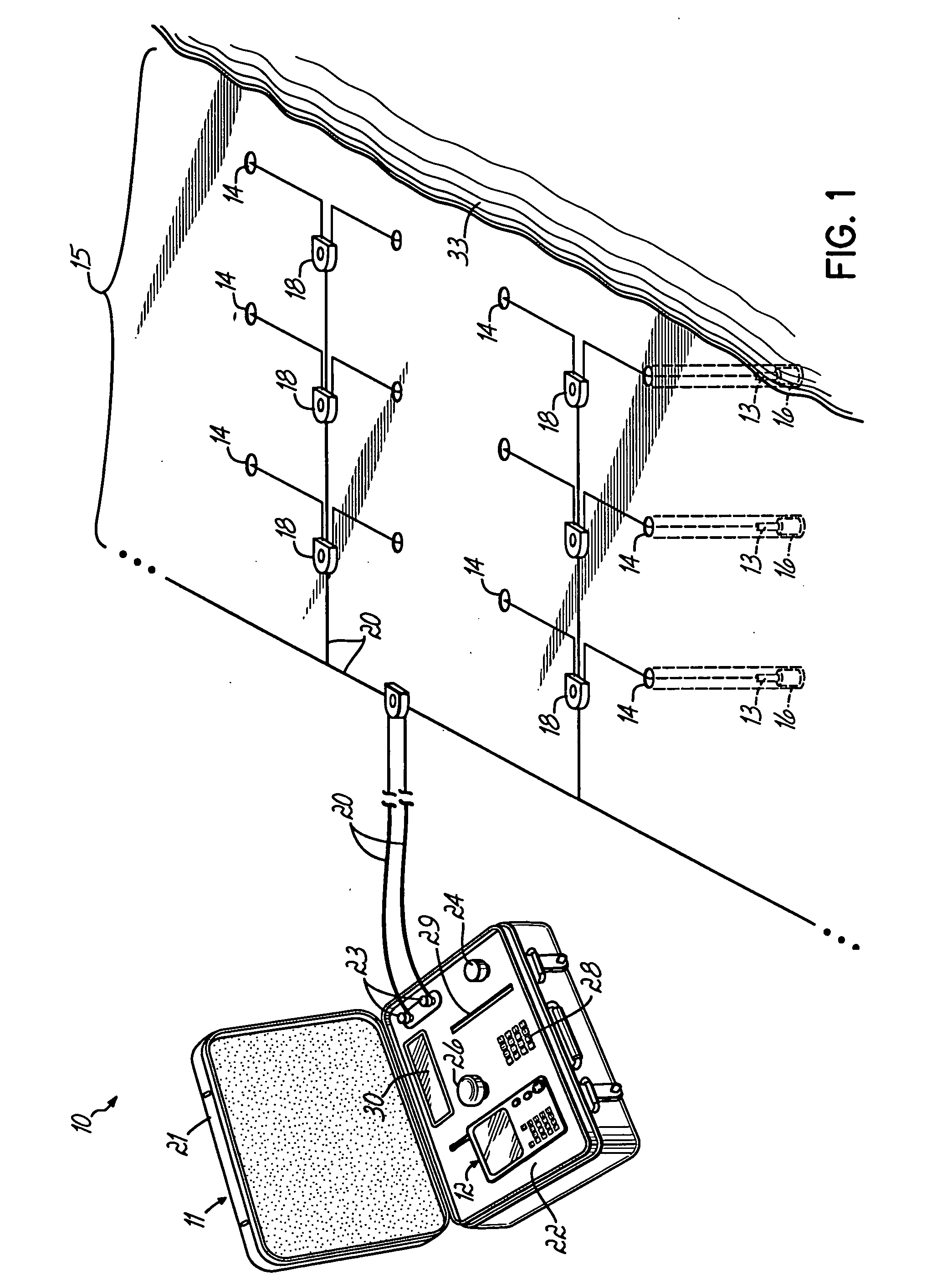

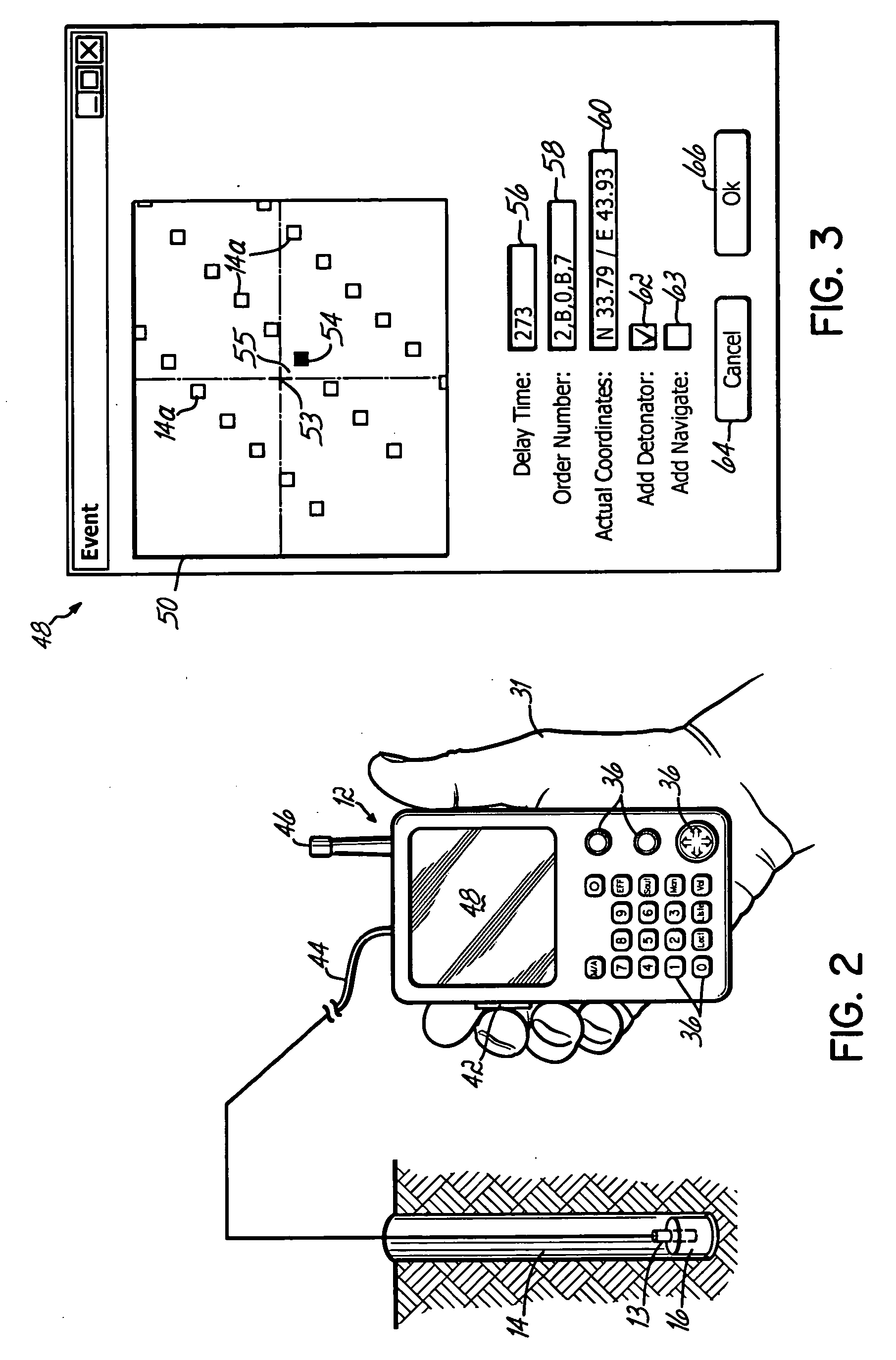

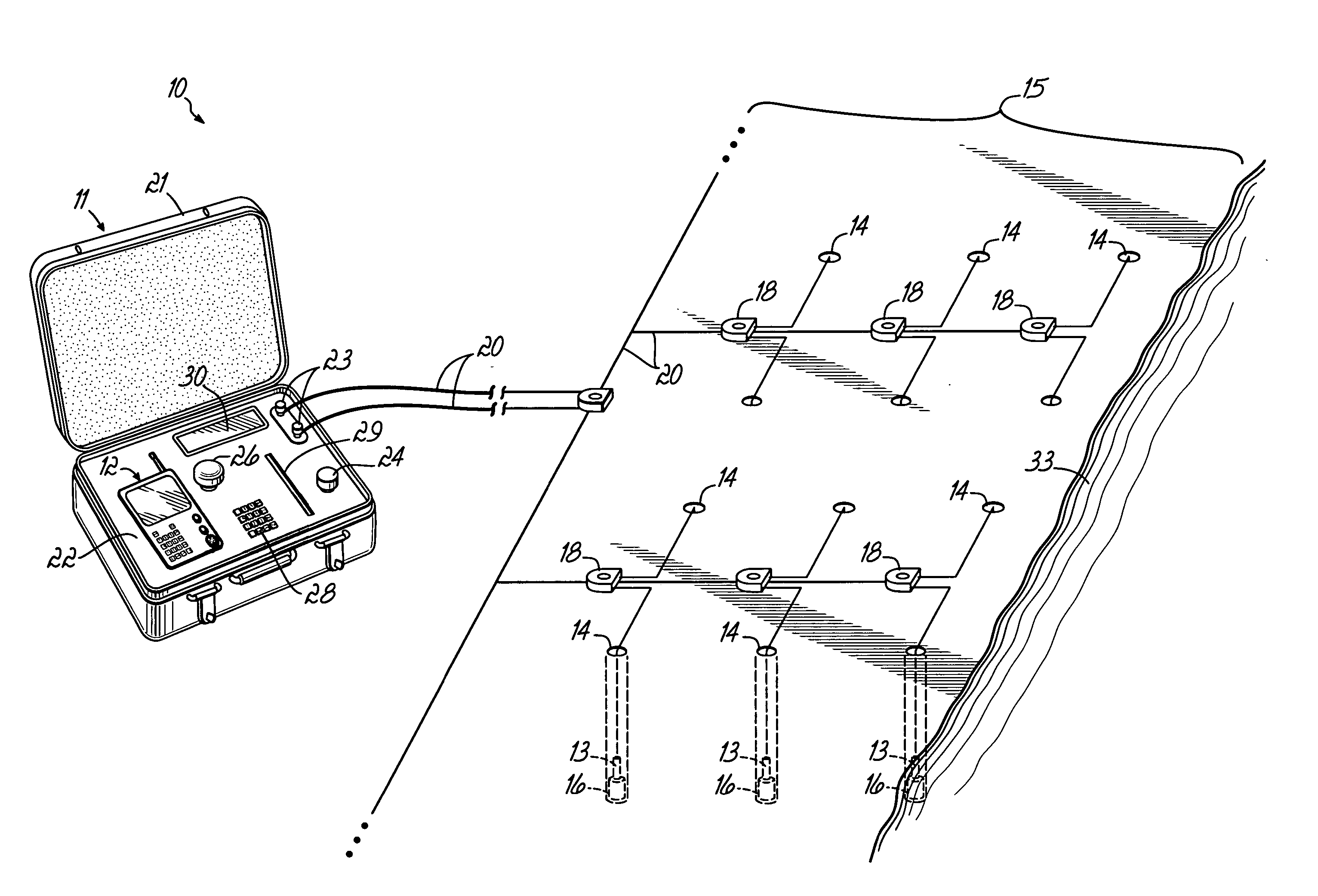

InactiveUS20050217525A1Easy to useAccurate locationBlasting cartridgesBlastingDetonatorLocation detection

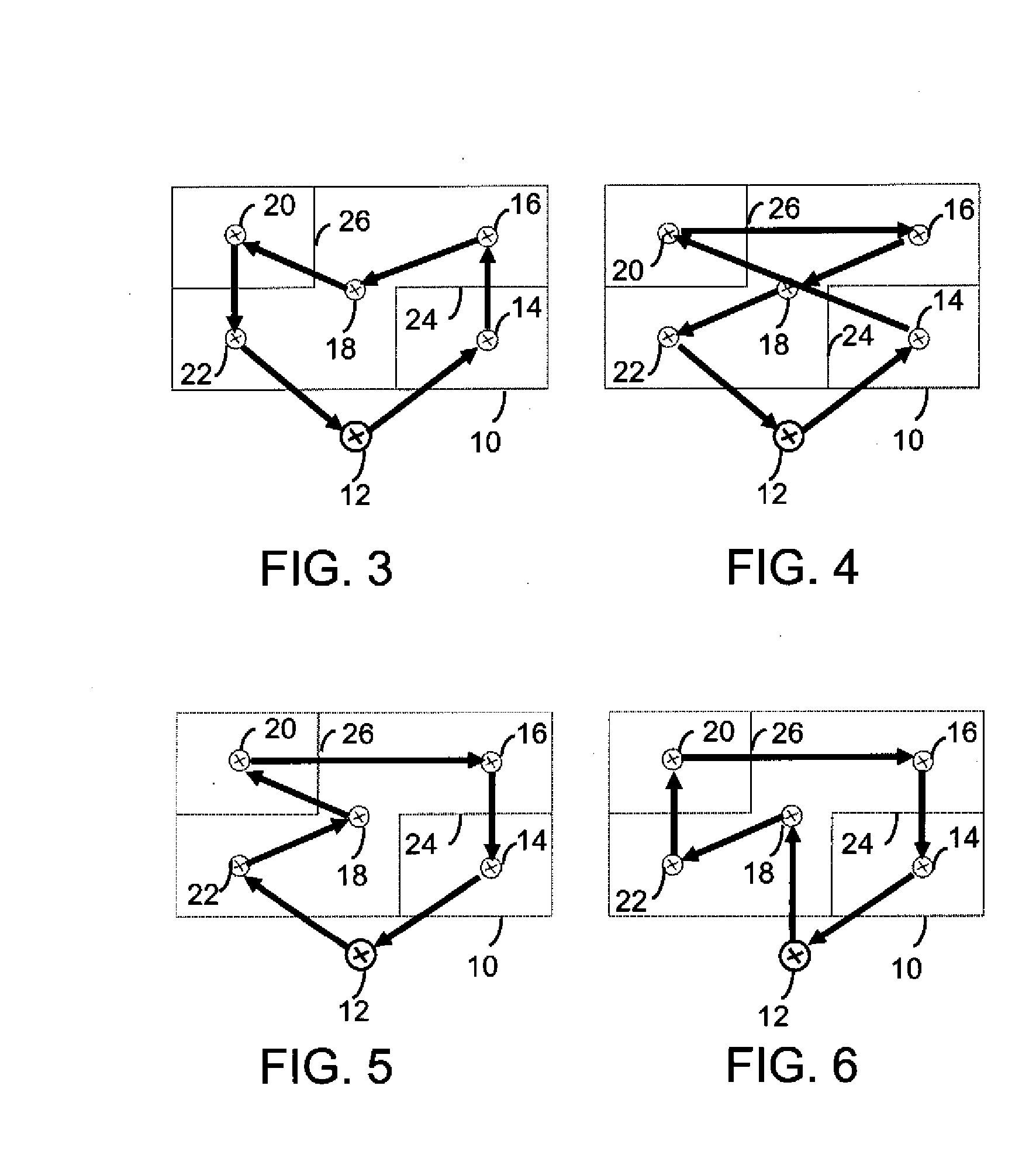

A blasting system facilitates the actuation of a plurality of programmable detonators according to a desired blasting pattern, to cause the discharge of a plurality of associated charges, by downloading to the detonators blasting information that can be automatically determined by a portable handheld unit that incorporates a positional detecting device, such as a GPS device. The blasting information for any given detonator can be determined by the handheld unit as a function of the distance and the direction of the movement of the unit to the detonator, and / or by the actual GPS location while at the site of the detonator. This automatic determination of blasting information, and particularly the delay times, based on the movement of the unit to the detonator, eliminates error prone human calculations of the delay times needed for multiple detonators at a blasting site. This simplifies the operations and procedures needed for achieving a desired blasting pattern, without sacrificing safety or quality.

Owner:DAVEY BICKFORD USA

Positional blasting system

A blasting system facilitates the actuation of a plurality of programmable detonators according to a desired blasting pattern, to cause the discharge of a plurality of associated charges, by downloading to the detonators blasting information that can be automatically determined by a portable handheld unit that incorporates a positional detecting device, such as a GPS device. The blasting information for any given detonator can be determined by the handheld unit as a function of the distance and the direction of the movement of the unit to the detonator, and / or by the actual GPS location while at the site of the detonator. This automatic determination of blasting information, and particularly the delay times, based on the movement of the unit to the detonator, eliminates error prone human calculations of the delay times needed for multiple detonators at a blasting site. This simplifies the operations and procedures needed for achieving a desired blasting pattern, without sacrificing safety or quality.

Owner:DAVEY BICKFORD USA

Positional blasting system

A blasting system facilitates the actuation of a plurality of programmable detonators according to a desired blasting pattern, to cause the discharge of a plurality of associated charges, by downloading to the detonators blasting information that can be automatically determined by a portable handheld unit that incorporates a positional detecting device, such as a GPS device. The blasting information for any given detonator can be determined by the handheld unit as a function of the distance and the direction of the movement of the unit to the detonator, and / or by the actual GPS location while at the site of the detonator. This automatic determination of blasting information, and particularly the delay times, based on the movement of the unit to the detonator, eliminates error prone human calculations of the delay times needed for multiple detonators at a blasting site. This simplifies the operations and procedures needed for achieving a desired blasting pattern, without sacrificing safety or quality.

Owner:DAVEY BICKFORD USA

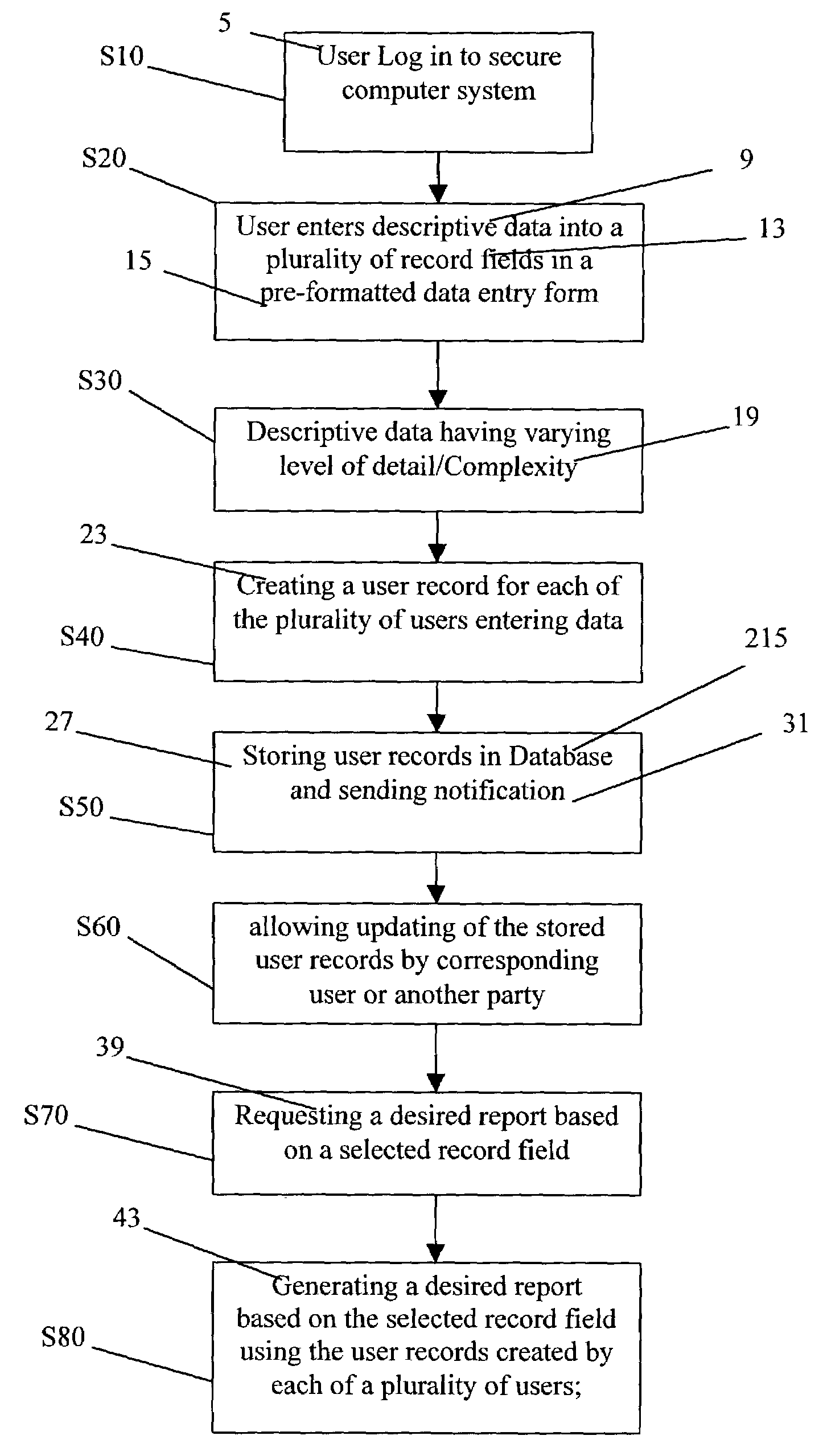

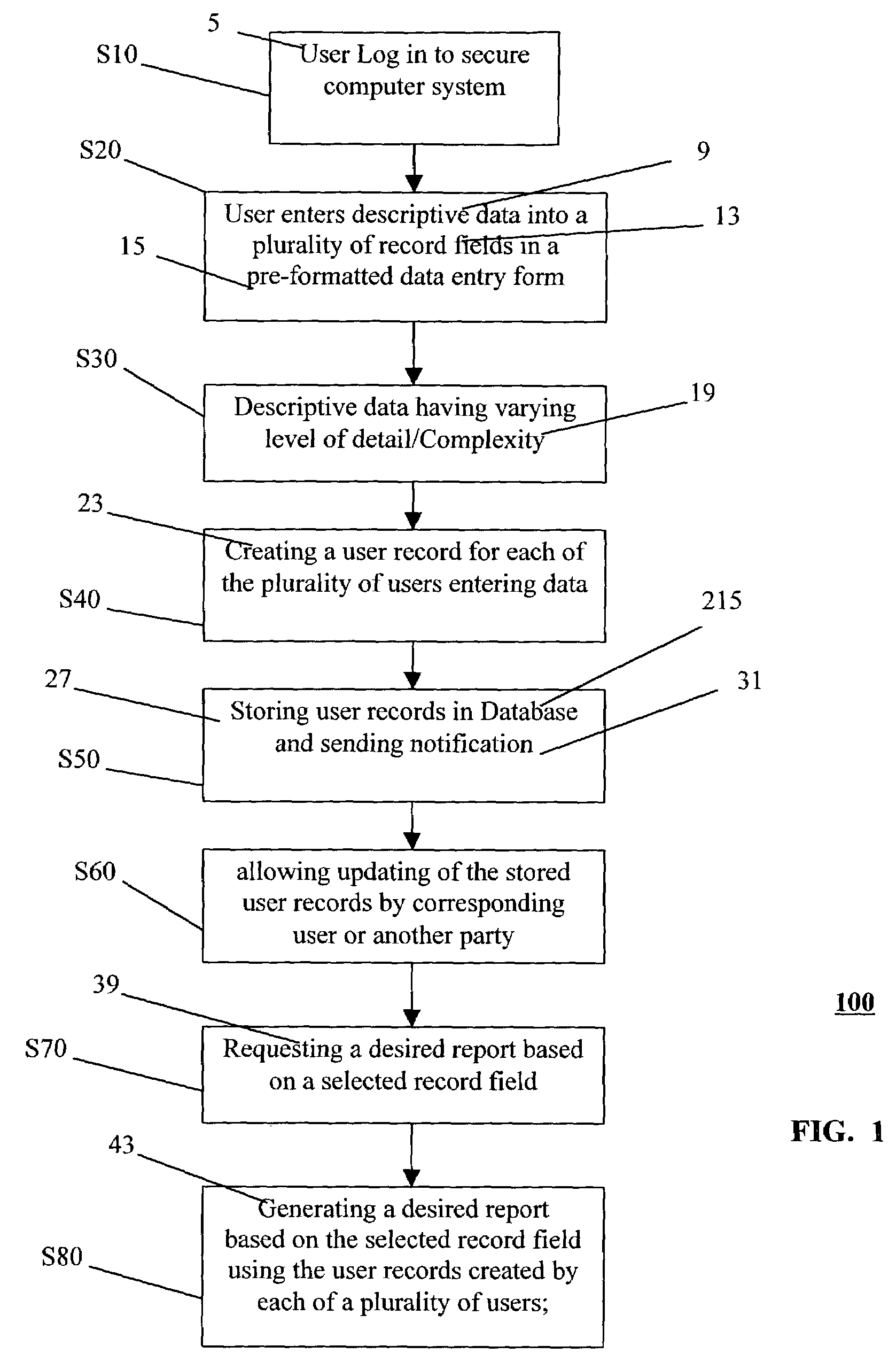

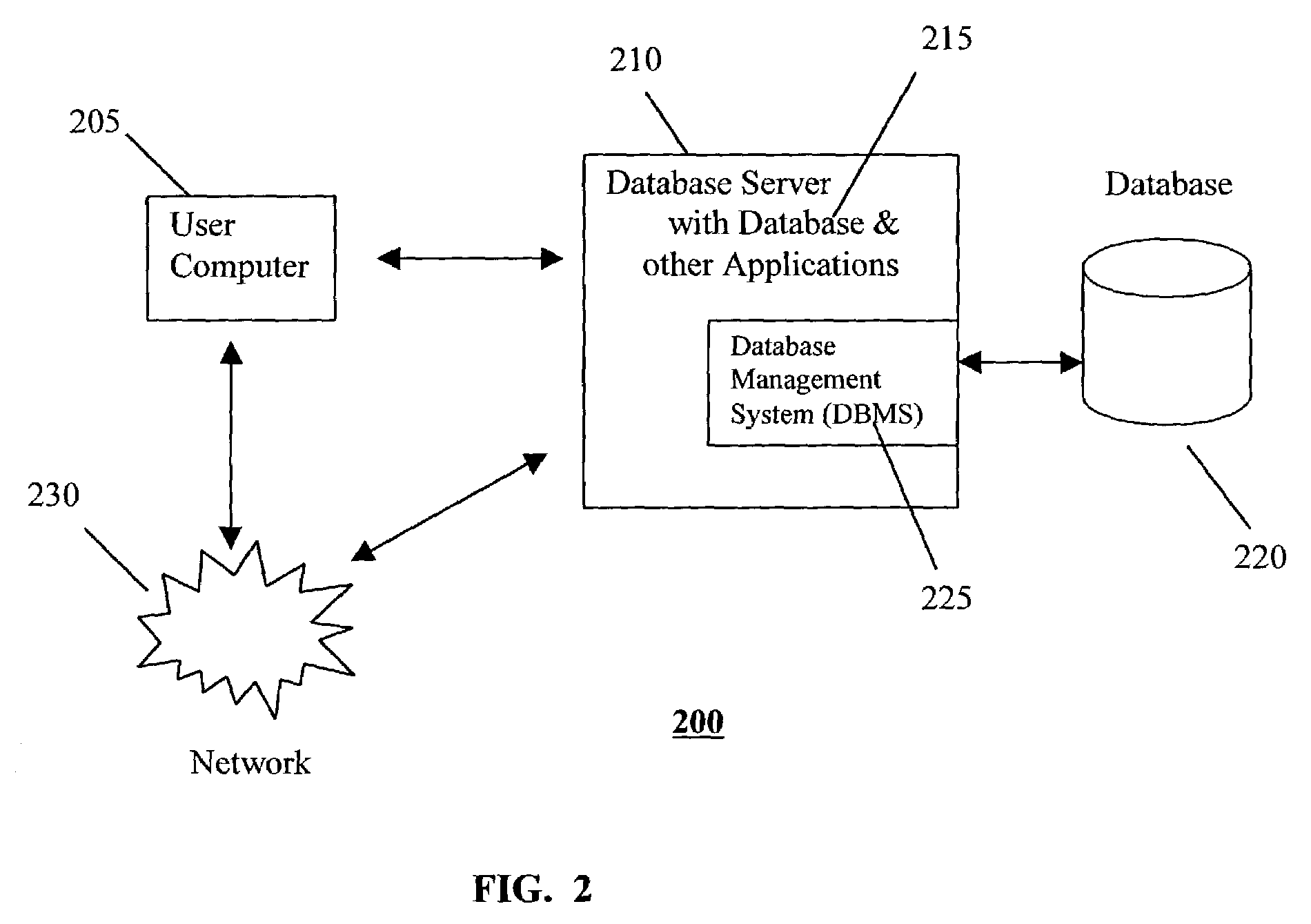

Method and system for automated generation of a requested report in a computer system

InactiveUS7113933B1Generate efficientlyValuable resource timeOffice automationResourcesComputerized systemCentral database

There is provided a method and system for efficiently generating administrative reports in an automated manner and for enabling users, who contributing to the reports, to create and store task, goal, progress and performance related descriptions, of varying complexity and detail, in a central database location from which appropriate task, goal and progress descriptions can be selectively retrieved for use in a desired periodic report for use in workload and performance management. This method and system frees up full time employees from the time consuming work of repeatedly preparing descriptions and information for workload and performance reports and substantially eliminates rework for administrative assistant who often consolidate and compile reports.

Owner:AMERIPRISE FINANCIAL

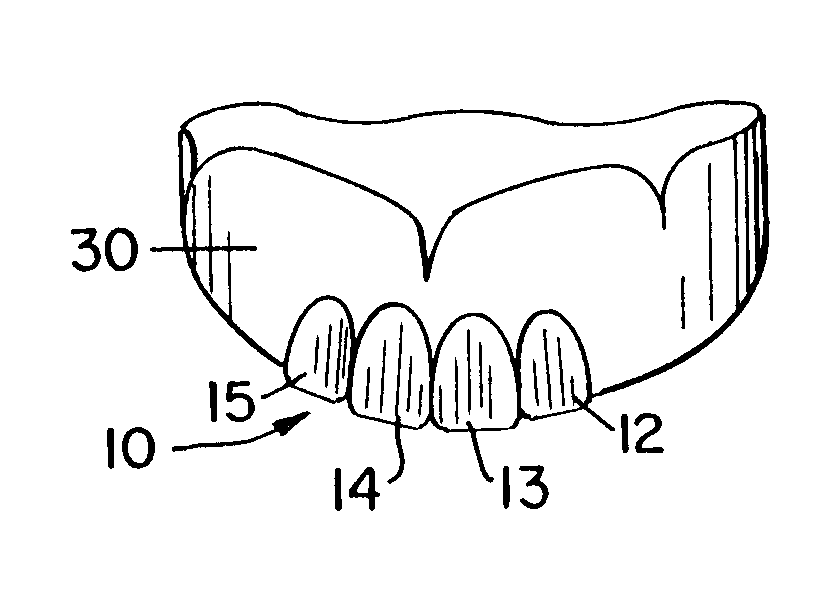

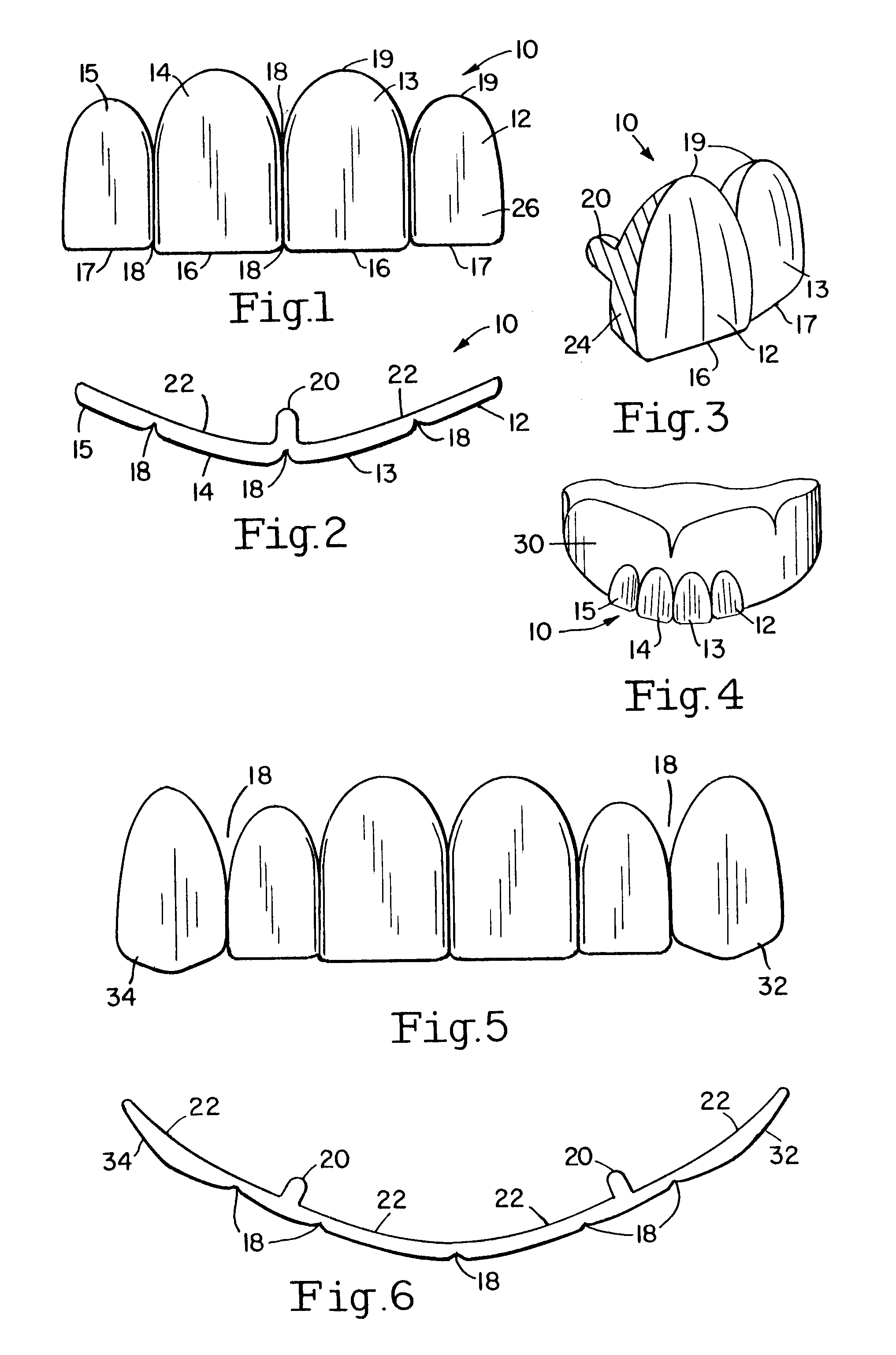

Facial registration tool

InactiveUS6422864B1The process is simple and effectiveImprove efficiencyImpression capsDenturesLingual surface

A facial registration tool for use in the fabrication of dental prostheses includes two or more interconnected artificial teeth and a retention means extending posteriorly from the lingual surface of the teeth for attaching the tool to a wax bite rim. In one embodiment the facial registration tool includes simulated upper left and right lateral and central incisors and a retention knob for mounting the tool to a bite rim.

Owner:GLATT MARC J

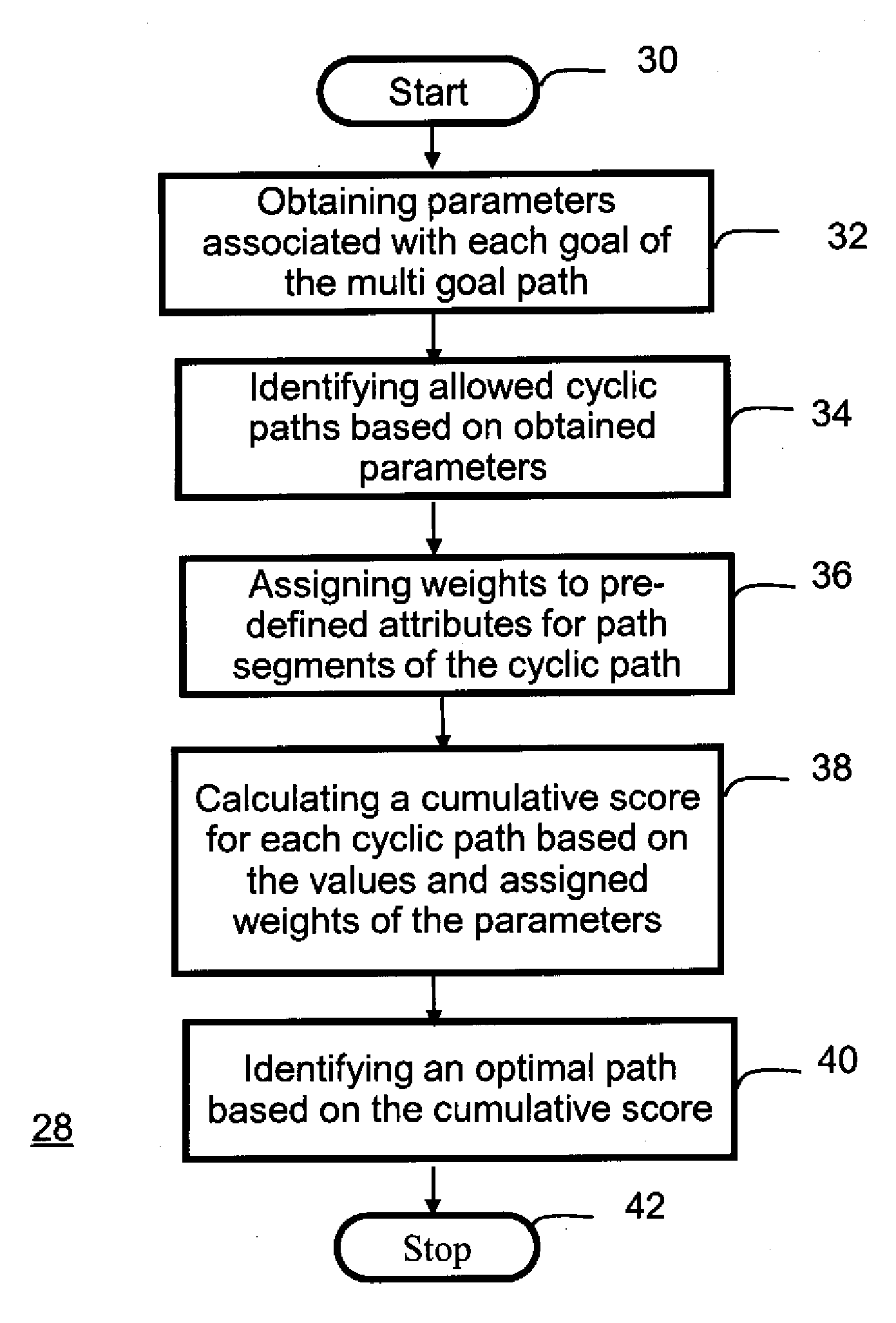

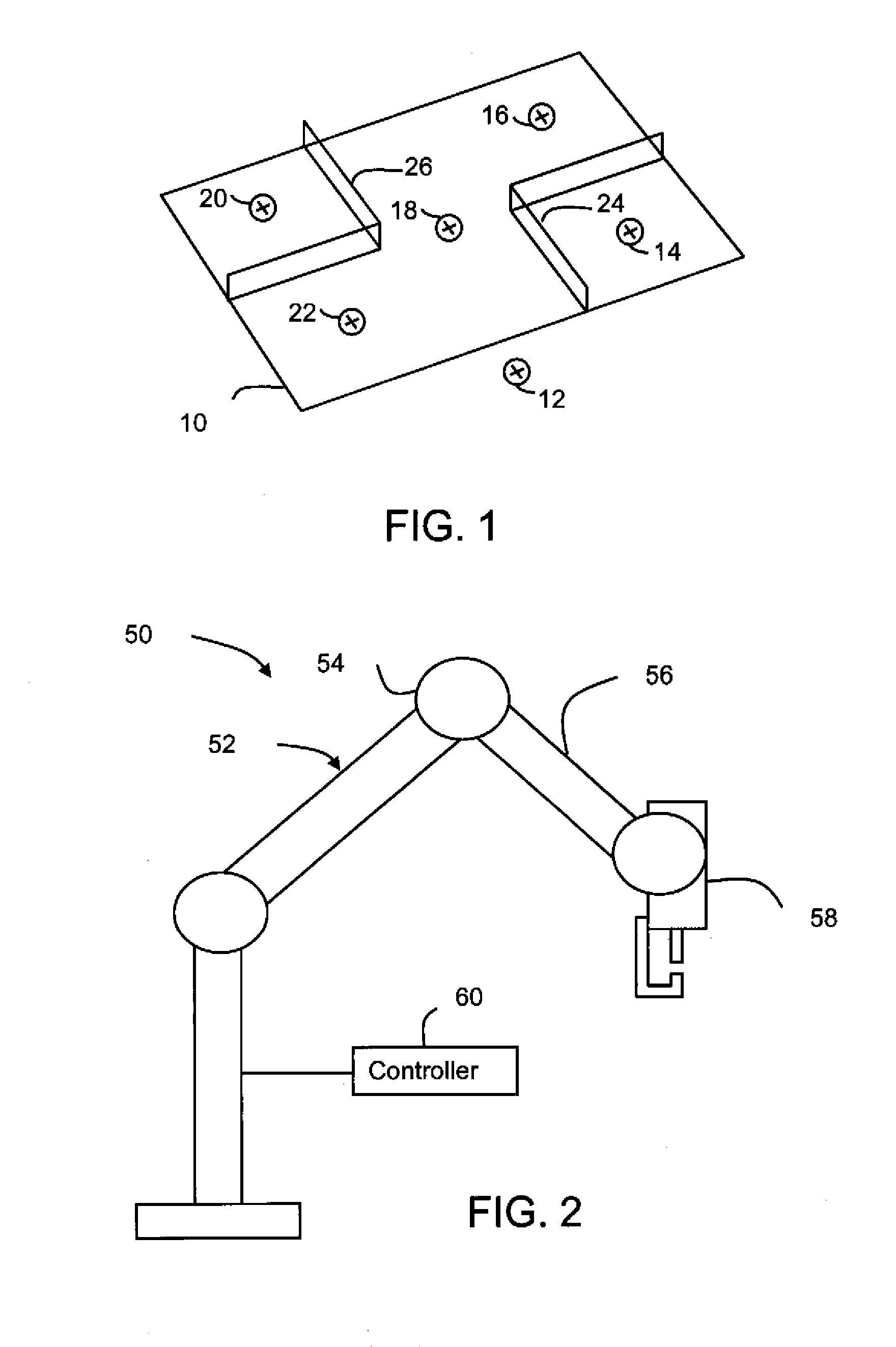

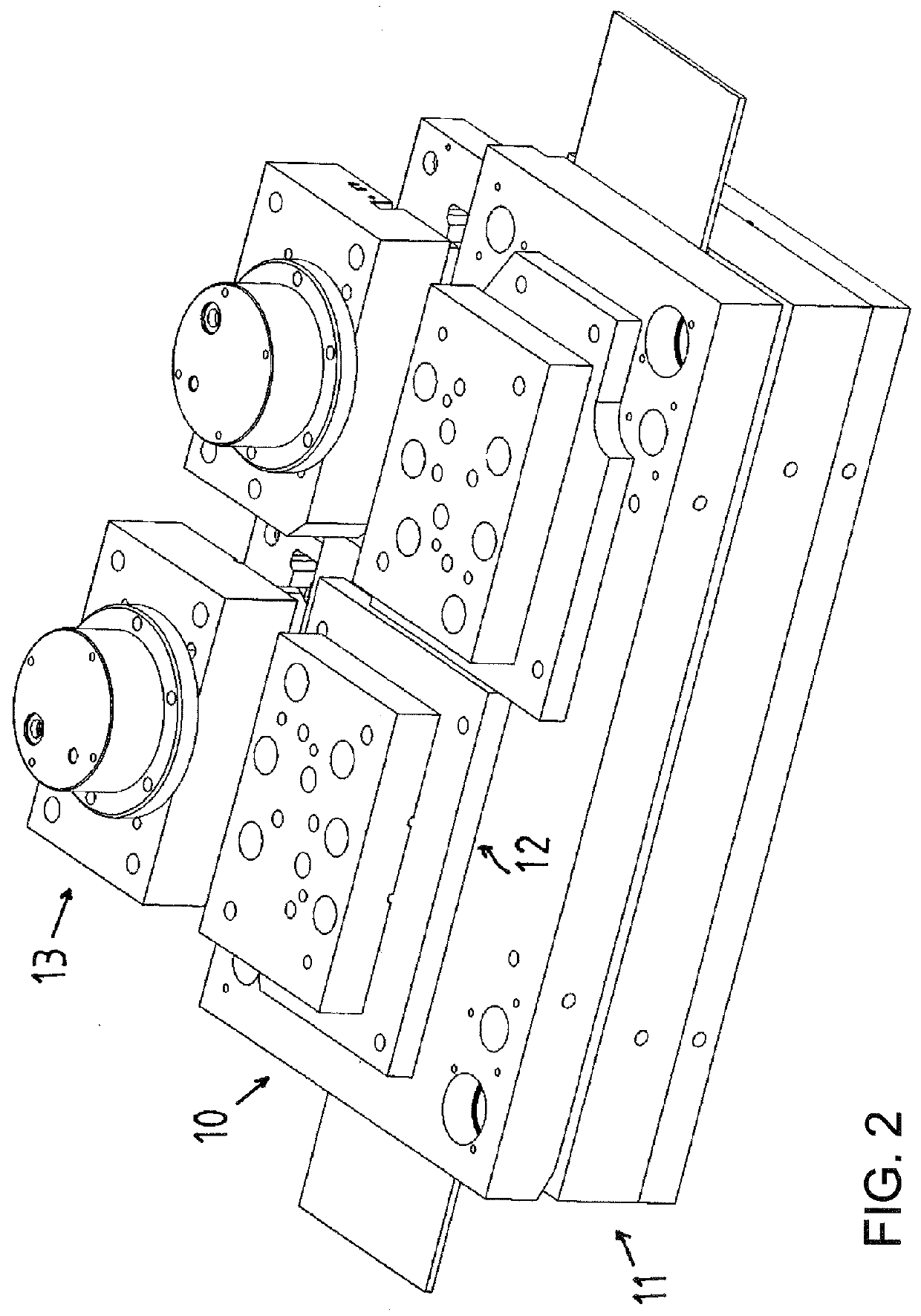

Multi-goal path planning of welding robots with automatic sequencing

InactiveUS20100114338A1Rapid determinationShorten cycle timeProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringRobot

A system and method for multi-goal path planning of welding robots with automatic sequencing. Input parameters associated with a number of goal points are obtained. The robot is moved through the multiple goal points based on the obtained inputs. One or more allowed cyclic paths are identified based on the obtained inputs. Weights are assigned to pre-defined attributes for path segments for each of the allowed cyclic paths. A cumulative score based on the values and assigned weights of the pre-defined attributes is calculated. An optimal path for the movement of robot across the goal points is identified based on the cumulative score.

Owner:GM GLOBAL TECH OPERATIONS LLC

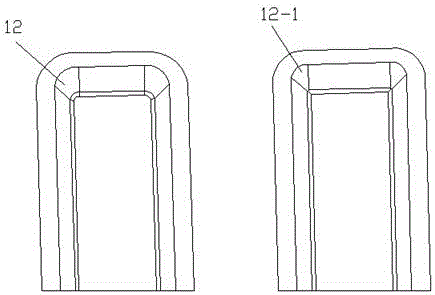

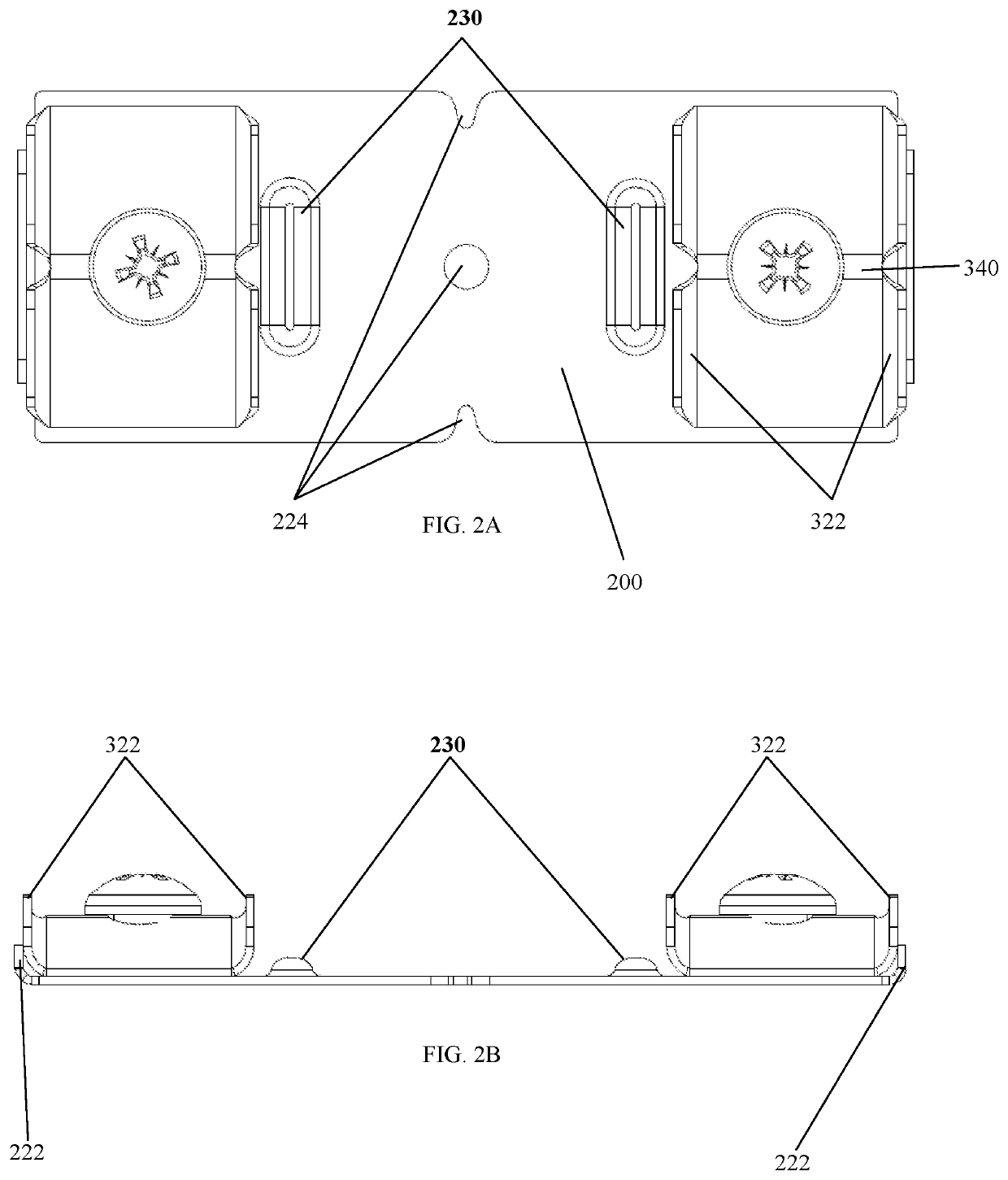

Restraint anchorage for a child restraint system

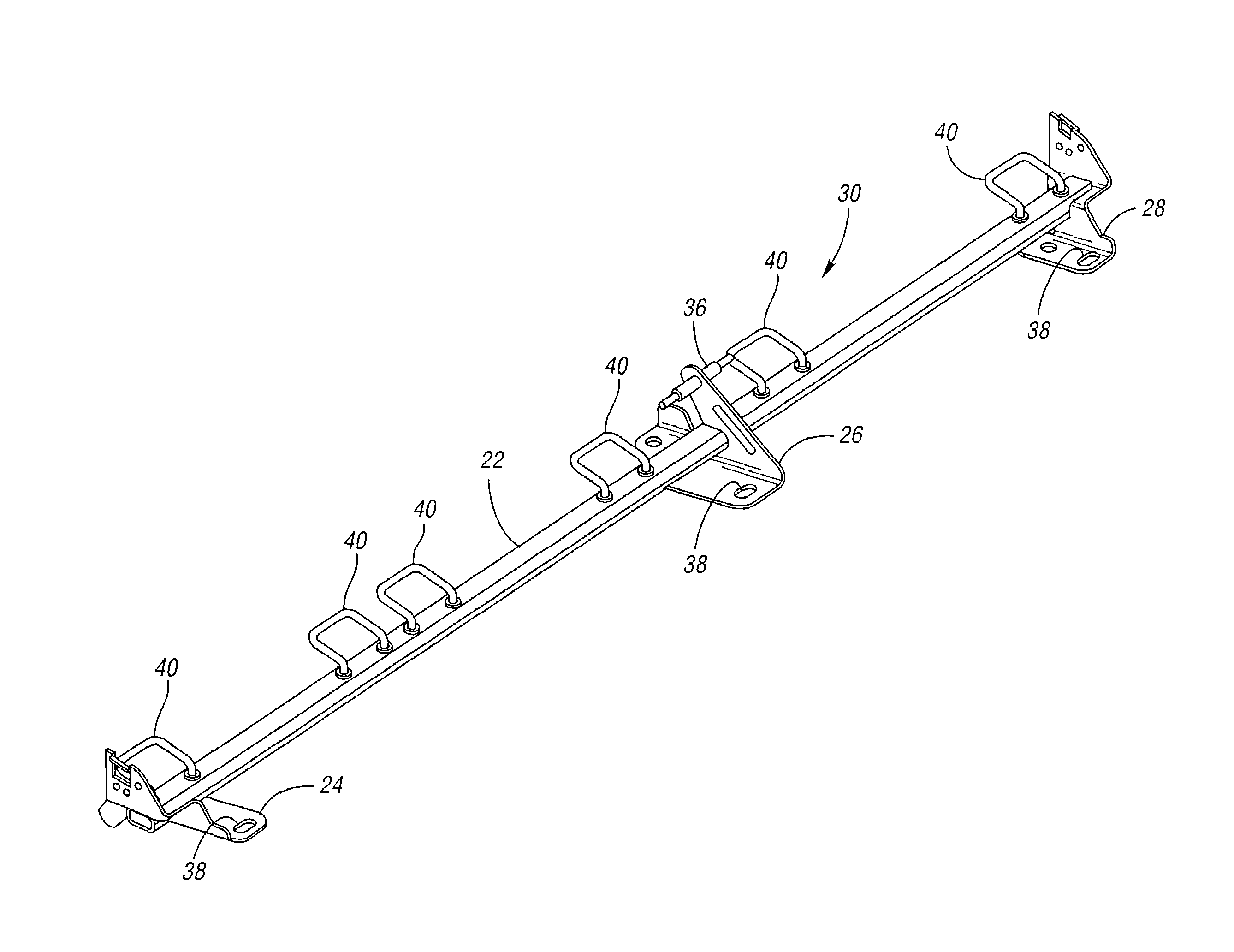

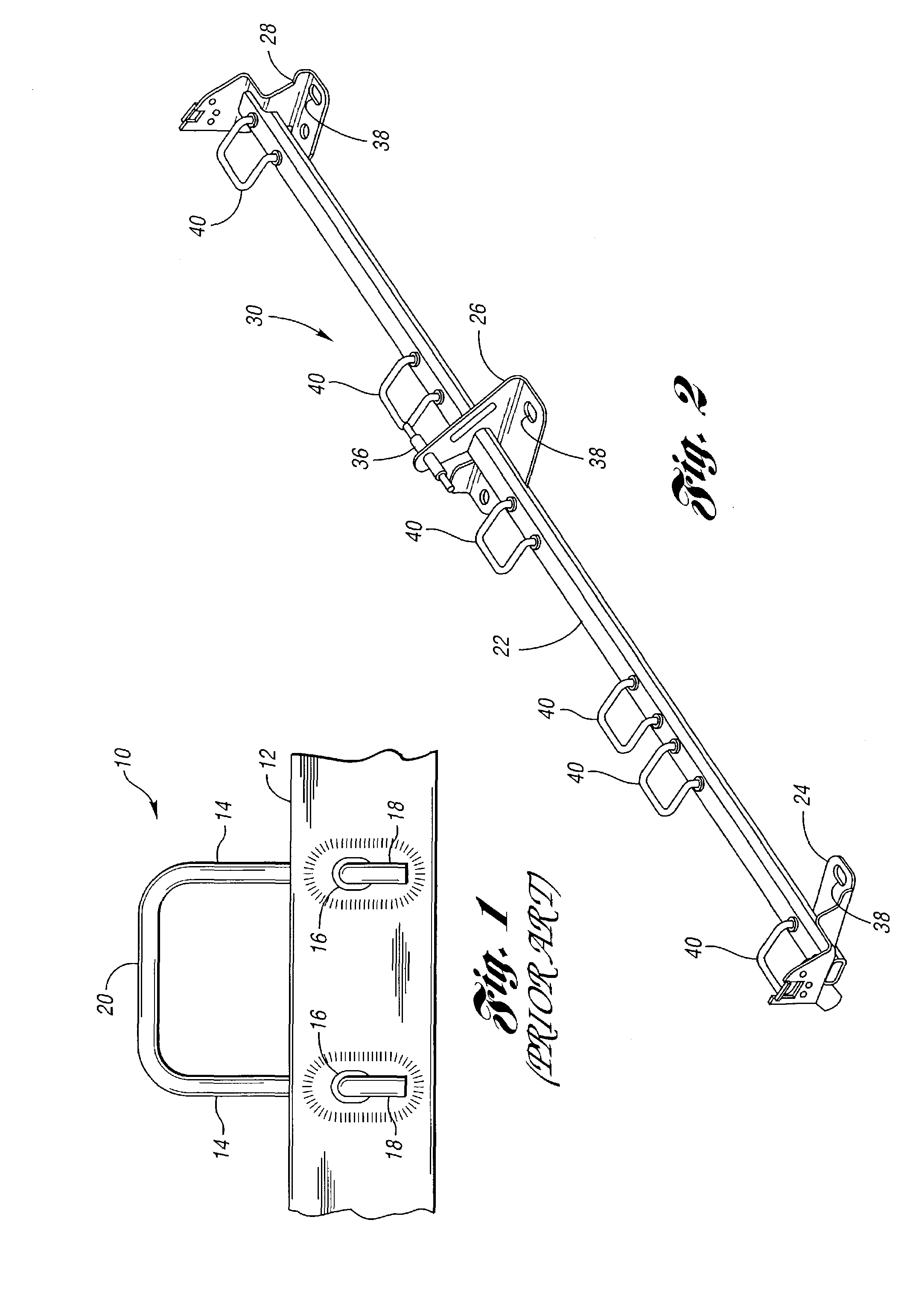

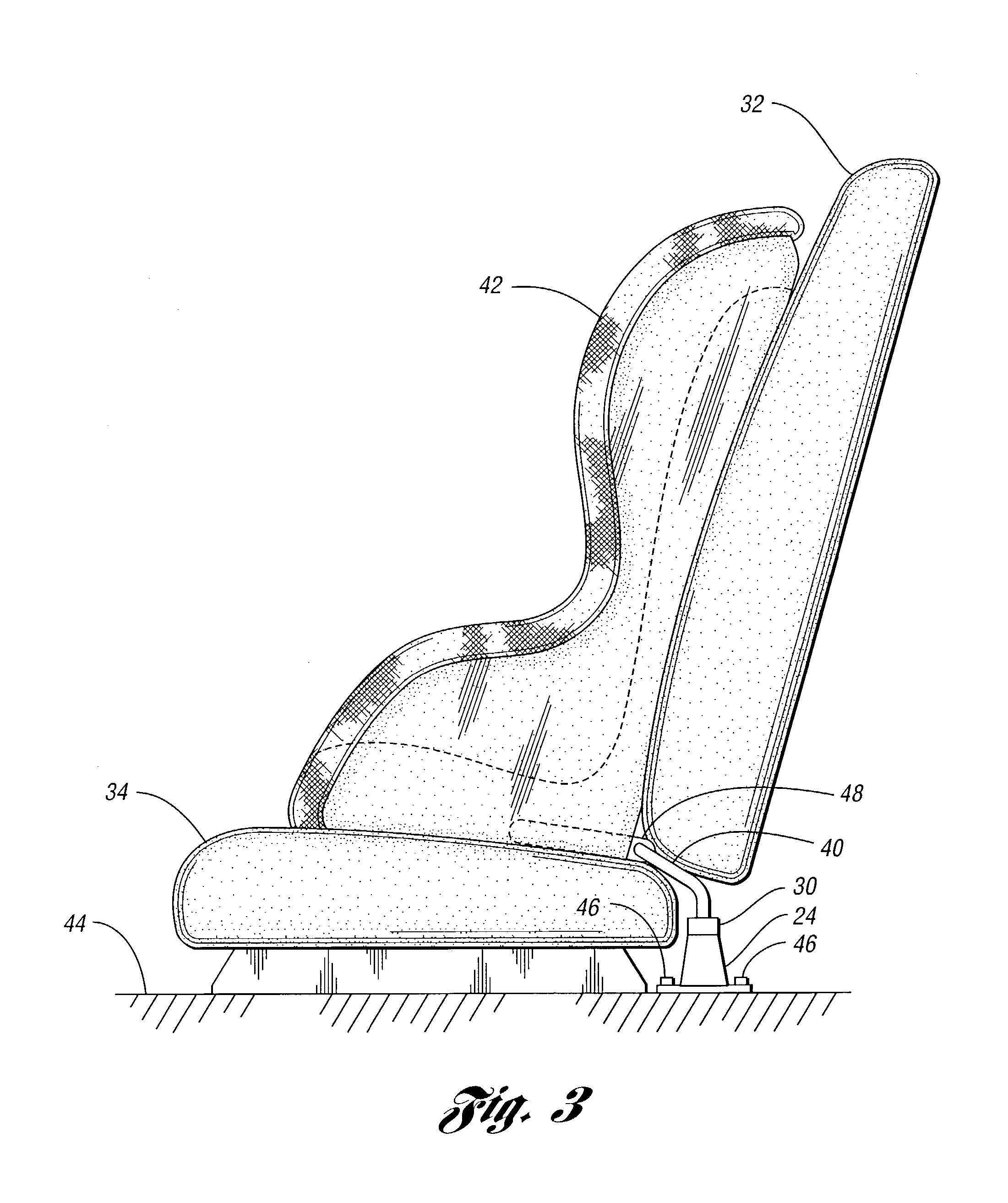

InactiveUS7131693B2Eliminate weldsImprove quality controlKids chairsStowing appliancesMobile vehicleChild restraint

A restraint anchorage for a child safety seat for an automotive vehicle having a cross member disposed behind the vehicle's seat. U-shaped latch wires are attached to the cross member. Collars are provided on the legs of the latch wires which engage one side of the cross members. The ends of the legs which protrude through holes provided in the cross member are peened over to form enlarged heads locking the latch wire to the cross member.

Owner:MAGNA CLOSURES INC

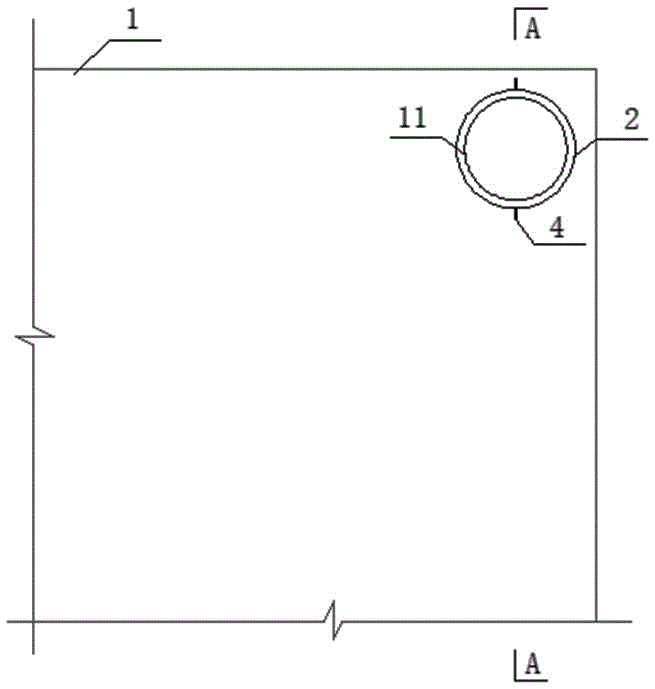

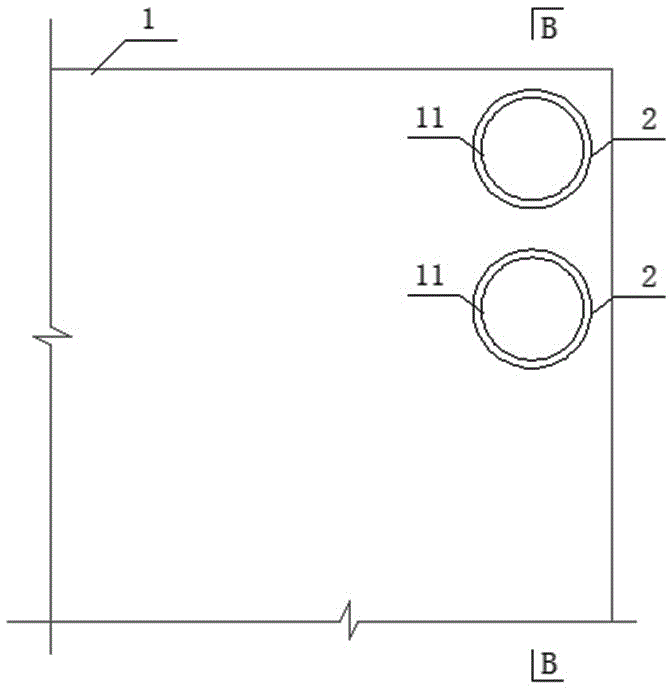

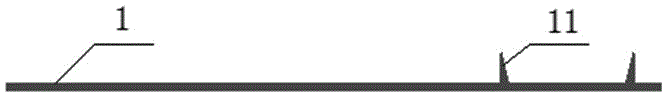

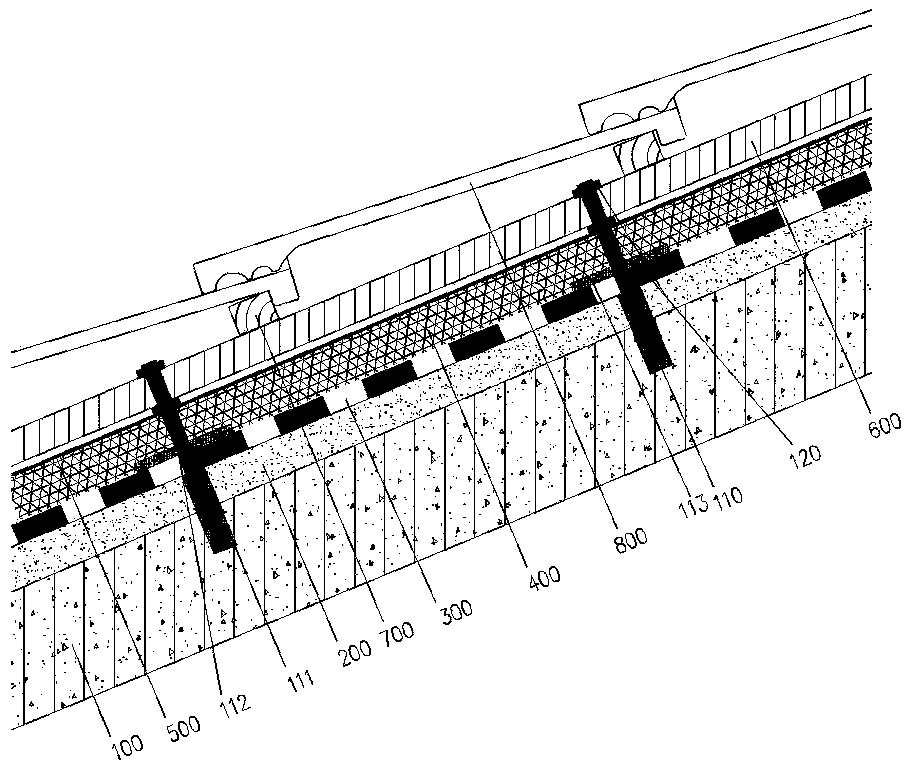

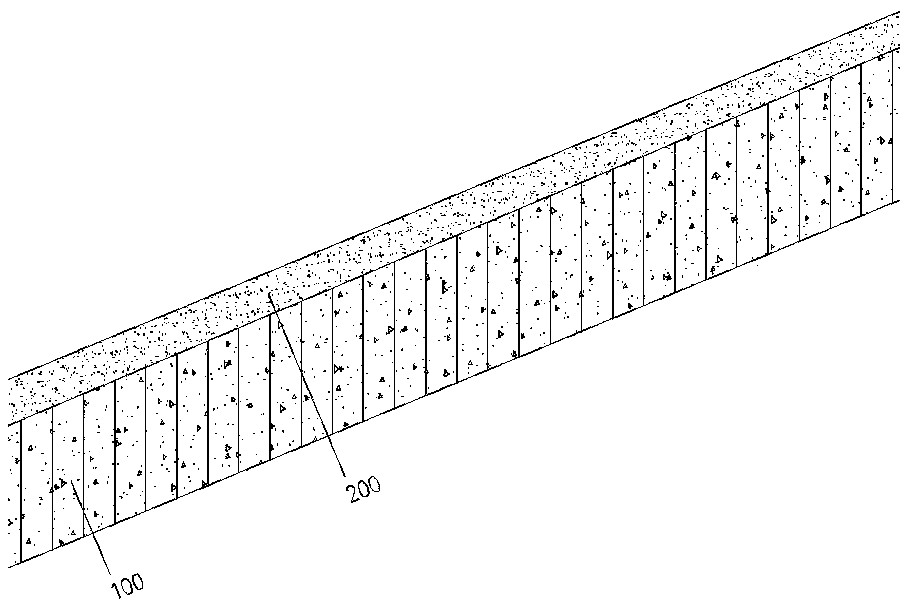

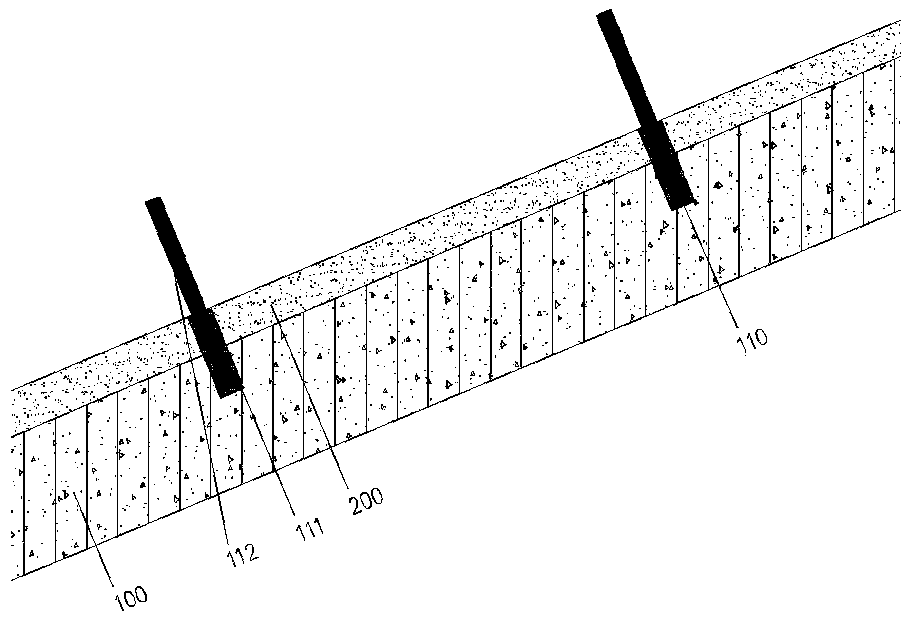

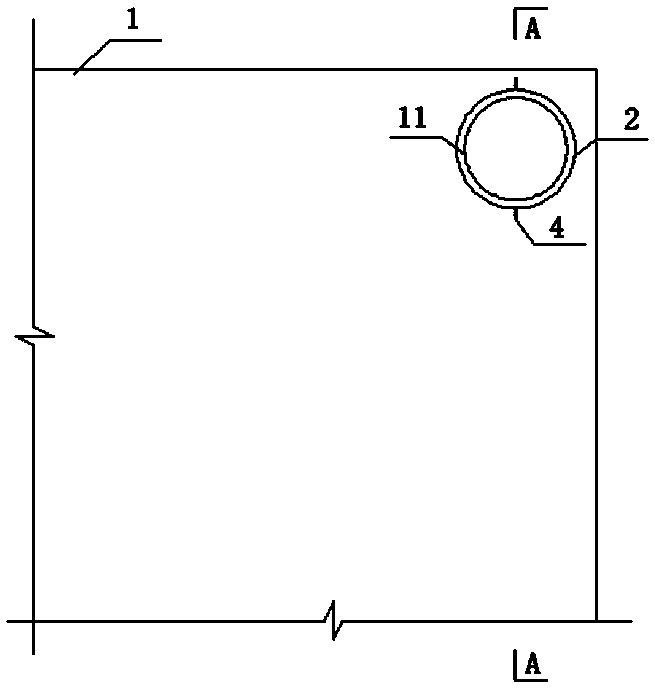

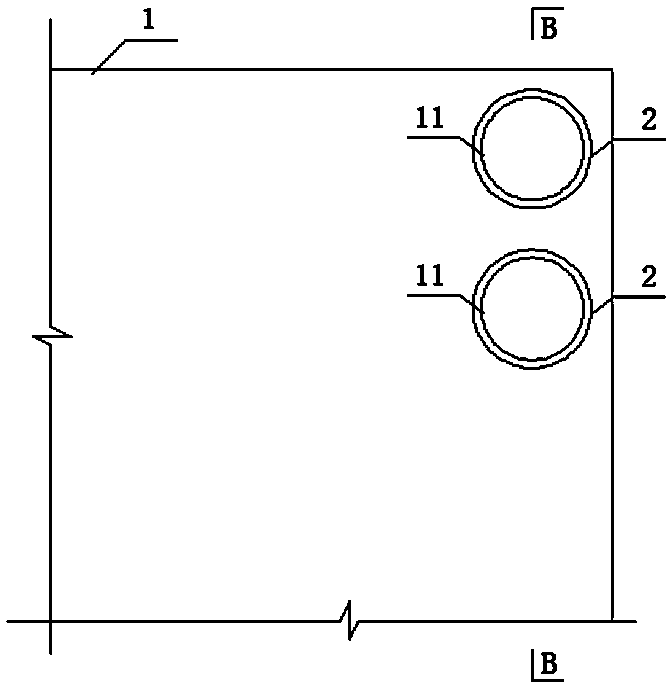

Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

ActiveCN106481880AGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesStructure of the EarthProduction drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

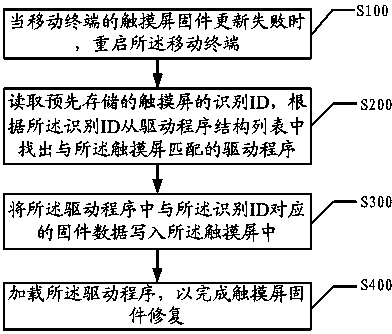

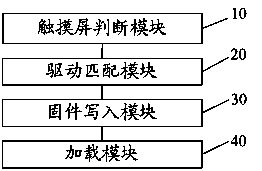

Mobile terminal touch screen firmware restoration method and device

ActiveCN103823723AResolve failureEliminate reworkFault responseSoftware engineeringRestoration methodComputer terminal

The invention discloses a mobile terminal touch screen firmware restoration method and device. The method includes when a touch screen firmware of a mobile terminal is failed to update, restarting the mobile terminal; reading a pre-stored identifier of the touch screen, and finding out a drive program matching with the touch screen from a drive program structure list according to the identifier; writing firmware data corresponding to the identifier in the drive program into the touch screen; loading the drive program to complete touch screen firmware restoration. Thus, when the mobile terminal is restarted, the touch screen with damaged firmwares can be restored automatically, repairing and returning of the firmwares caused by updating is eliminated, quality of products is improved, and great convenience is brought to users.

Owner:璟瑞科技(西安)有限公司

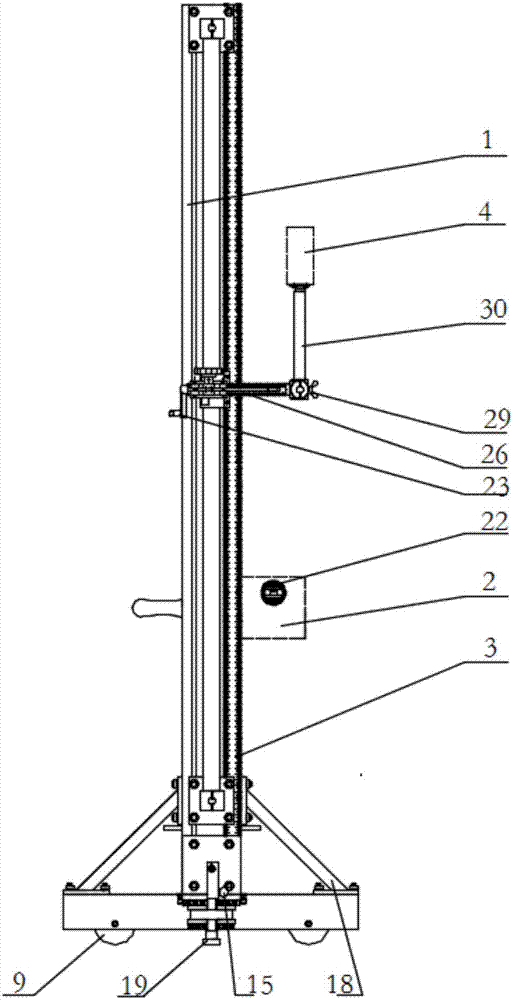

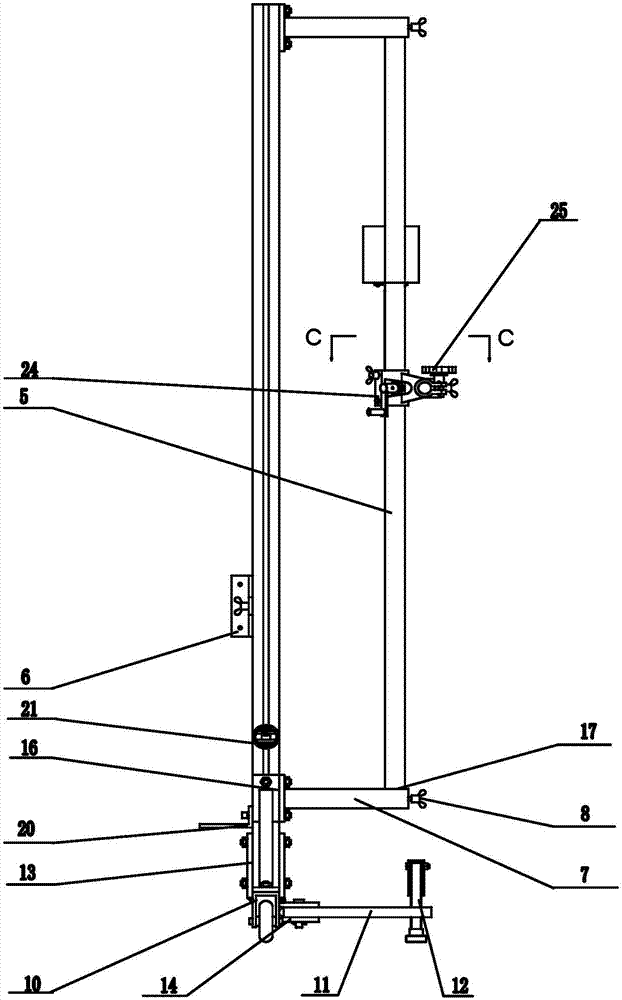

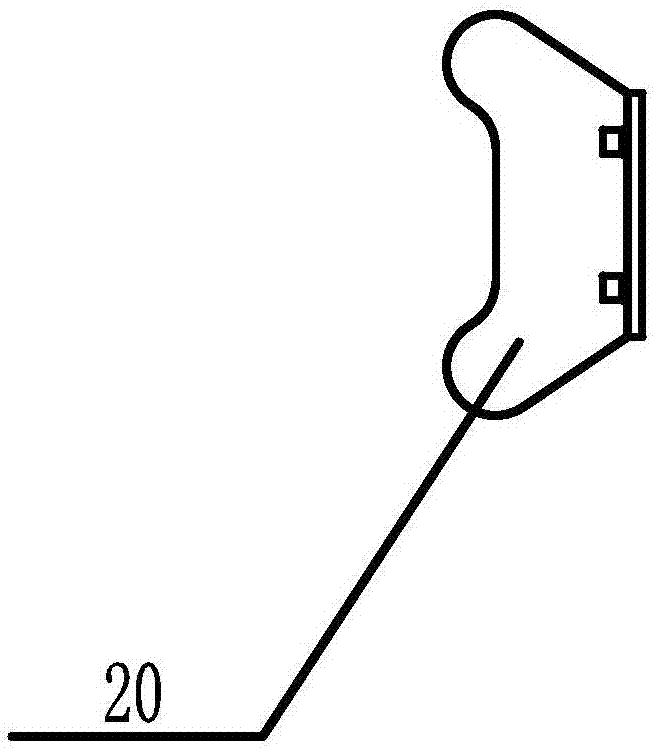

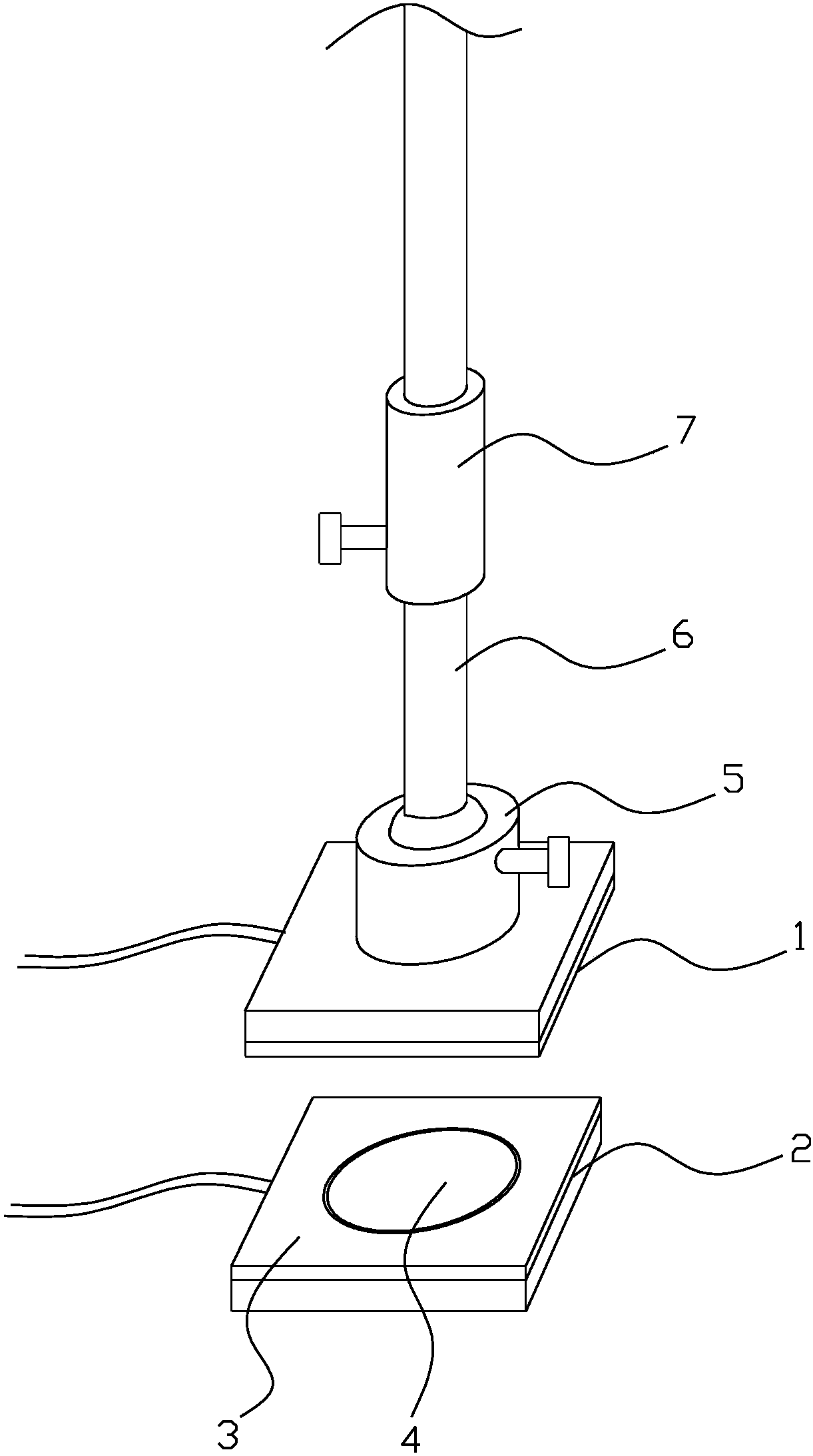

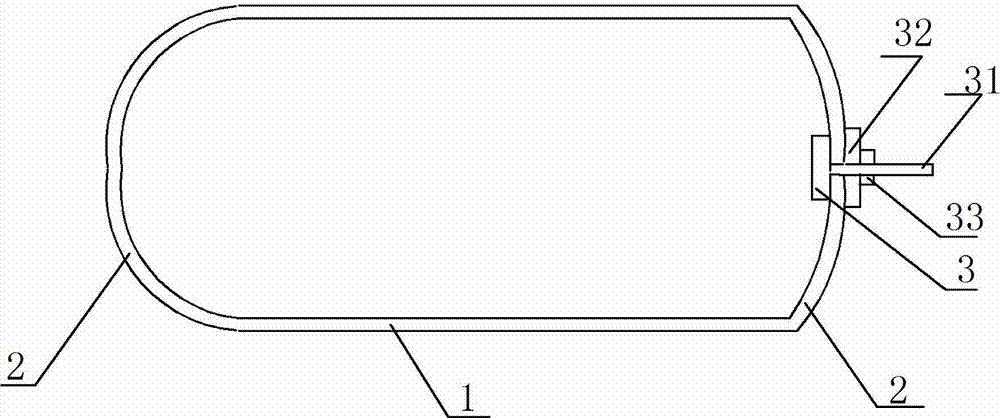

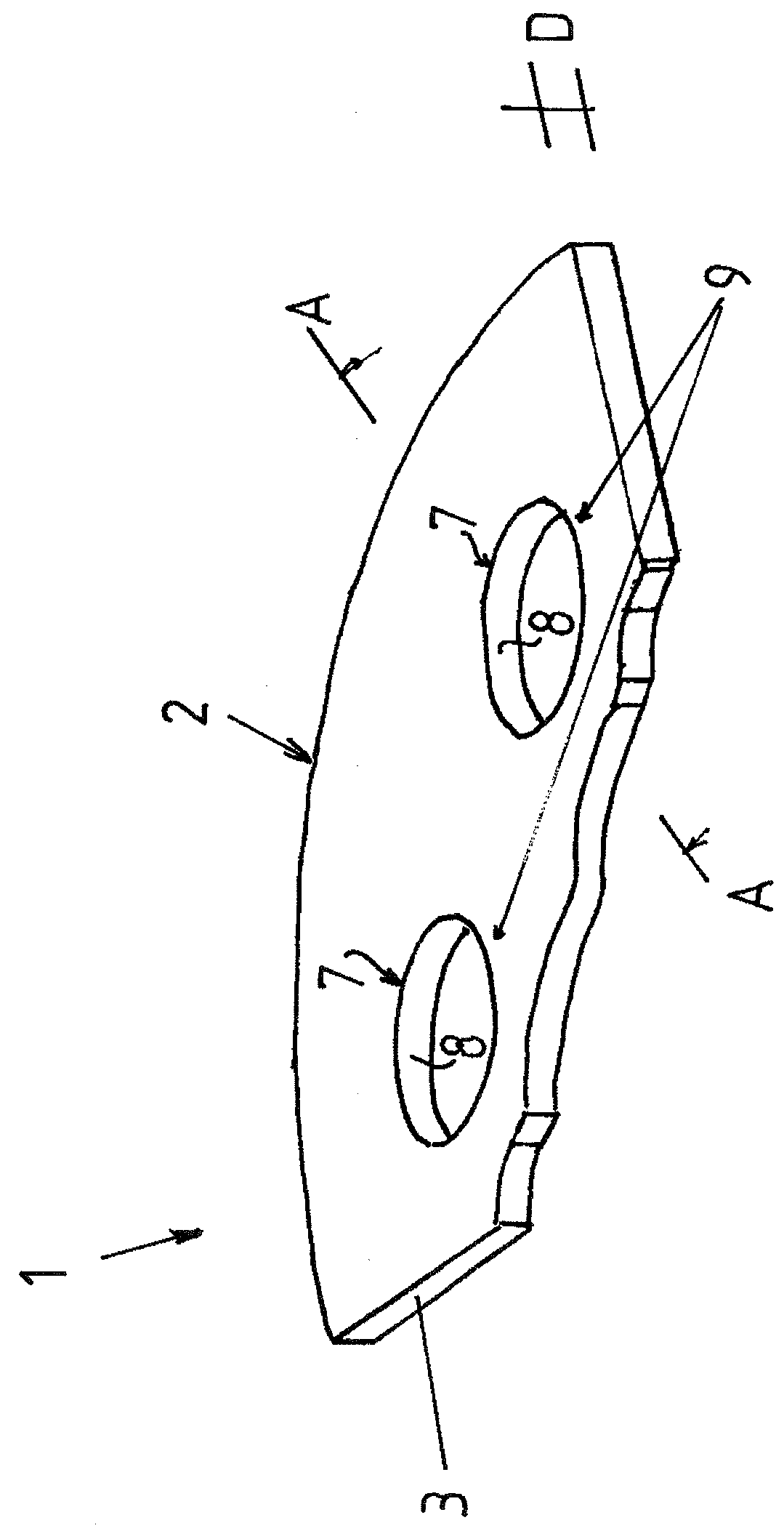

Curved surface positioning device

ActiveCN107192382AHigh positioning accuracyEasy to operateOptical rangefindersReference line/planes/sectorsLaser rangingEngineering

The invention provides a curved surface positioning device which comprises a base, a plumb rod, a laser range finder, a vertical graduated scale, a laser scribing instrument, a height regulation rod and a height regulation mechanism; the plumb rod and the vertical graduated scale are fixed on the base and are arranged in parallel; the laser range finder is fixed on the plumb rod; the upper end and the lower end of the height regulation rod are fixed on the plumb rod through connection rods respectively; the height regulation mechanism is arranged on the height regulation rod in a sliding manner; the laser scribing instrument is fixed on the height regulation mechanism; and the height of the laser scribing instrument is regulated by the height regulation mechanism. The curved surface positioning device is simple to operate, can perform accurate positioning or scribing on curved surfaces of various vehicles without measurement, can completely put an end to occurrence of reworking and improves the operation efficiency.

Owner:CRRC TANGSHAN CO LTD

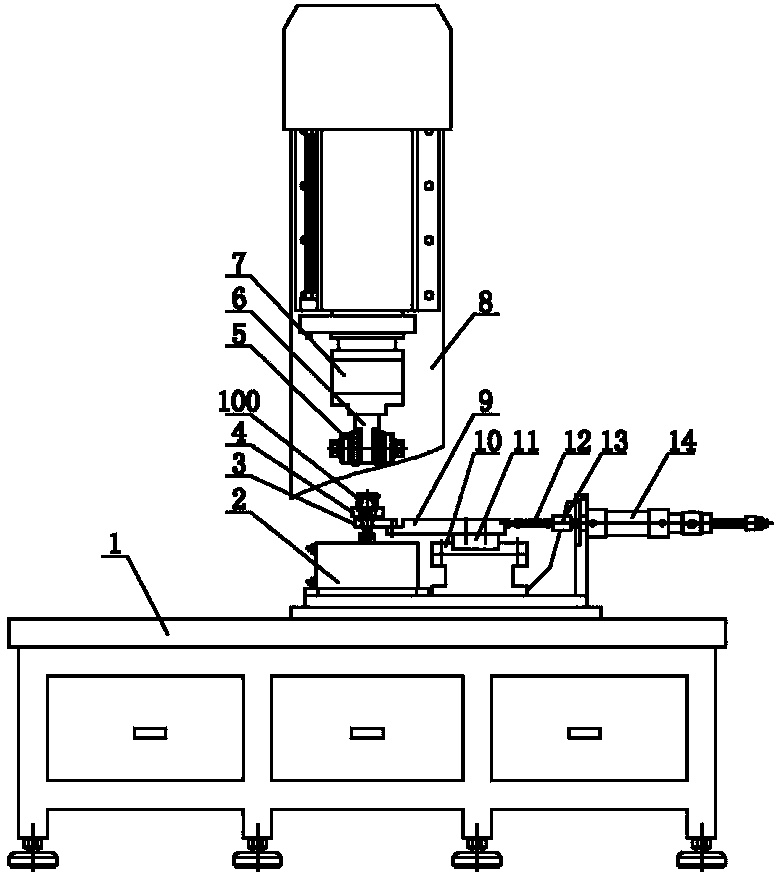

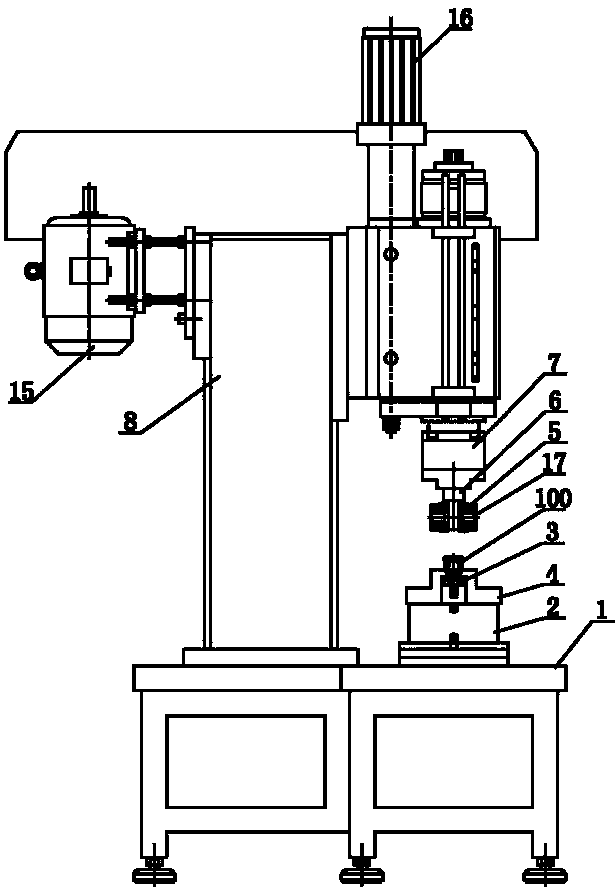

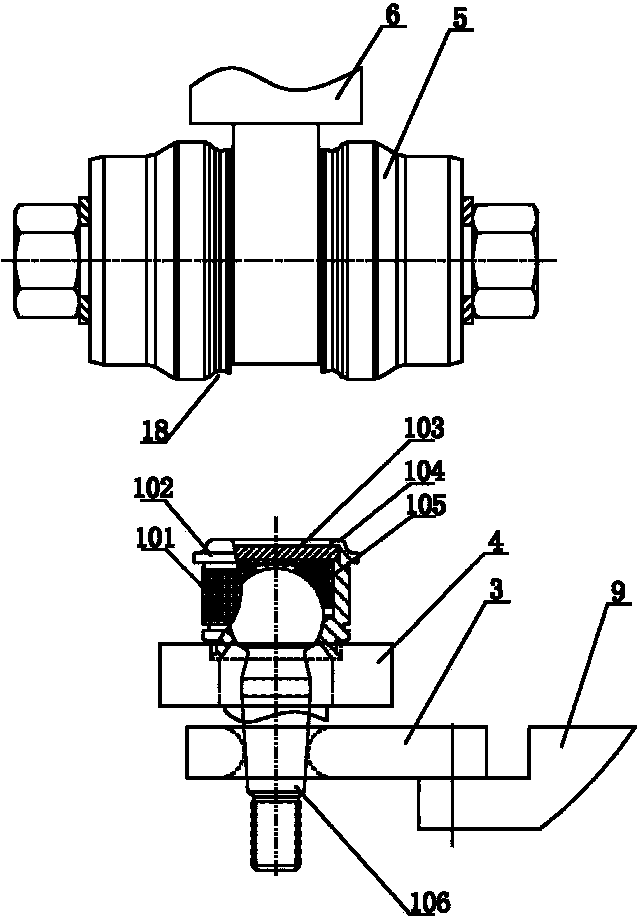

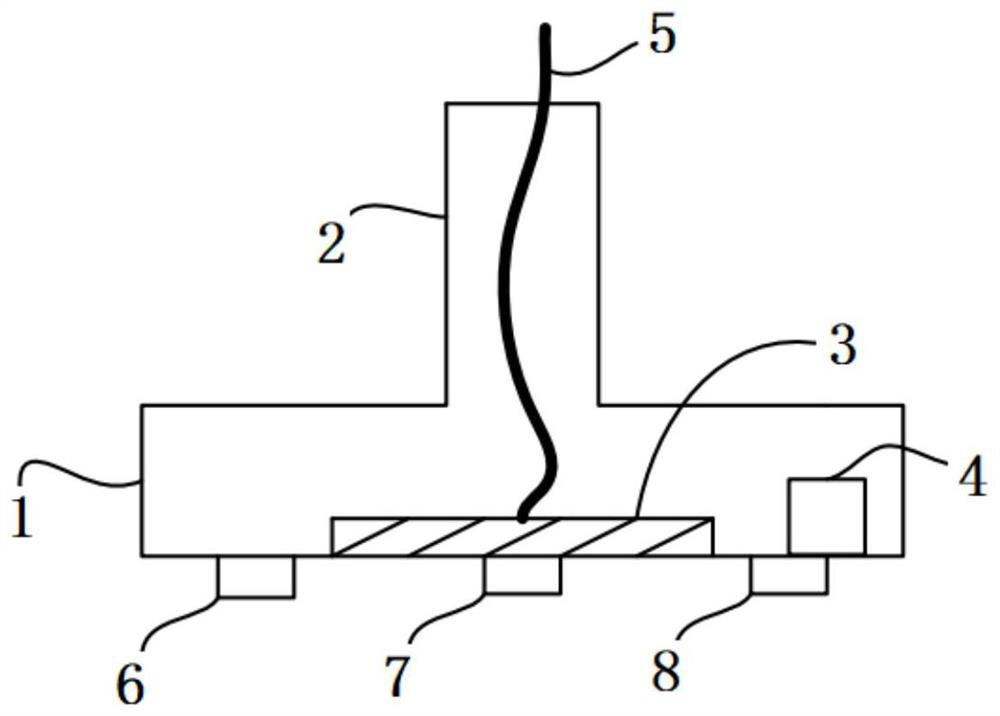

Machine tool special for riveting globe joint

ActiveCN104191204AReduce manufacturing costIncrease productivityWork measurementTorque measurementControl theoryMachine tool

The invention discloses a machine tool special for riveting a globe joint. The machine tool comprises an installation base, a riveting head and a power head, wherein the riveting head is arranged over the installation base, and the riveting head is connected to the bottom of the power head and driven by the power head to rotate. The machine tool is characterized by further comprising a servo motor and a torque detecting device, the servo motor pushes the power head and the riveting head to conduct vertical adjustment during working, the torque detecting device pushes a ball rod of a globe joint workpiece to swing in a leftward-rightward reciprocating mode during working, the torque detecting device comprises a positioning ring, a connecting plate, a torque sensor and a push-pull part, the positioning ring is used for buckling the ball rod of the globe joint workpiece, one end of the connecting plate is connected with the positioning ring, the other end of the connecting plate is connected with the torque sensor, the other end of the torque sensor is connected with the push-pull part, and the output end of the torque sensor is electrically connected with the servo motor. By the adoption of the machine tool, the driving torque requirement of the globe joint workpiece can be met as soon as the globe joint workpiece is riveted and assembled, production efficiency is improved, reworking of products is avoided, and production cost is saved.

Owner:ZHEJIANG LIFUDE MACHINERY

Asphalt concrete pavement 3D paving construction method

InactiveCN108049291AShorten construction timeEliminate reworkRoads maintainenceLaser transmitterControl system

The invention relates to an asphalt concrete pavement 3D paving construction method. The method includes the following steps that construction is prepared; a construction segment is determined; a three-dimensional digital model of the construction segment is established; laser emitter control points are distributed; design elements of a paved face are determined, and the longitudinal slope of a paved region and the design elevation of a paved belt start point are calculated according to design requirements; laser emitters are installed according to the position of a paved belt, the design elements of the to-be-paved region are input into the laser emitters, and the paved face accuracy set in the laser emitters is detected and checked; a paver and paver parameters are established; the control points, paved face information and laser receiver and laser emitter data are input into a control system, and the control system determines the height of a distributor of the paver; and paving is organized to be implemented. By the adoption of the asphalt concrete pavement 3D paving construction method, the parameters such as the paving thickness, the paving width and the pavement elevation inthe asphalt concrete pavement paving construction process are accurately and automatically controlled.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

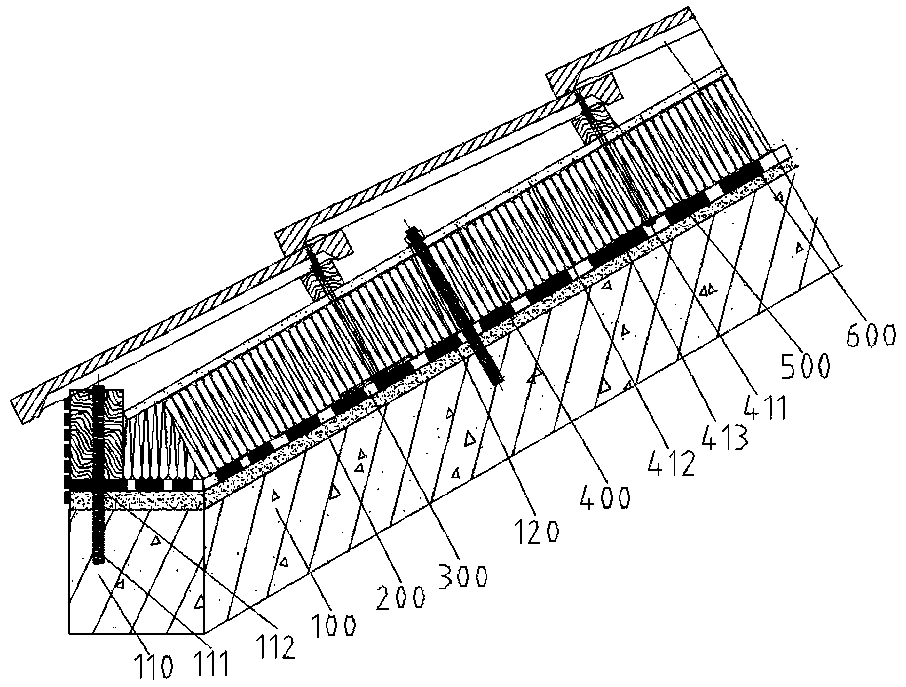

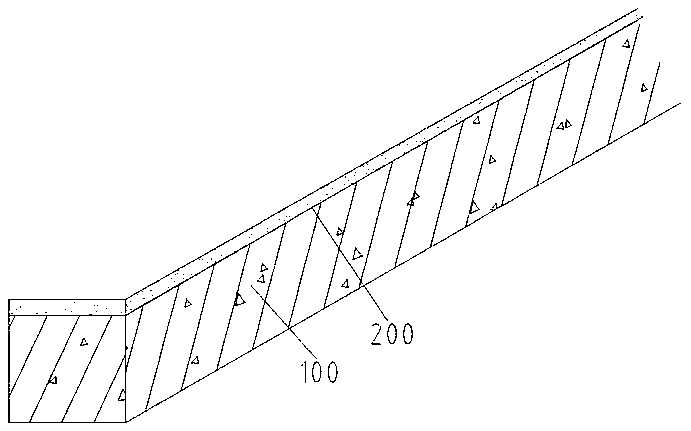

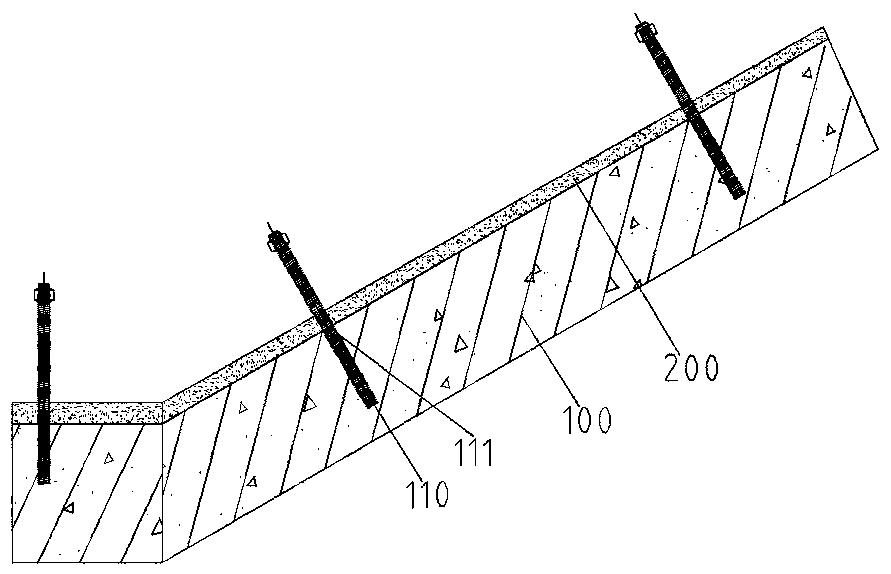

Roof heat preservation system structure

PendingCN108915163AEliminate reworkReduce material waste and labor lossBuild-up roofsRoof covering insulationsRebarSystem structure

The invention aims to disclose a roof heat preservation system structure, which comprises a reinforced concrete base layer and a mortar leveling layer laid on the reinforced concrete base layer, wherein pay-off embedded steel bars, a waterproof layer, a heat preservation layer, a protective layer and counter battens are sequentially arranged on the mortar leveling layer, roof battens are laid on the counter battens, hanging roof tiles are arranged on the roof battens, the counter battens are fixed on the protective layer through a metal bar structure and are levelled, and the protective layeris a mortar protective layer or an easy-to-coil material covering protective layer. Compared with the prior art, the roof heat preservation system structure has good waterproof effect, is suitable forconstruction of various modeling slope roofs, has good heat preservation performance, less wet operation and strong air convection, has effects of energy conservation and environment protection, greatly reduces the use of non-renewable or less-renewable resources, is an advocacy of green building engineering and achieves the objective of the present invention.

Owner:北京利泰装饰工程有限公司

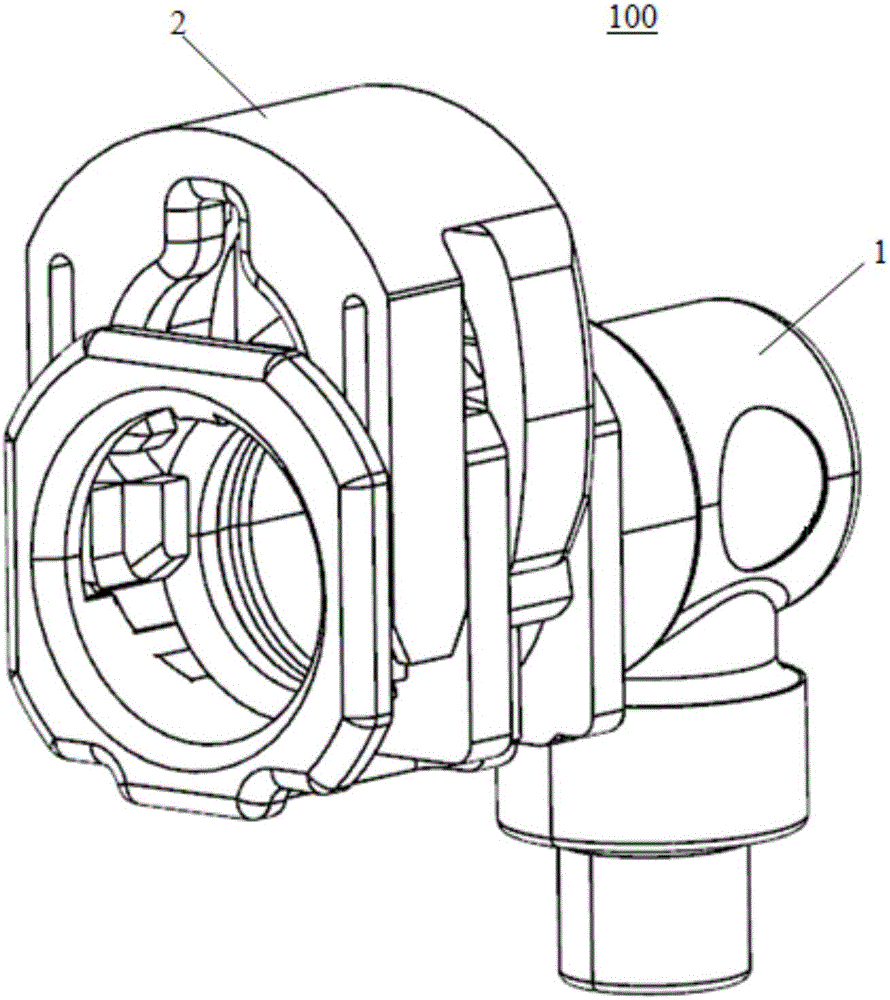

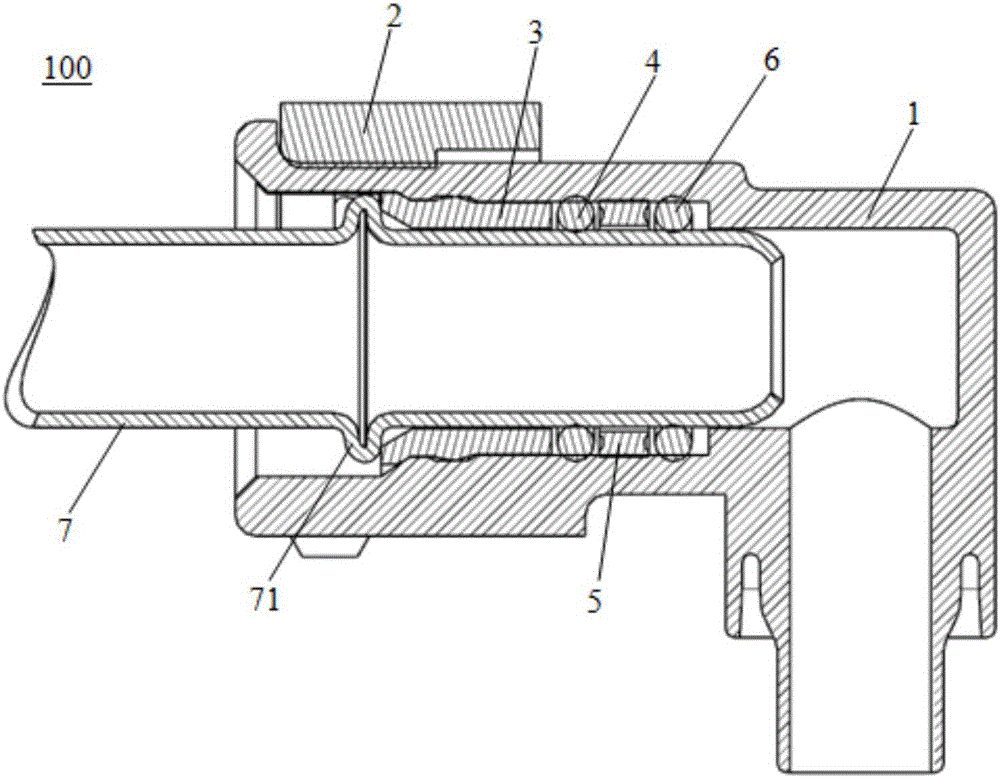

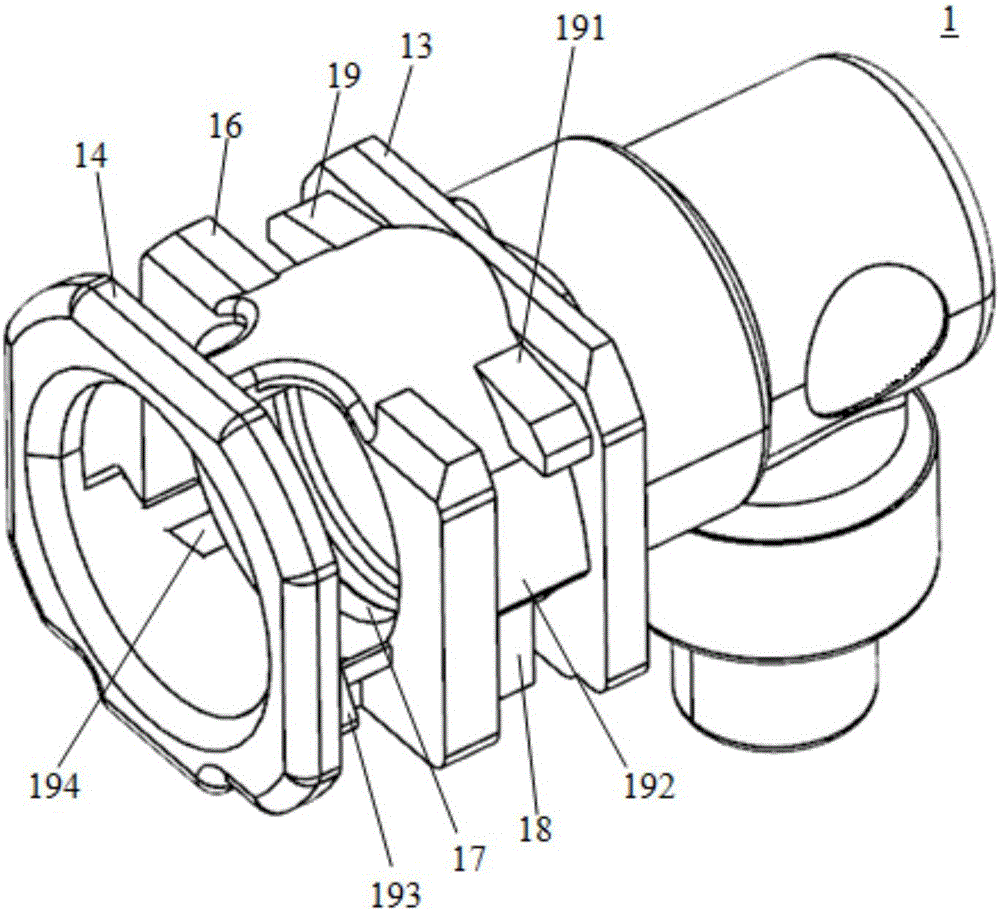

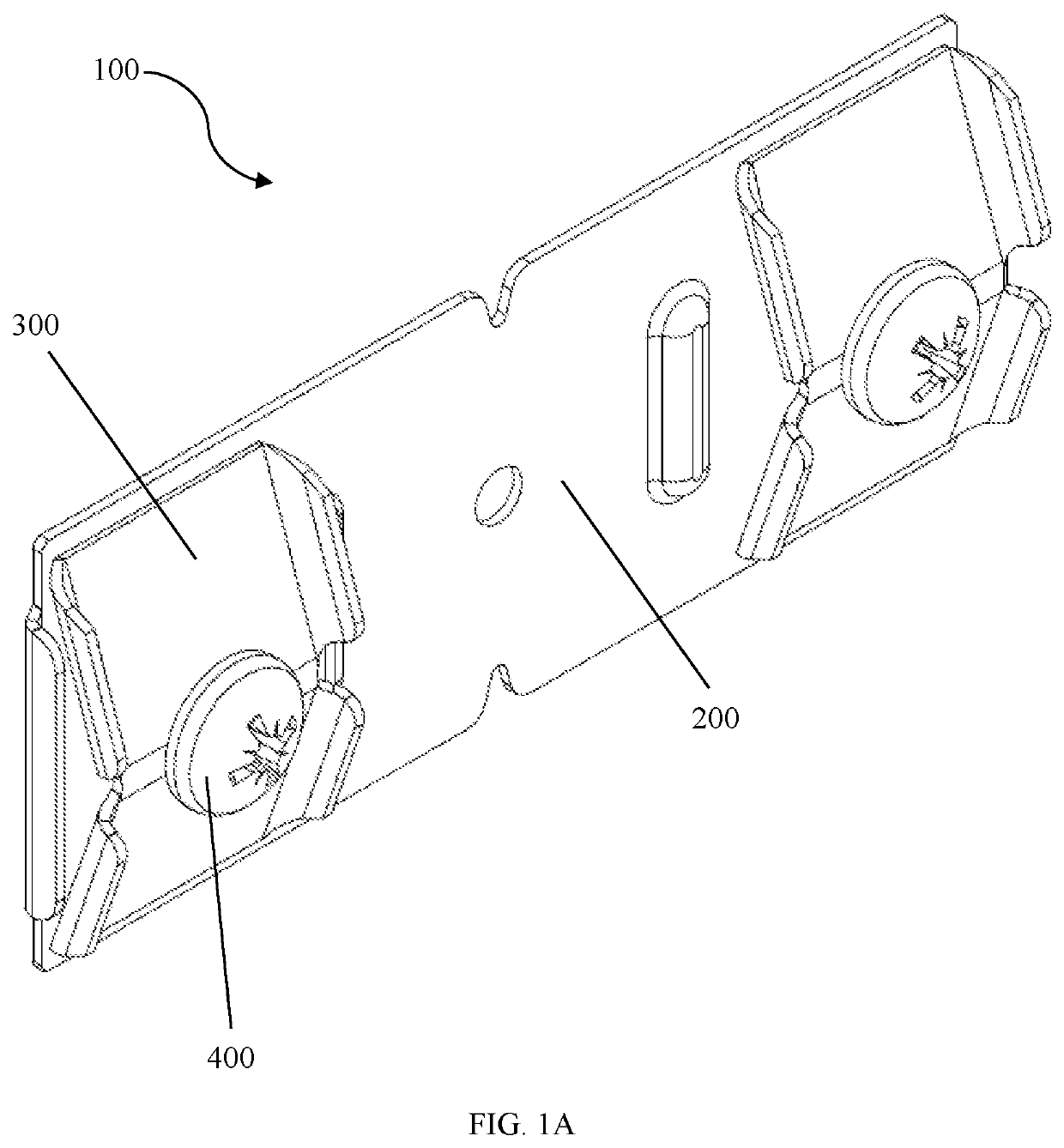

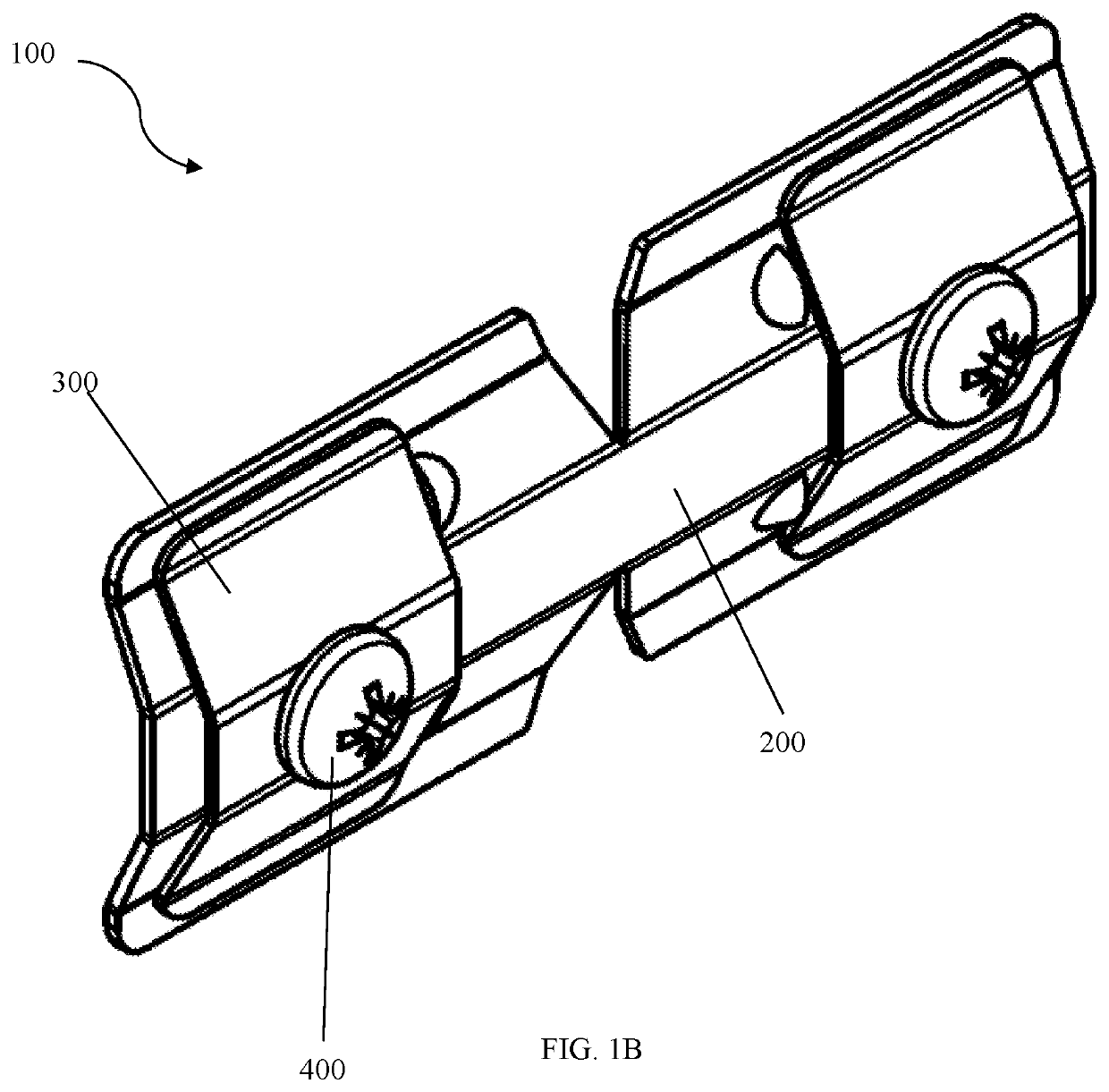

Fully-assembled quick connector

ActiveCN105003779APrevent pressingEliminate reworkCouplingsSpontaneous combustionConductive materials

The invention discloses a fully-assembled quick connector. The fully-assembled quick connector comprises a connector body and a locking snap joint in press-fit locking with the connector body, wherein the connector body comprises symmetrically arranged hollow through openings; the locking snap joint comprises first claw parts used for wrapping a butting pipeline and corresponding to the through openings, second claw parts located on the rear surfaces of the first claw parts and first lug bosses corresponding to the second claw parts; the distance between the claw openings of the first claw parts is smaller than that between the claw openings of the second claw parts; the width of the second claw parts corresponds to that of a lug boss on the butting pipeline. According to the fully-assembled quick connector, only when the butting pipeline is fully assembled in place, can the locking snap joint continually move downwards to be in press-fit with the connector body, so that security risks caused by the reason that the butting pipeline is not fully assembled are eliminated; the connector body made of a conductive material is designed to conduct static charge generated in the pipeline to the outside, so that the spontaneous combustion risk of a car due to accumulation of static charge is avoided.

Owner:COOPER STANDARD AUTOMOTIVE SUZHOU CO LTD

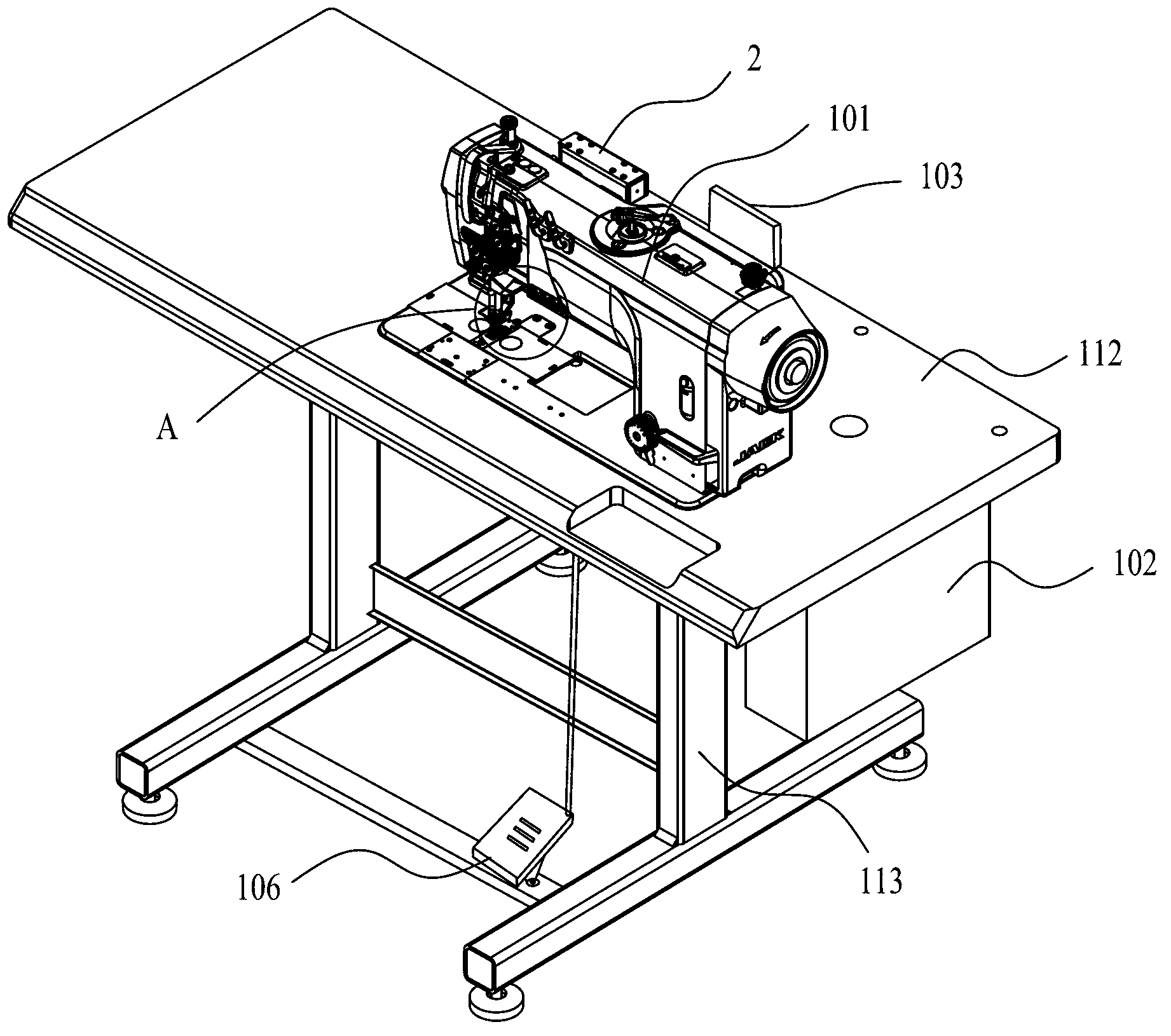

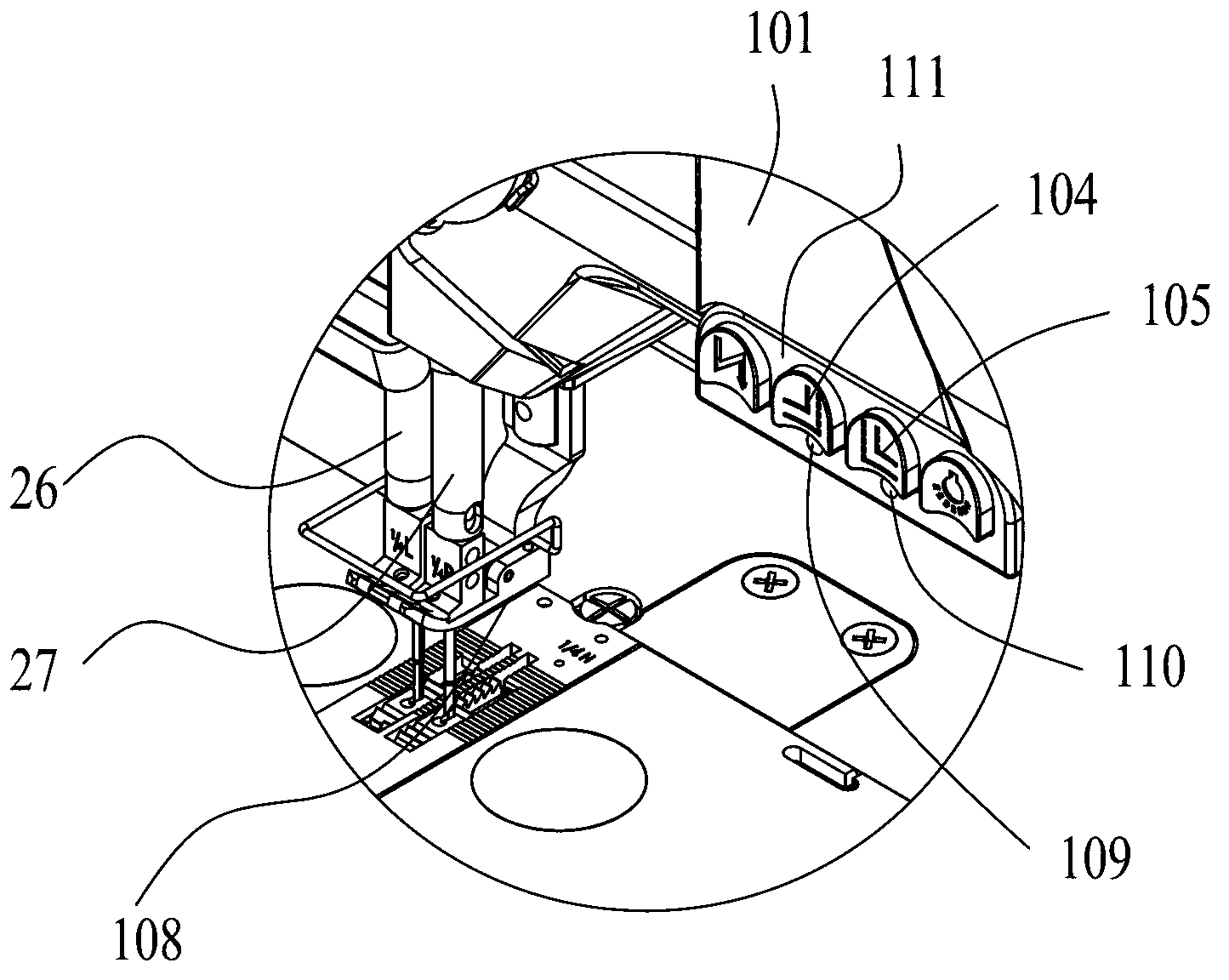

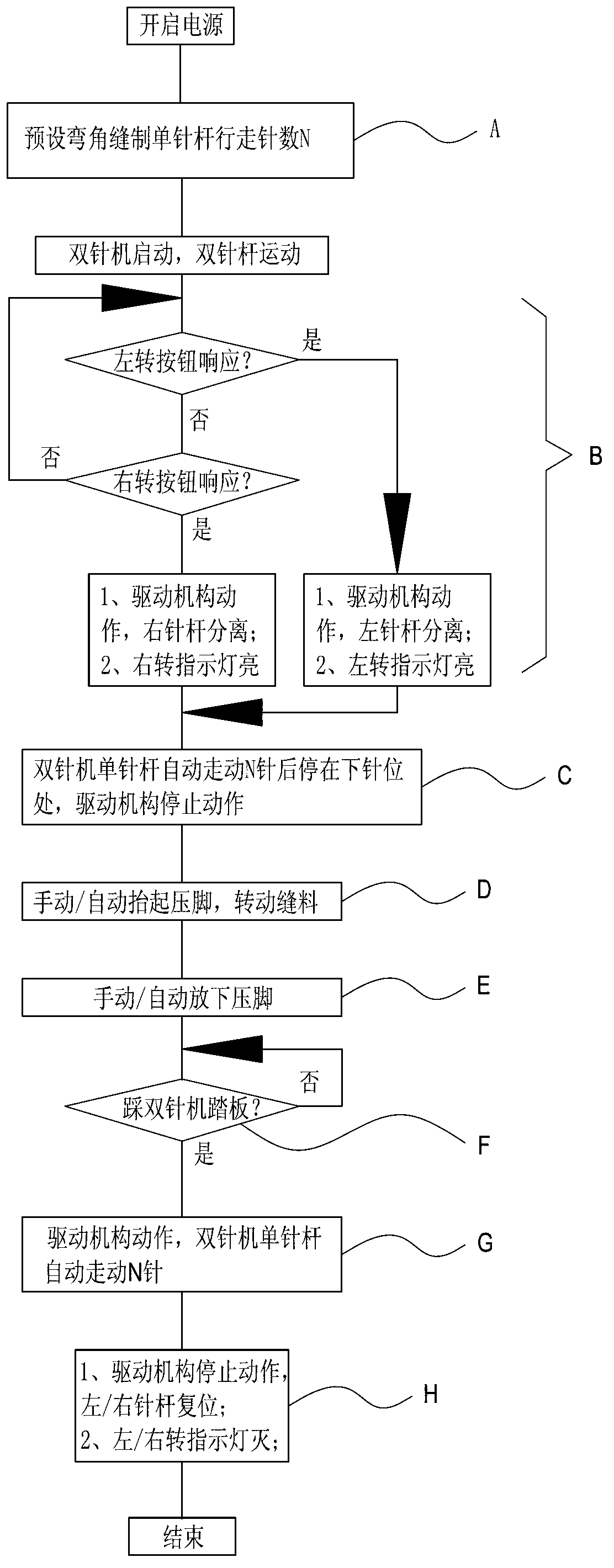

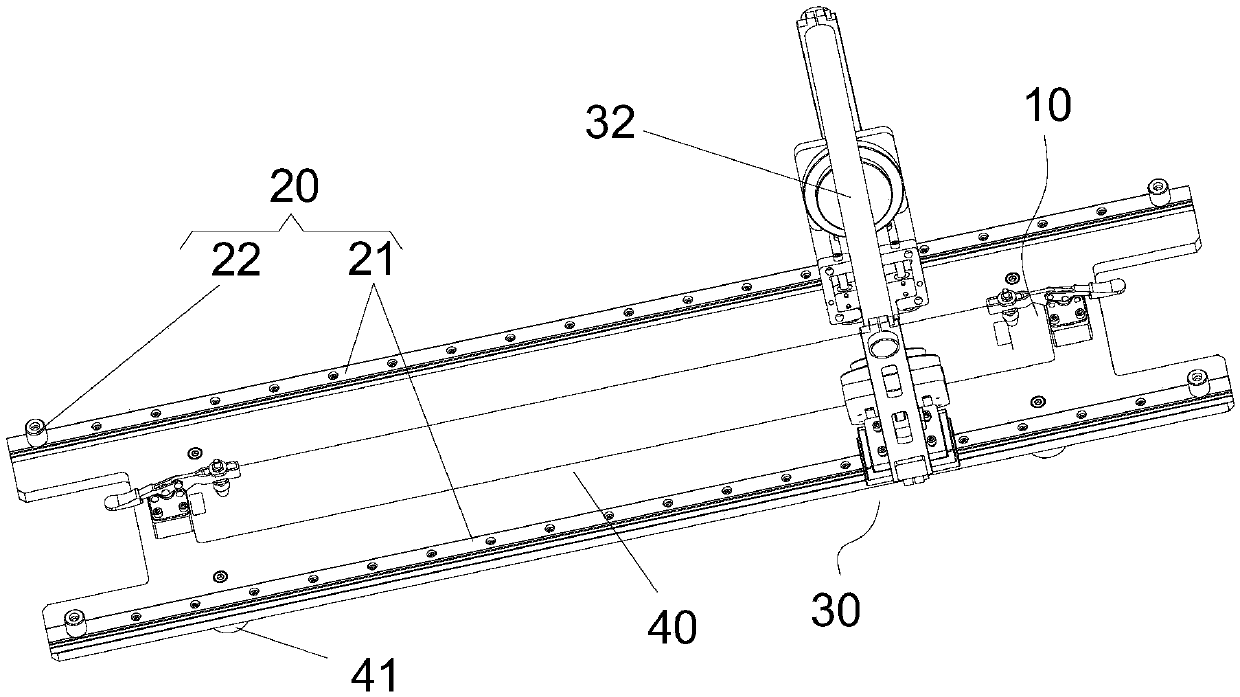

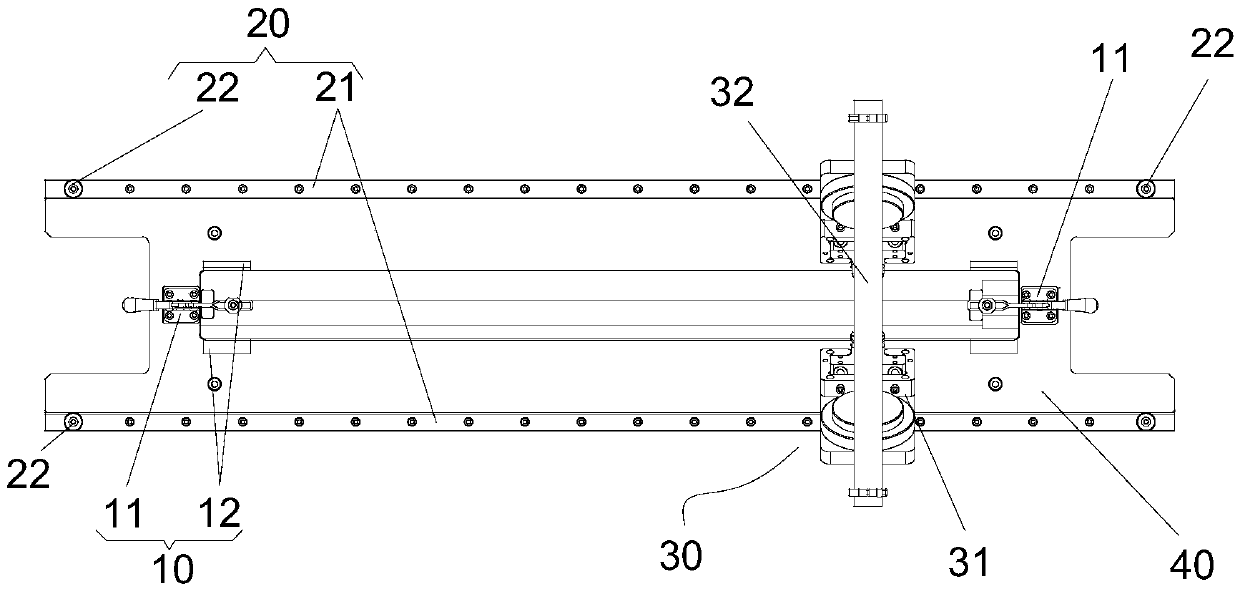

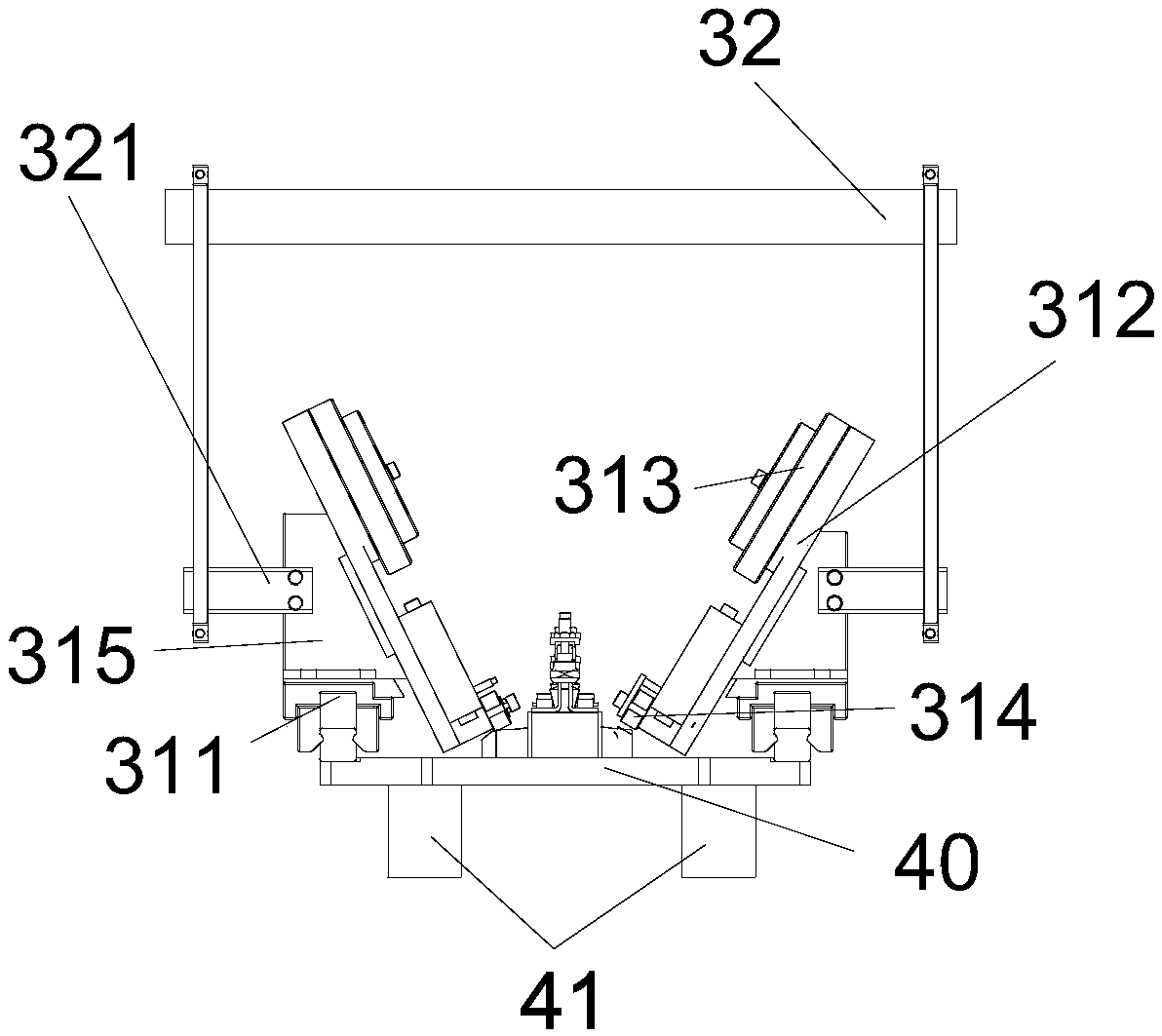

Control method for automatic separation and resetting of needle rods of double-needle machine

ActiveCN103276541ARealize semi-automationQuality assuranceSewing-machine control devicesNeedle positionEngineering

The invention provides a control method for automatic separation and resetting of needle rods of a double-needle machine. The method comprises that a stitch number N of single needle rod walking during corner sewing is preset in a control unit; during corner sewing, a turning button is pressed down, the control unit enables a driving mechanism to act to separate the two needle rods, one of the two needle rods is the working needle rod, and the other needle rod is the separated stopping needle rod; the working needle rod stops at the lower needle position after conducting single needle rod walking for N stitches; a pressing foot of the double-needle machine is lifted, and a sewing material is rotated; the pressing foot is placed down; a control switch is pressed down; the working needle rod conducts the single needle rod walking for N stitches again; and the control unit enables the driving mechanism to stop acting, and the two needle rods are reset under the action of a needle rod resetting assembly. By the aid of the control method, the semi-automation of the corner sewing is achieved, and particularly, the stitch numbers of single needle rod walking before and after rotation of the sewing material during the corner sewing are strictly consistent, so that the quality of the corner sewing is guaranteed, the reworking phenomena caused by the different stitch numbers can be eliminated, and the working efficiency is improved.

Owner:JACK SEWING MASCH CO LTD

Adhesive tape pasting tool

PendingCN109654096AImprove the efficiency of sticking double-sided tapeGuaranteed paste consistencyFastening meansEngineeringControl quality

The invention provides an adhesive tape pasting tool. The adhesive tape pasting tool comprises a positioning mechanism, a guide rail mechanism and an adhesive tape pasting mechanism. The positioning mechanism is used for limiting and fixing a to-be-machined workpiece; the guide rail mechanism is fixed relative to the positioning mechanism in position; and the adhesive tape pasting mechanism is arranged on the guide rail mechanism in a sliding mode and used for loading double-faced adhesive tape and pasting the double-faced adhesive tape to the to-be-machined workpiece. By adoption of the technical scheme, on the basis that the to-be-machined workpiece is positioned well, the double-faced adhesive tape is pasted in the set direction through the adhesive tape pasting mechanism, pasting consistency is ensured, controlled quality is ensured, and return for package and rework are avoided. At the same time, by the adoption of the technical scheme, the efficiency of double-faced adhesive tapepasting operation by workers is improved.

Owner:GREE ELECTRICHEFEI +1

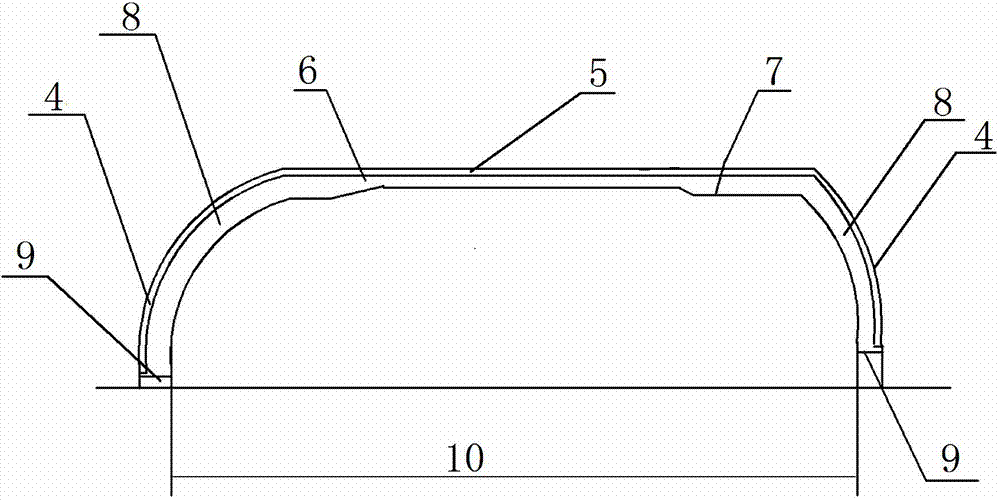

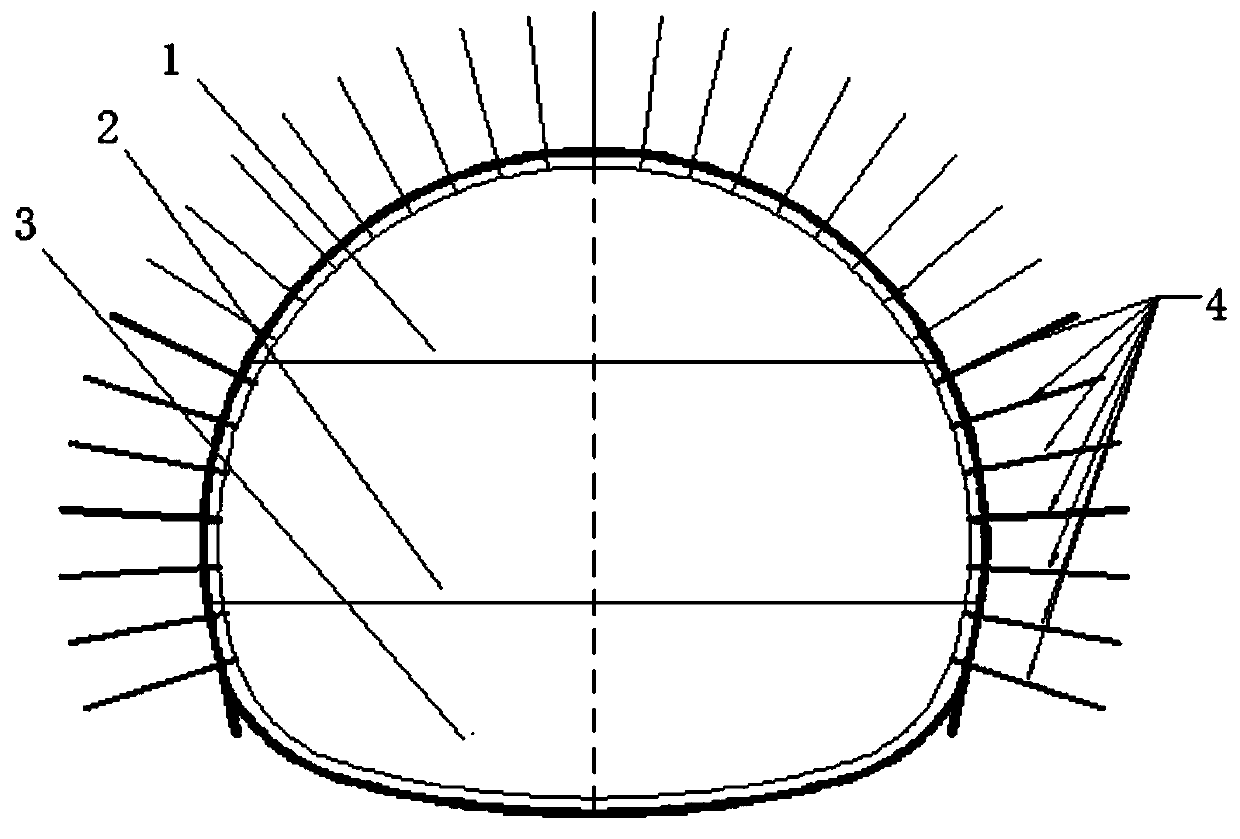

Rubber airbag for manufacturing heat insulating layer of engine

InactiveCN104842479AComplete vulcanizationReduce manufacturing costCoatingsAirbagUltimate tensile strength

The invention relates to a rubber airbag for manufacturing a heat insulating layer of an engine and belongs to the technical field of airbag manufacturing. The rubber airbag for manufacturing the heat insulating layer of the engine comprises a bag body and seal heads at the two ends thereof, wherein the thickness of the bag body is 2 to 4mm; the bag body and the seal heads are integrally formed; one seal head is provided with an inflating device; the inflating device comprises a T-shaped air nozzle, and the T-shaped air nozzle is fixed on the seal head through a pressing plate and a nut; threads are processed on the T-shaped air nozzle, and the threads are matched with the nut. During use, the pressure loss of the rubber airbag is smaller than 0.1MPa and the profile quality and surface smoothness of the heat insulating layer are remarkably improved; since no separating agent is used, interface defects caused by interface pollution are fundamentally eliminated and the product quality is obviously improved; since the difference between material systems of the airbag and the heat insulating layer is greater and the airbag is naturally separated from the heat insulating layer in the air extraction process during demolding, the labor intensity of an operator is reduced and the rubber airbag can be used at 150 DEG C for a long time; the goal of guaranteeing the profile of the heat insulating layer and the product quality of the engine can be achieved.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH +1

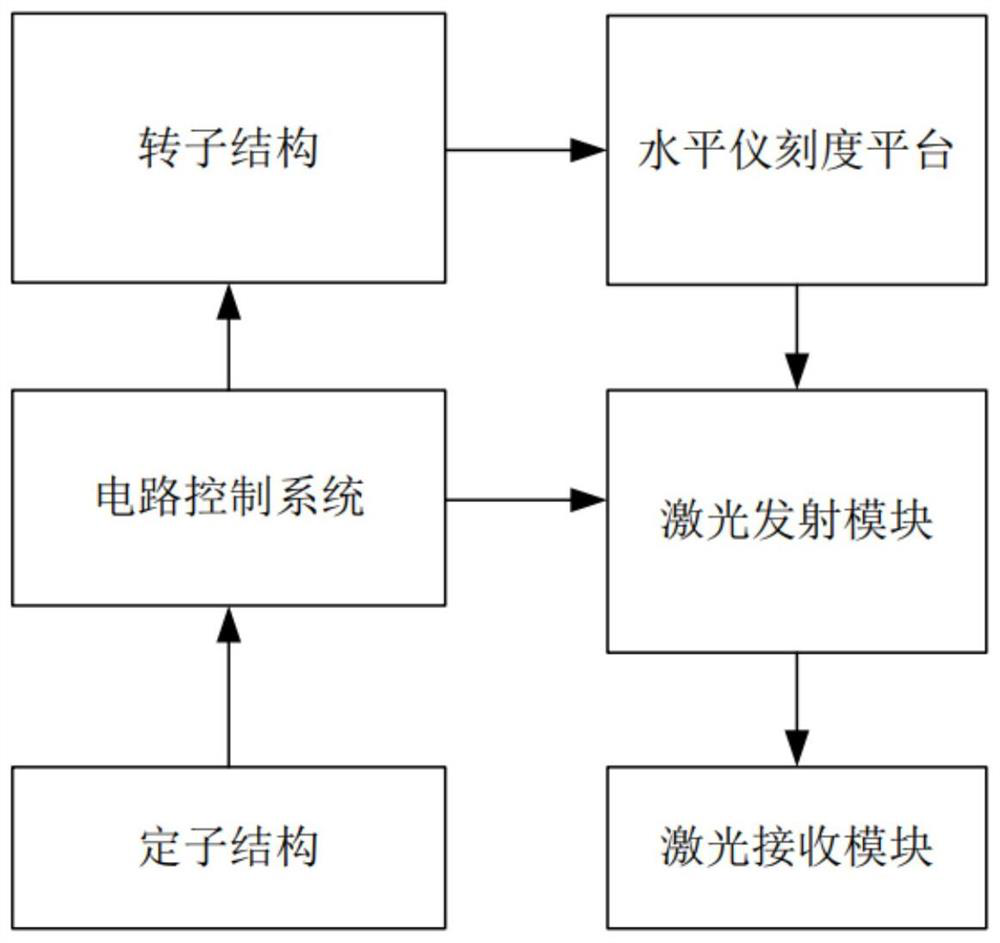

Positioning equipment for reserved holes of multi-storey building pipelines

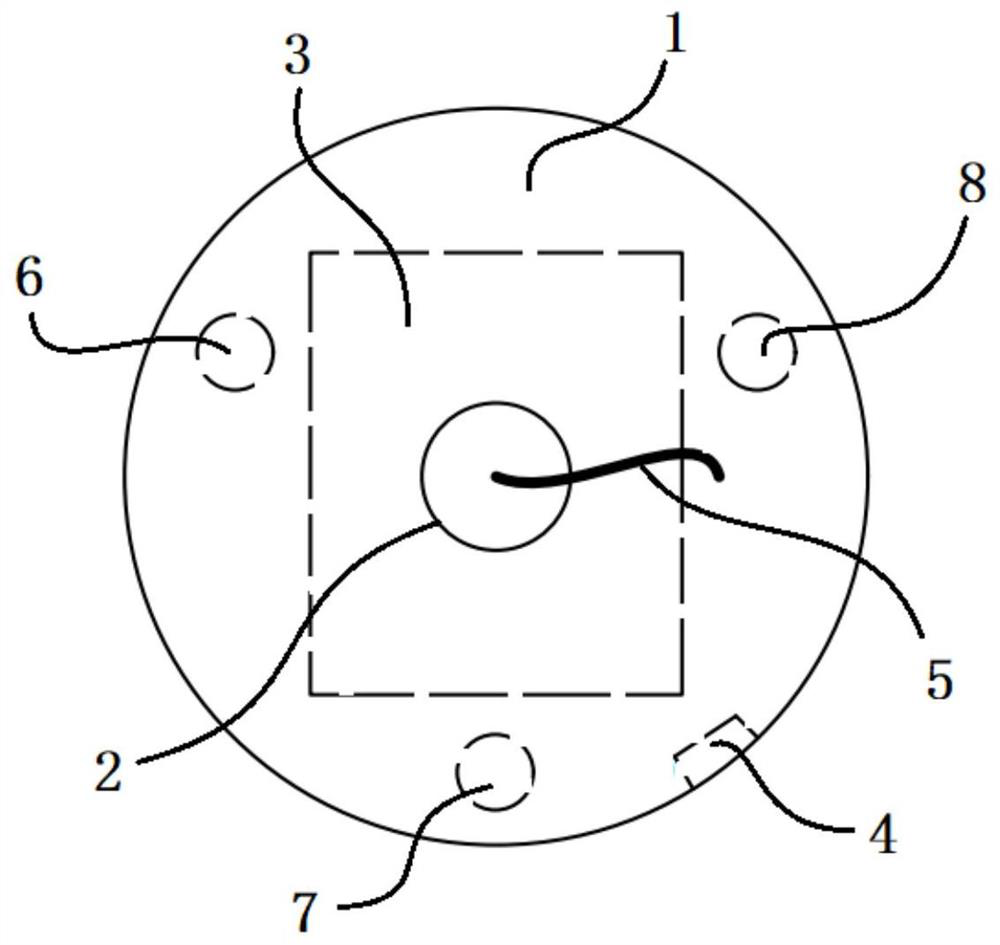

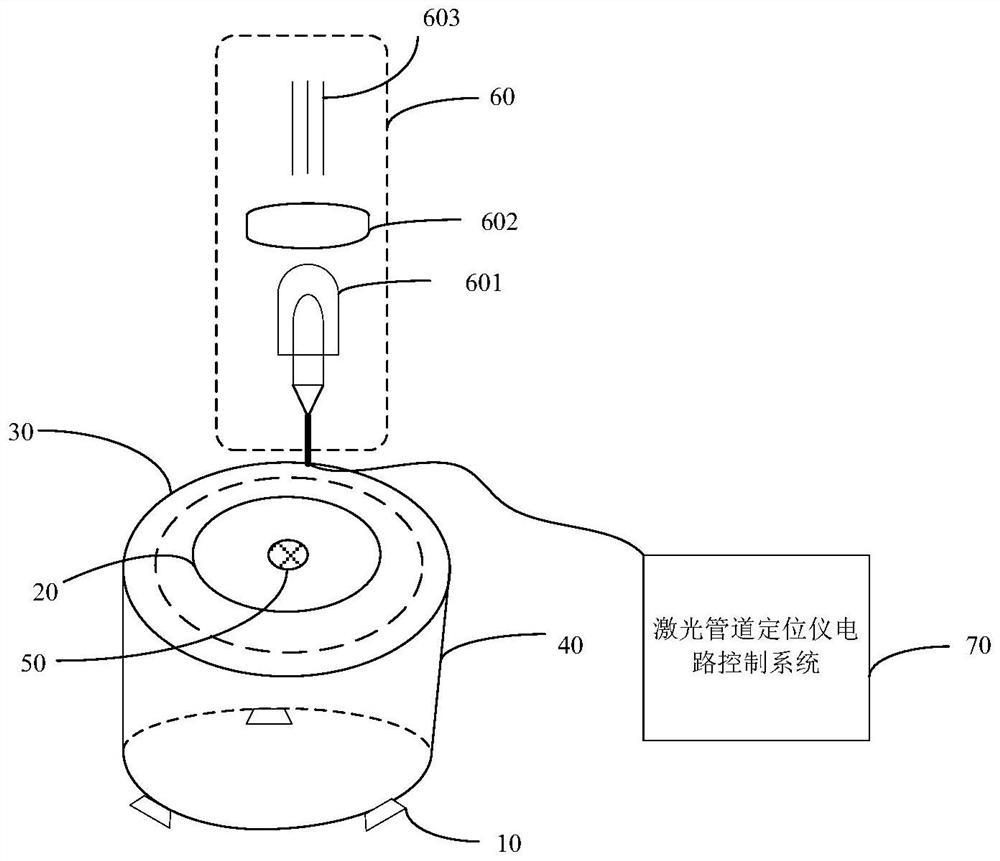

ActiveCN113338640AEliminate reworkAccurate locationThermometers using physical/chemical changesUsing optical meansControl systemRework

The invention provides positioning equipment for reserved holes of multi-storey building pipelines, and relates to the technical field of constructional engineering. The positioning equipment comprises a base, a stator, a rotor, a gradienter scale platform, a laser transmitting module, a gradienter, a circuit control system, a man-machine interaction device and a laser receiving module, wherein the stator is fixedly arranged at the center of the upper surface of the base in the longitudinal direction, the rotor is rotationally connected to the upper end of the stator, the gradienter scale platform is fixedly connected to the upper end face of the rotor, the laser transmitting module is connected to the gradienter scale platform, the gradienter is arranged on the upper surface of the gradienter scale platform, the circuit control system is installed on the base, and the man-machine interaction device is installed on the outer surface of the base. According to the positioning equipment, the positions of the pipelines to be installed can be accurately determined, specifically, the positions of the reserved holes of the pipelines to be installed of all floors can be accurately positioned in sequence in the construction process, the precision can reach the millimeter level or below, the rework phenomenon caused by inaccurate pipeline positioning is eliminated, and the construction cost is greatly reduced.

Owner:CHINA STATE CONSTR ZHONGXIN CONSTR ENG CO LTD

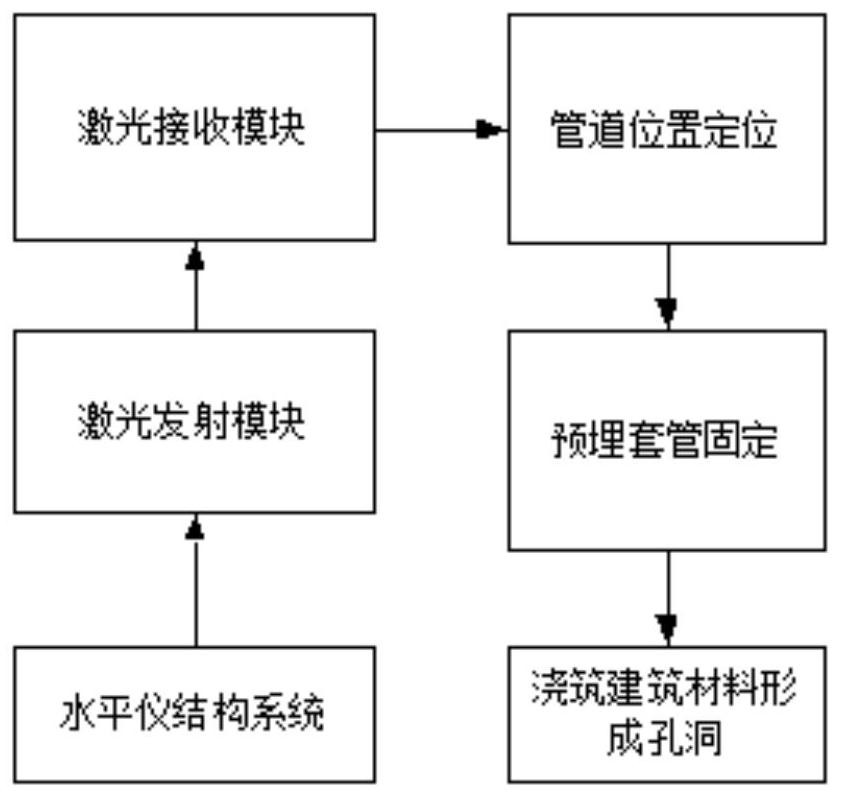

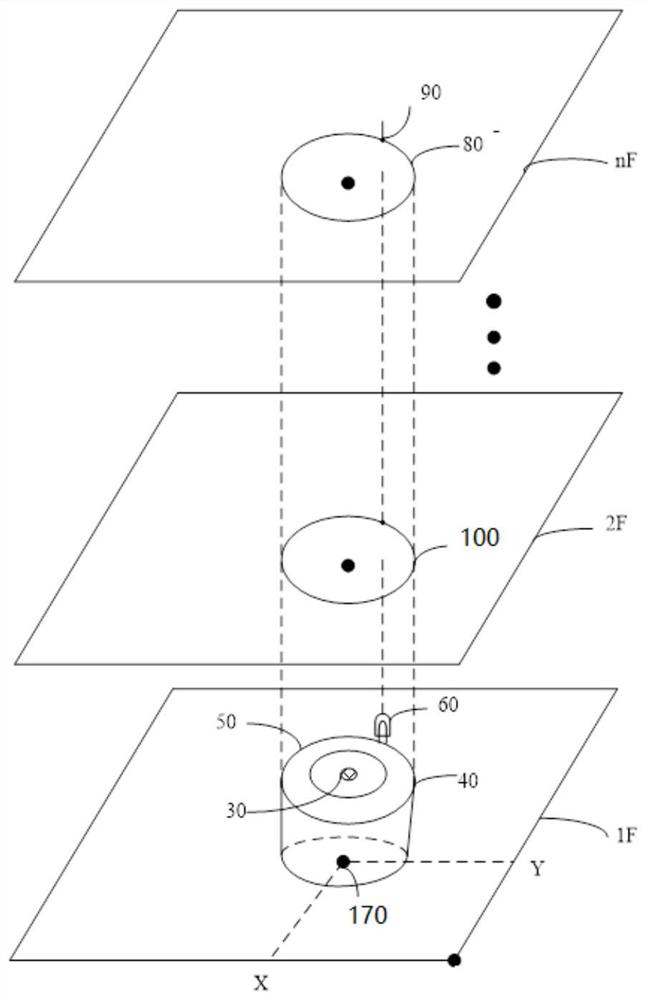

Positioning method for reserved holes of pipelines of multi-storey building

ActiveCN113250475AExtended service lifeReduce leak rateThermometers using physical/chemical changesForms/shuttering/falseworksFloor slabArchitectural engineering

The invention provides a positioning method for reserved holes of pipelines of a multi-storey building, and relates to the technical field of building engineering. The specific construction method comprises the steps that the mounting positions of the vertical pipelines are determined on the upper surface of a floor slab on the bottommost layer of the building, and laser transmitting modules are arranged at the mounting positions; in the formwork erecting process of a floor slab on the second storey, laser receiving modules are fixed to reserved areas, and lasers are transmitted through the laser transmitting modules, so that the laser receiving modules generate position marks which conform to the mounting precision and are in the shapes of embedded sleeves of the reserved holes of the pipelines; the embedded sleeves are placed at the position marks, and the formwork erecting procedure of the floor slab on the second storey is completed; concrete is poured, formwork removal is conducted, and the reserved holes of the floor slab on the second storey are formed at the reserved sleeves; and the steps are repeated, and positioning and pouring of the reserved holes of the pipelines of all the storeys are completed. According to the positioning method, the problem that positioning of the reserved holes of the pipelines of the multi-storey or high-rise building is not accurate can be fundamentally solved, and the pipeline mounting related error and standard requirements can be met.

Owner:CHINA STATE CONSTR ZHONGXIN CONSTR ENG CO LTD

Method for strengthening bonding strength of carbon fiber/phenolic-nitrile rubber material

InactiveCN104845540AHigh bonding strengthImprove pressurization efficiencyAdhesive processes with surface pretreatmentAdhesive processes with adhesive heatingFiberCarbon fibers

The invention discloses a method for strengthening the bonding strength of a carbon fiber / phenolic-nitrile rubber material. Layers of the material are bonded by the steps of brush coating, bonding, pre-pressing and curing, a fractional thermal pre-pressing process is adopted for a bonding process, and the number of the layers which are thermally pre-pressed every time is controlled to be within 3, so that the pressure loss of pressure of an airbag in a transmission process can be reduced; by the use of an airbag product employing a soft silicone rubber material, the pressurization efficiency of the airbag can be improved. Moreover, small molecules of a solvent, air and the like in a carbon fiber material and between the layers can be removed by vacuumizing, so that the aim of ensuring the interlayer bonding quality of the product is fulfilled.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH +1

A composite insulation roof structure and a realization method thereof

PendingCN108894436AEliminate reworkReduce material waste and labor lossRoof covering insulationsBuilding material handlingRebarReinforced concrete

A composite heat preservation roof structure and its realization method, the invention comprises a reinforced concrete base layer and a cement mortar leveling layer paved on the reinforced concrete base layer, A metal reinforce bar is arranged on a reinforced concrete base lay and a cement mortar leveling layer, the cement mortar leveling layer is sequentially provided with a waterproof layer anda composite insulation hanging tile integral plate, the composite insulation hanging tile integral plate passes through a metal reinforcing bar and is strengthened and fixed on the waterproof layer inan adhesive manner, and the roof tile is fixed on the hanging tile strip of the composite insulation hanging tile integral plate by screws; As compare with that prior art, after the leveling lay of the slope roof is finished, a metal reinforcing bar is firstly implanted into the structure, a waterproof lay is then coated, a composite heat preservation hanging tile integral plate is installed on the waterproof layer, holes are drilled on the hanging tile bar, leveling and fixing are carried out, and finally the roof tile is fixed on the hanging tile bar; Applicable to all kinds of modelling slope roof construction, greatly reduce the use of non-renewable or difficult to renewable resources, is the advocacy of green building engineering.

Owner:北京利泰装饰工程有限公司

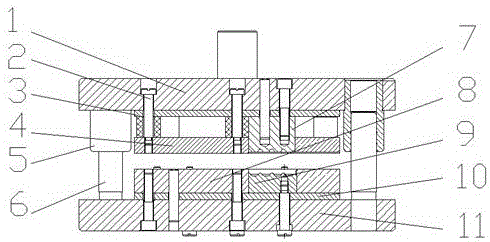

Automobile intercooler pipe grid forming die

InactiveCN106493233AGuaranteed smooth assemblyEliminate reworkShaping toolsPerforating toolsPunchingIntercooler

The invention discloses an automobile intercooler pipe grid forming die. The automobile intercooler pipe grid forming die comprises an upper die plate, a guiding sleeve and a lower die plate; spring screws are installed in the upper die plate; an upper cushion plate is fixed below the upper die plate; a pressing plate is arranged below the upper cushion plate; a male die is installed in the middle of the pressing plate; a guiding column is connected to the lower portion of the guiding sleeve; the upper portion of the guiding sleeve is fixedly connected with the upper die plate; a lower cushion plate is fixed to the lower die plate; the bottom of the guiding column is connected with the lower die plate; a female die is installed above the lower cushion plate; and a forming piece top plate is connected to the female die. After punching of a convex closure formed through the forming die, the surface intersection line of hole opening four-corner arcs and convex closure four-corner cones is lower than a straight side intersection line; in the assembling process of a pipe grid subjected to punch forming through the above forming method, after a pipe penetrates a pipe grid hole, the elasticity of a straight side is restored so that deformation is avoided, while reworking is eliminated, the product assembly quality and the production efficiency are improved, and the forming method has good reference significance in parts with similar using requirements.

Owner:GUIZHOU GUIHANG AUTOMOTIVE COMPONENTS

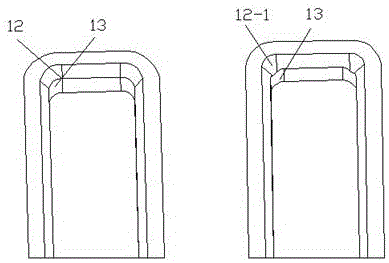

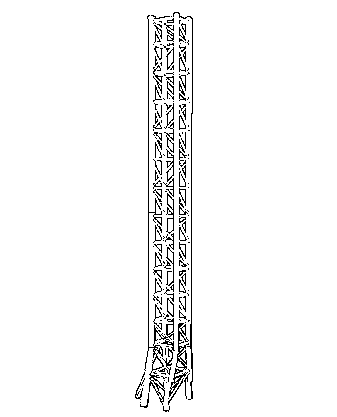

Machining technology for tube supports of non-allowance circular structure steel tubes and tube support structure

InactiveCN103128503AImprove construction efficiencyImprove welding qualityTowersDesign softwareEngineering

The invention discloses a machining technology for tube supports of non-allowance circular structure steel tubes. The machining technology comprises: step A, understanding machining performances and parameters of machine equipment; step B, using three-dimensional design software for performing 1:1 modeling and setting out on a structure tube support; step C, performing nesting on a structure steel tube and designing a machining diagram through relevant design software, and outputting machining information and confirming relevant parameters; and step D, inputting machining parameters through a tube machining machine, performing non-allowance blanking on the structure steel tube, and achieving one-step cutting molding of end forms and grooves. By means of the machining technology for tube supports of non-allowance circular structure steel tubes, the construction efficiency and the welding quality are improved, reworking is eliminated, tubing is saved, the production cost is reduced, and the construction period is shortened.

Owner:COSCO DALIAN SHIPYARD

Carbon fiber / phenolic-nitrile rubber material and preparation method thereof

InactiveCN104890256AImprove product quality stabilityEliminate individual product differencesDuctilityPhenols

A carbon fiber / phenolic-nitrile rubber material and a preparation method thereof belong to the field of rubber composite material preparation. The material is prepared from the following components by weight: 50-55% of carbon fiber, 18-25% of phenolic aldehyde and 22.5-30% of nitrile rubber. The carbon fiber is weaved by a weft knitting process, and presents double back texture. The density of the material is 1.38 g / cm<3>. The preparation method is as below: calculating the amount of carbon fiber by equation, weaving by using carbon fiber, weighing the knitted fabric, determining the amount of phenolic and nitrile rubber according to the density, dissolving nitrile rubber and phenol, adding carbon fiber for gumming, and then drying to obtain the desired material. The carbon fiber / phenolic-nitrile rubber material provided by the invention can significantly improve the resistance to erosion, and has high ductility.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH +1

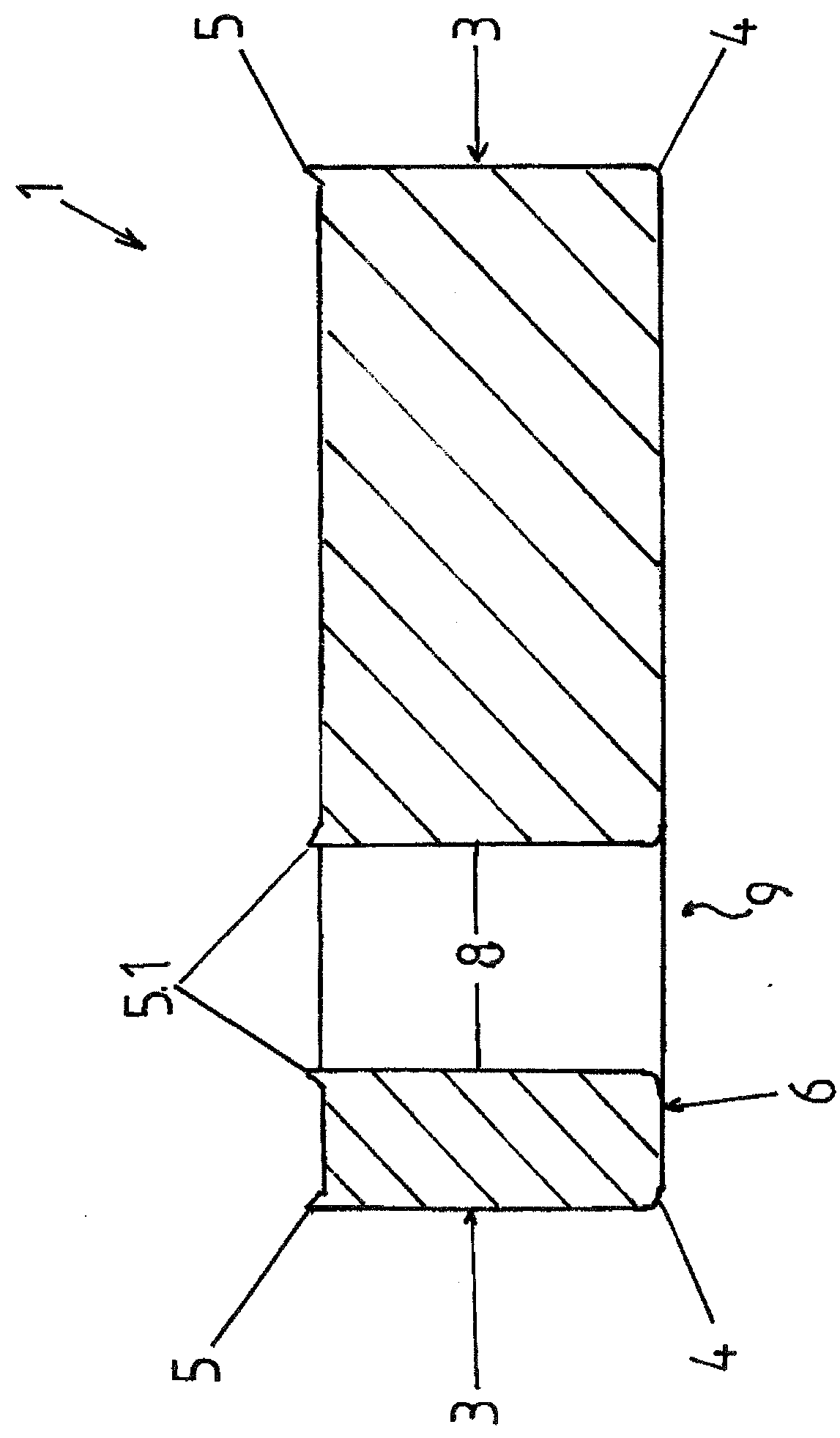

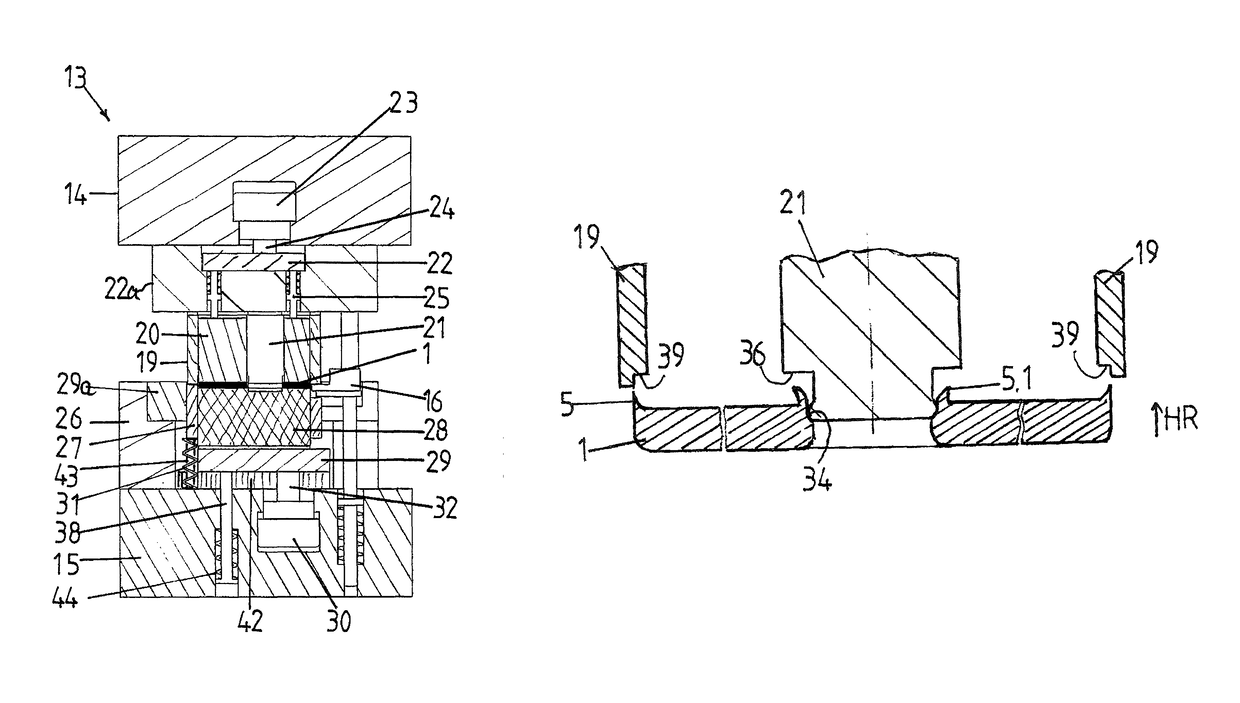

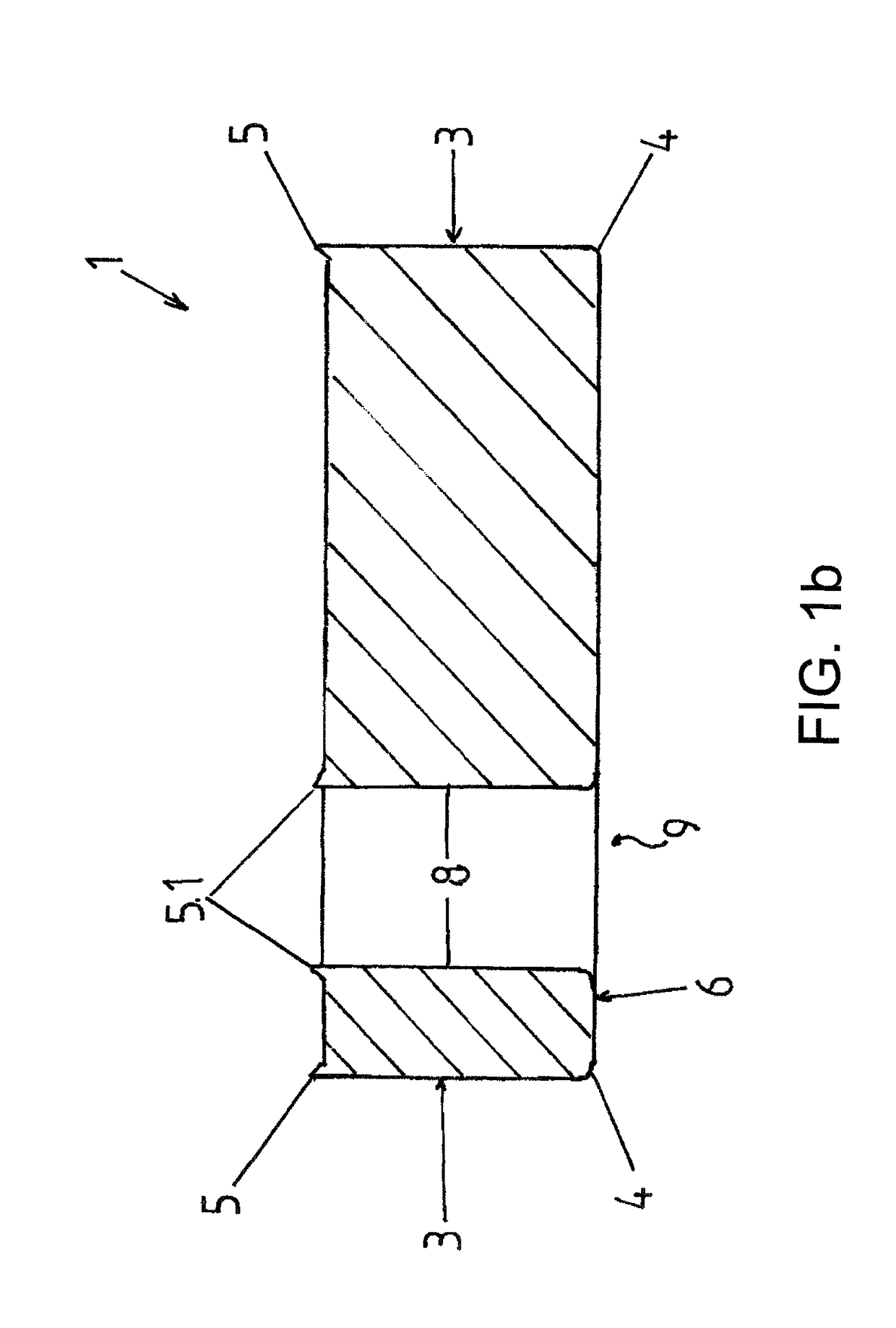

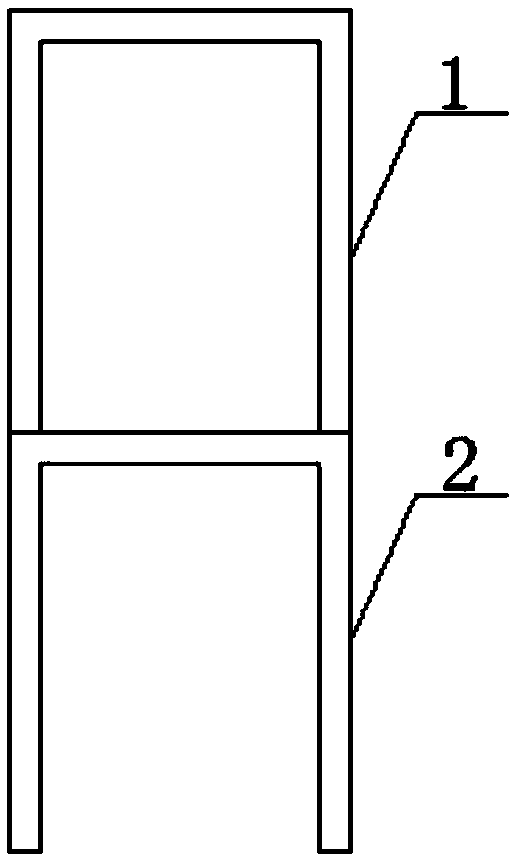

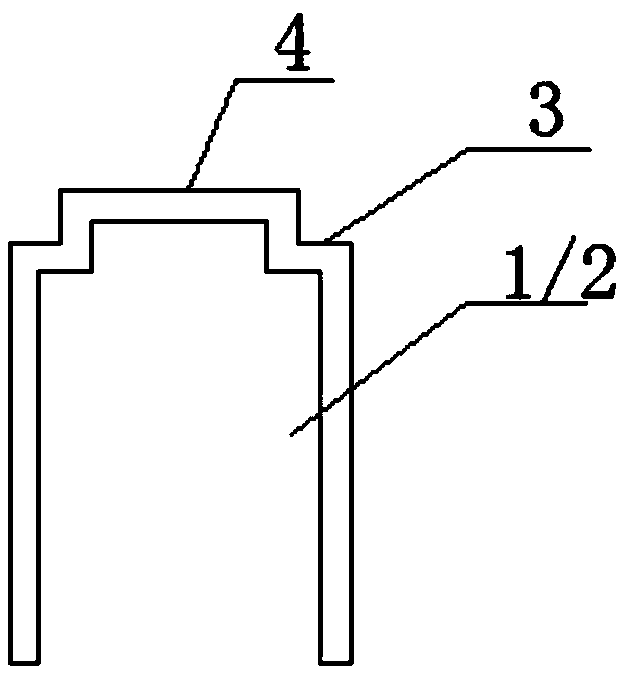

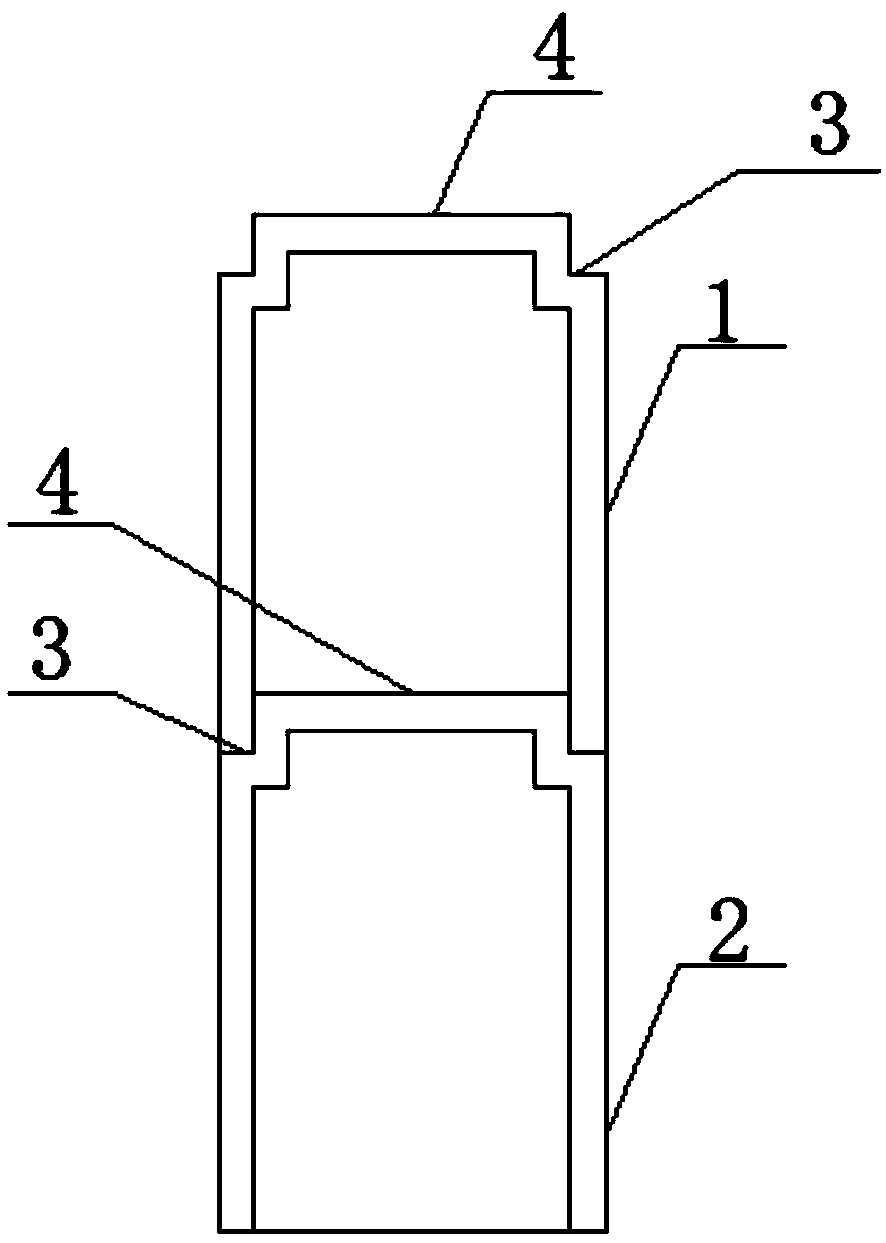

Device and method for shaping sheared edges on stamped or fine-blanked parts having a burr

A device and a method for shaping sheared edges on stamped or fine-blanked parts having a burr include at least one cutting stage and at least one forming stage. The forming stage includes a shaping punch which has a shaping region for smoothing the sheared edge of the outer or inner contour of the workpiece to the net shape and an embossing shoulder for mashing the burr of the outer or inner contour. The shaping punch is configured so that the shaping region initially bends the burr on the outer or inner contour away from the sheared edge, then seizes the sheared edge for widening, wherein the embossing shoulder of the shaping punch mashes the burr on the outer or inner contour when the widening on the workpiece has ended and flattens the embossing bead, created during mashing, during separating of the shaping punch from the workpiece.

Owner:FEINTOOL INT HLDG

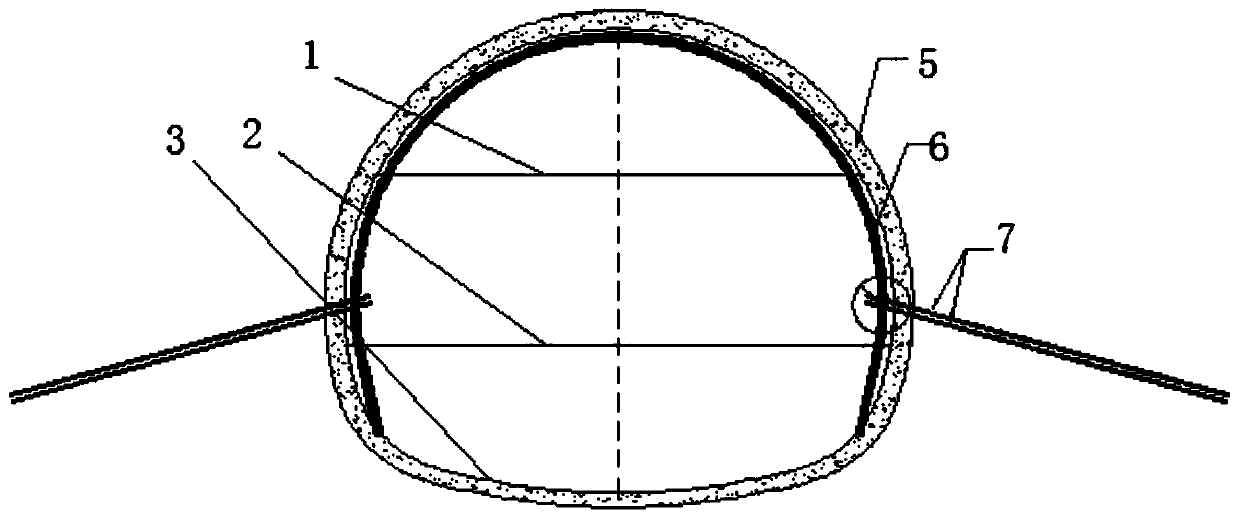

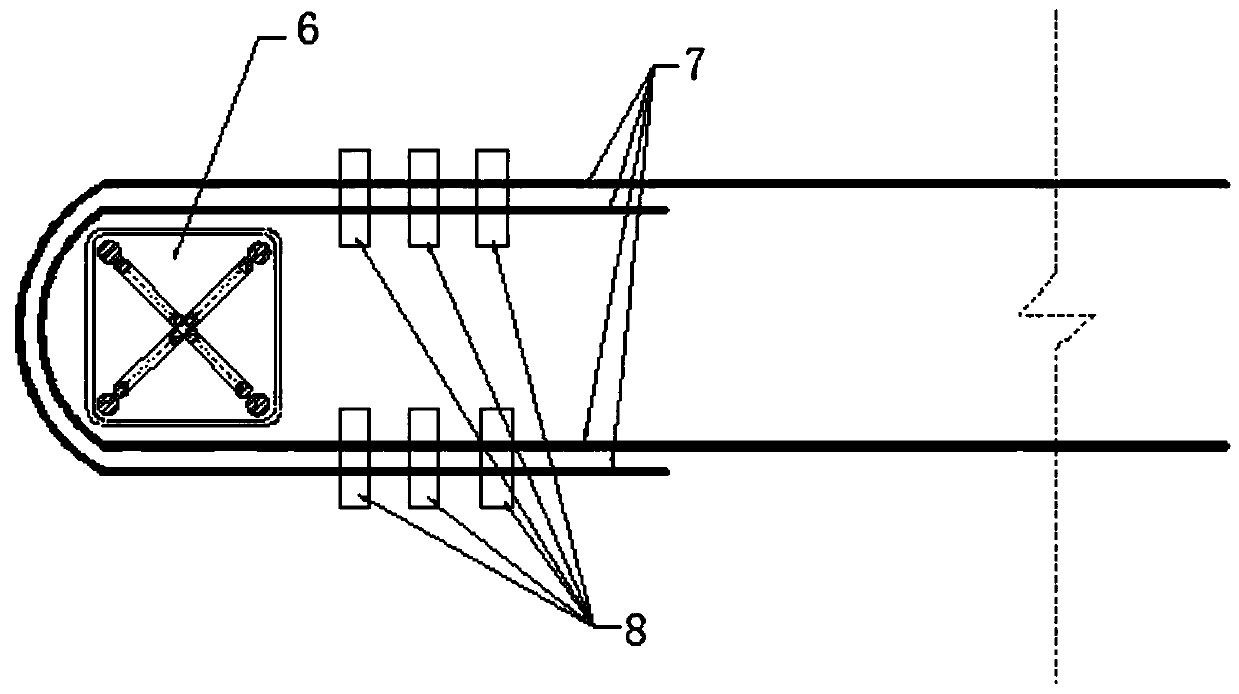

Spaced secondary arch frame and long anchor cable lock foot composite construction method for supersoft rock tunnel

PendingCN111577355AEliminate reworkReduce construction costsUnderground chambersTunnel liningRebarTunnel construction

The invention discloses a spaced secondary arch frame and long anchor cable lock foot composite construction method for a supersoft rock tunnel, and relates to the technical field of tunnel construction protection. The method comprises: performing construction by a three-step method, wherein the excavated reserved settlement deformation quantity is 500 mm, and advanced small pipes are inserted inthe boundaries of the two side edges and grouting is conducted before middle and lower steps are excavated; a temporary inverted arch primary support is applied after excavation; a grid arch frame isarranged at an interval of 6.0 m; after the two sides of the tunnel are punched by an anchor cable machine, the anchor cable is mounted with 600 mm reserved; grouting is conducted by sulphate aluminium cement, a prestressing force of 3 to 5 tons is applied after solidification for 2 hours, the adjacent two anchor cables are locked by three pairs of anchor cable clamps and are sprayed smoothly withconcrete; and secondary lining is applied by a double-layer reinforced concrete structure to complete construction. On the basis of the first primary support, a composite method of the spaced secondary arch frame and the long anchor cable lock foot is adopted, so that clearance-intrusion, even landslide accident, caused by big deformation of the primary support is avoided, and safety risk is controlled.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

Device and method for shaping sheared edges on stamped or fine-blanked parts having a burr

A device and a method for shaping sheared edges on stamped or fine-blanked parts having a burr include at least one cutting stage and at least one forming stage. The forming stage includes a shaping punch which has a shaping region for smoothing the sheared edge of the outer or inner contour of the workpiece to the net shape and an embossing shoulder for mashing the burr of the outer or inner contour. The shaping punch is configured so that the shaping region initially bends the burr on the outer or inner contour away from the sheared edge, then seizes the sheared edge for widening, wherein the embossing shoulder of the shaping punch mashes the burr on the outer or inner contour when the widening on the workpiece has ended and flattens the embossing bead, created during mashing, during separating of the shaping punch from the workpiece.

Owner:FEINTOOL INT HLDG

Mounting method of embedded GRC boards

PendingCN109267727AImprove installation qualityImprove installation speedBuilding constructionsShock resistanceEngineering

The invention belongs to the technical field of production and construction of exterior wall materials in the field of buildings, and discloses a mounting method of embedded GRC boards. An upper protruding part protruding out of the second GRC board is directly embedded in the first GRC board, and the step is repeated until multiple transverse or vertical lines are mounted. By reserving the concave and convex style during production, a splicing port of two materials is directly embedded, the requirement for paying off is reduced, the technological difficulty for workers is also lowered, and the phenomenon that rework is caused when a mounting face is out of flatness is greatly reduced or even removed, and the surface error of the flatness and perpendicularity of a mounting completion facecan be controlled within the range of minus 1 mm to 1 mm. A traditional mounting method of directly splicing two linear materials is changed into the method of directly embedding two upper concave andconvex materials, hanging is firm, the shock resistance is strong, three-dimensional adjustment is automatically completed, the structure is simple, and the quality safety and the exterior decorationeffect are reinforced.

Owner:陕西旭德节能新材料有限公司

A kind of accurate pre-buried water supply and drainage casing and construction method based on bim and aluminum alloy formwork

ActiveCN106481880BGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesProduction drawingShop drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

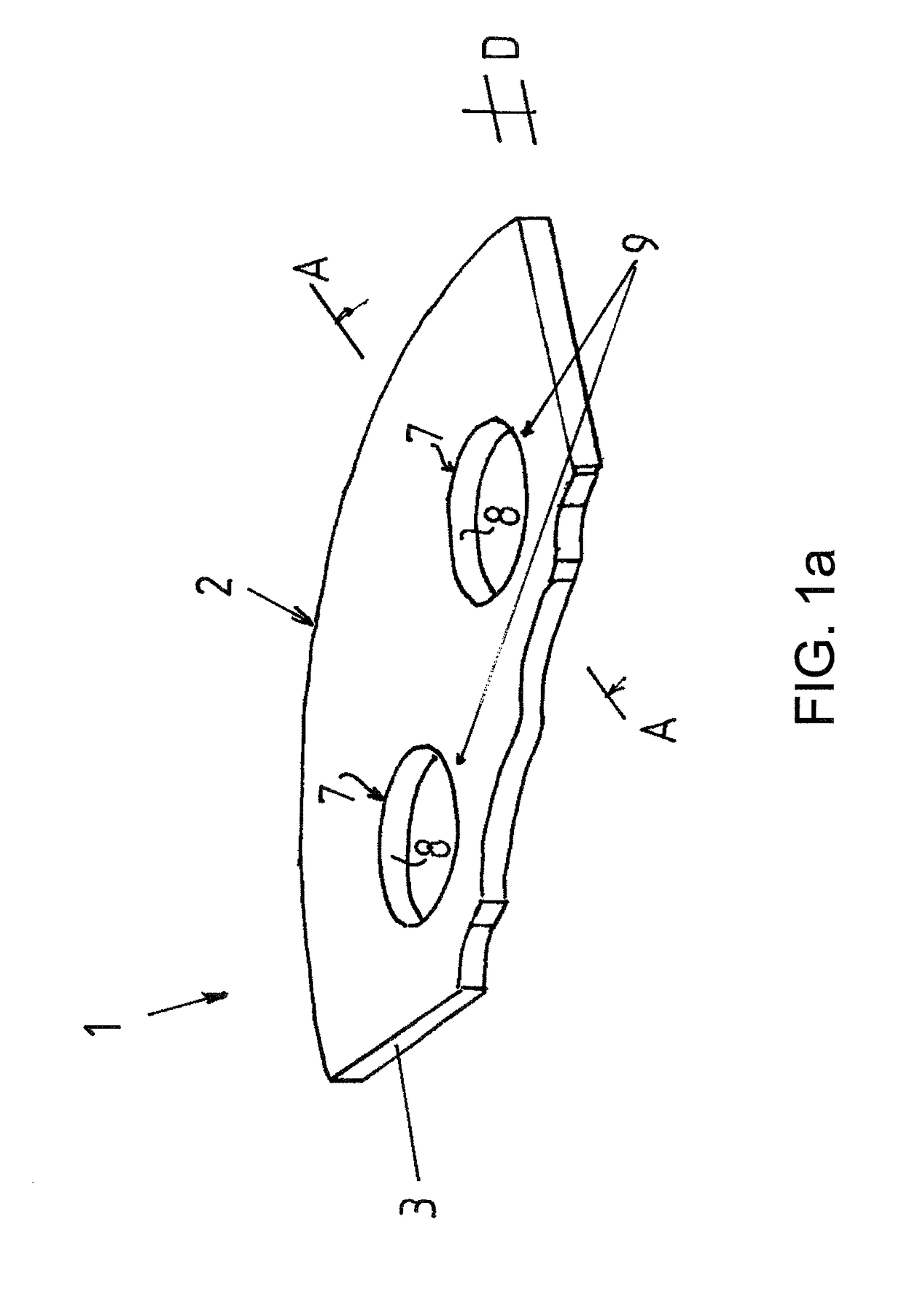

Splice plate with a cam lock

A splice plate for joining and aligning extruded trim strips used in suspended ceiling islands and fascias. The splice plate has at least one cam lock connected to a base plate by a fastener. The fastener passes through an aperture in the cam lock and an aperture formed by a projection in the base plate that projects a distance from the face of the base plate. To prevent deformation of the trim strips, the cam lock and base plate may each include bend lines forming an obtuse angle wherein the obtuse angle of the cam lock is less than the obtuse angle of the base plate.

Owner:WORTHINGTON ARMSTRONG VENTURES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com